Preparation method of short-process titanium alloy Ti-Ni-Nb

A titanium alloy and short-process technology, which is applied in the field of short-process titanium alloy Ti-Ni-Nb preparation, can solve the problems of high energy consumption and low material yield, and achieve uniform composition, high quality, and shortened process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

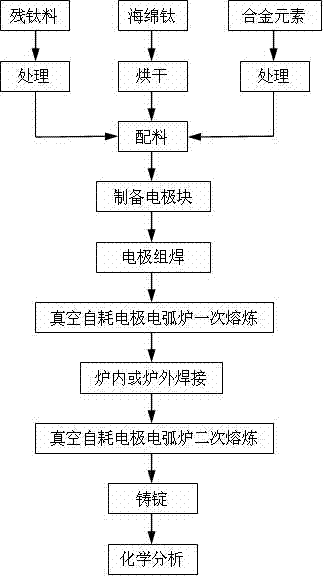

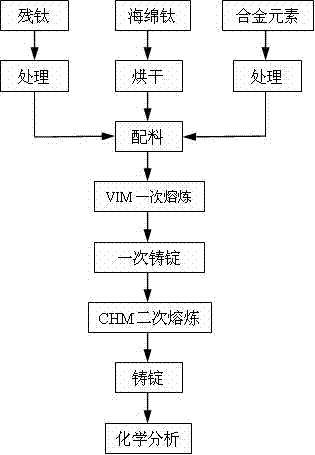

[0019] Below in conjunction with accompanying drawing, short-flow process titanium alloy of the present invention Ti-Ni-Nb The specific examples of the preparation method are described as follows.

[0020] A short process titanium alloy Ti-Ni-Nb The preparation method is made of crucible-type vacuum induction melting technology and the cold-bed furnace melting technology of titanium and titanium alloy, has the following steps:

[0021] a) Prepare raw materials according to the composition of Ti-Ni-Nb alloy, and pretreat the raw materials; residual titanium materials: including residual titanium scraps and titanium scraps, which need to be of the same grade, and the processed particle size is basically the same as that of sponge titanium. After degreasing 1. Standby after deoxidizing skin treatment; the titanium sponge and alloy elements are dried in a vacuum drying oven to remove the moisture adsorbed on the surface. Drying conditions: temperature is about 120~180°C; vacuum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com