Nanometer filler for abrasion-resistant coatings and method for preparing nanometer filler

A kind of wear-resistant coating and nanotechnology, applied in the direction of coating, etc., can solve the problems of poor toughness and other problems, and achieve the effect of solving the problem of organic-inorganic phase interface fusion, preventing agglomeration, and improving toughness and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

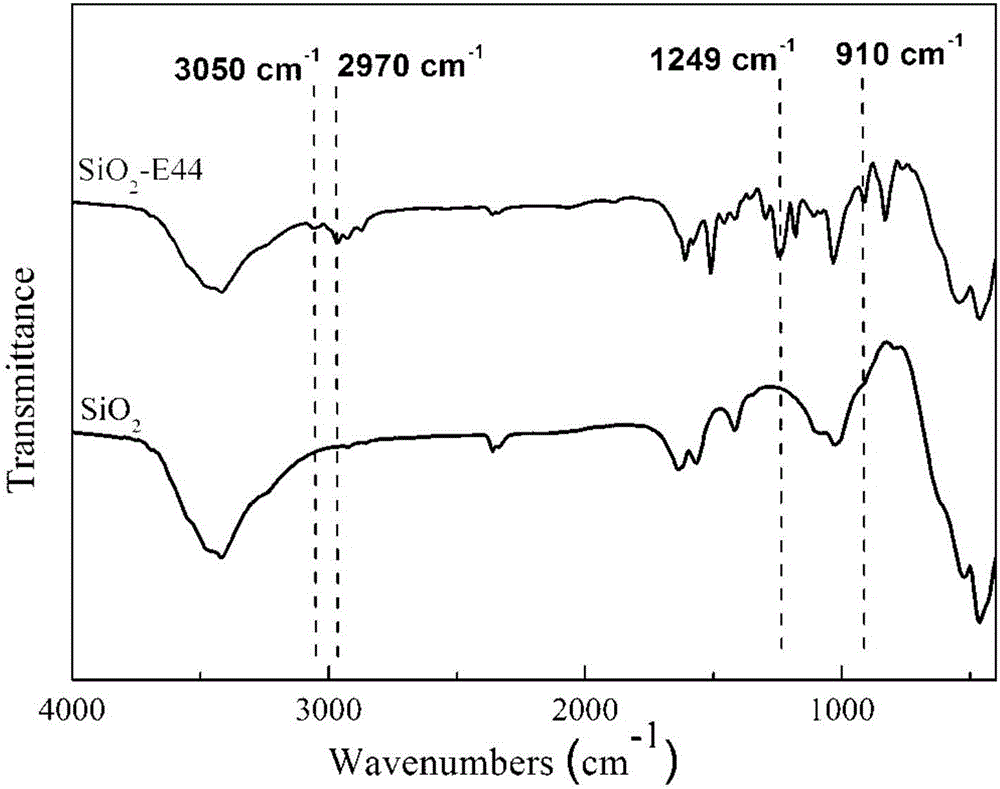

[0040] Put 100g of dry nano-silica with 30% surface hydroxyl content, 30g of anhydrous hexamethylene diisocyanate dimer, and 1000ml of anhydrous toluene in a dry flask, extract the gas in the flask and fill it with N 2 As a protective gas, the reaction is complete after stirring at room temperature for 10 minutes at high speed, and then 80g of anhydrous epoxy resin in toluene solution is dropped into the flask at a rate of 30 drops / min at 30°C, and the temperature rises to Re-reaction at 150°C, the reaction time is 15h, and after the reaction is completed, repeated centrifugal washing with anhydrous toluene to remove unreacted hexamethylene diisocyanate trimer and epoxy resin, suction filtration and drying to obtain surface grafting Epoxy nano silica.

