Anti-corrosion temperature sensor

A temperature sensor and corrosion-resistant technology, used in thermometers, thermometer parts, instruments, etc., can solve the problems of protecting the shell from rusting, polluting the test environment, complex structure, etc., to reduce heat loss and corrosion resistance. good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

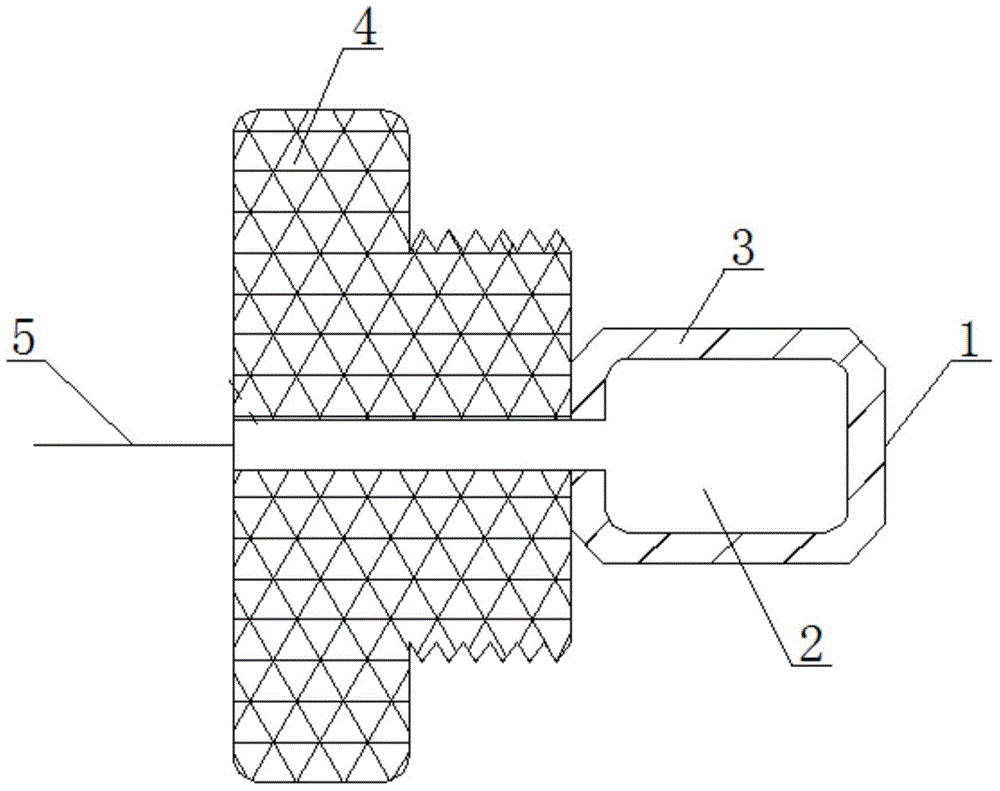