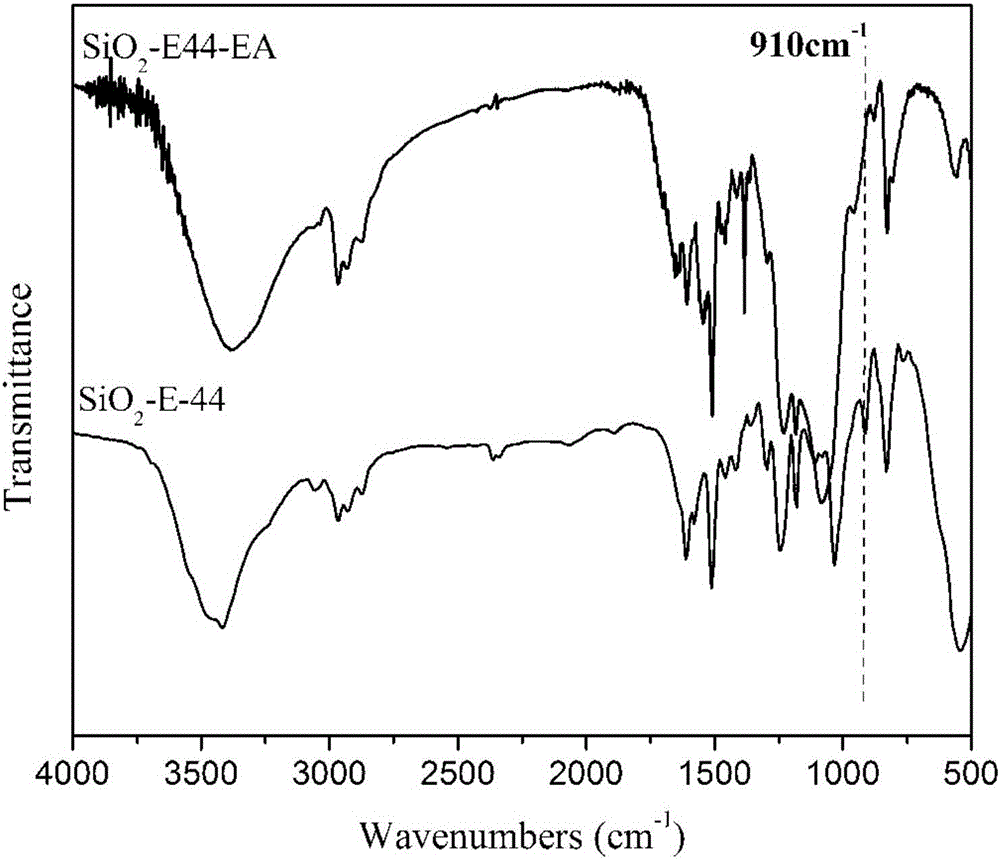

[0041] Place 100g of nano-silica grafted with epoxy resin on the surface and 500ml of anhydrous toluene in a dry three-necked flask, and then drop 80g of ethanolamine into the three-necked flask at a rate of 30 drops / min under magn...

Embodiment 2

[0044] Put 100g of dry nano-silica with a surface hydroxyl content of 40%, 40g of anhydrous hexamethylene diisocyanate trimer, and 500ml of anhydrous xylene in a dry flask, and then fill the flask with N 2 As a protective gas, the reaction is complete after stirring at room temperature for 30 minutes at high speed, and then 100 g of anhydrous epoxy resin in xylene solution is dropped into the flask at a rate of 10 drops / min at 60°C, and the temperature rises after dropping Re-react at 100°C. The reaction time is 24h. After the reaction is completed, it is washed repeatedly with anhydrous xylene to remove the unreacted hexamethylene diisocyanate trimer and epoxy resin. The surface is obtained by suction filtration and drying. Nano silica grafted with epoxy resin.

[0045] Put 100g of nano-silica grafted with epoxy resin on the surface and 500ml of anhydrous xylene in a dry three-necked flask, and then under the action of magnetic stirring at room temperature, 100g of n-butylamine a...

Embodiment 3

[0048] Put 100g of dry nano-silica with 60% surface hydroxyl content, 50g of anhydrous hexamethylene diisocyanate trimer, and 500ml of anhydrous toluene in a dry flask, and then fill the flask with N 2 As a protective gas, the reaction was completed after stirring at room temperature for 20 minutes at high speed, and then 150g of anhydrous epoxy resin in toluene solution was dropped into the flask at a rate of 60 drops / min at 30°C, and the temperature rose to Re-reaction at 200°C, the reaction time is 8 hours, and after the reaction is completed, repeated centrifugal washing with anhydrous acetone to remove unreacted hexamethylene diisocyanate trimer and epoxy resin, suction filtration and drying to obtain surface grafting Epoxy nano silica.

[0049] Place 100g of nano-silica grafted with epoxy resin on the surface and 500ml of anhydrous toluene in a dry three-necked flask, and then drop 50g of triethylamine at a rate of 60 drops / min at 90°C under magnetic stirring. Put it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com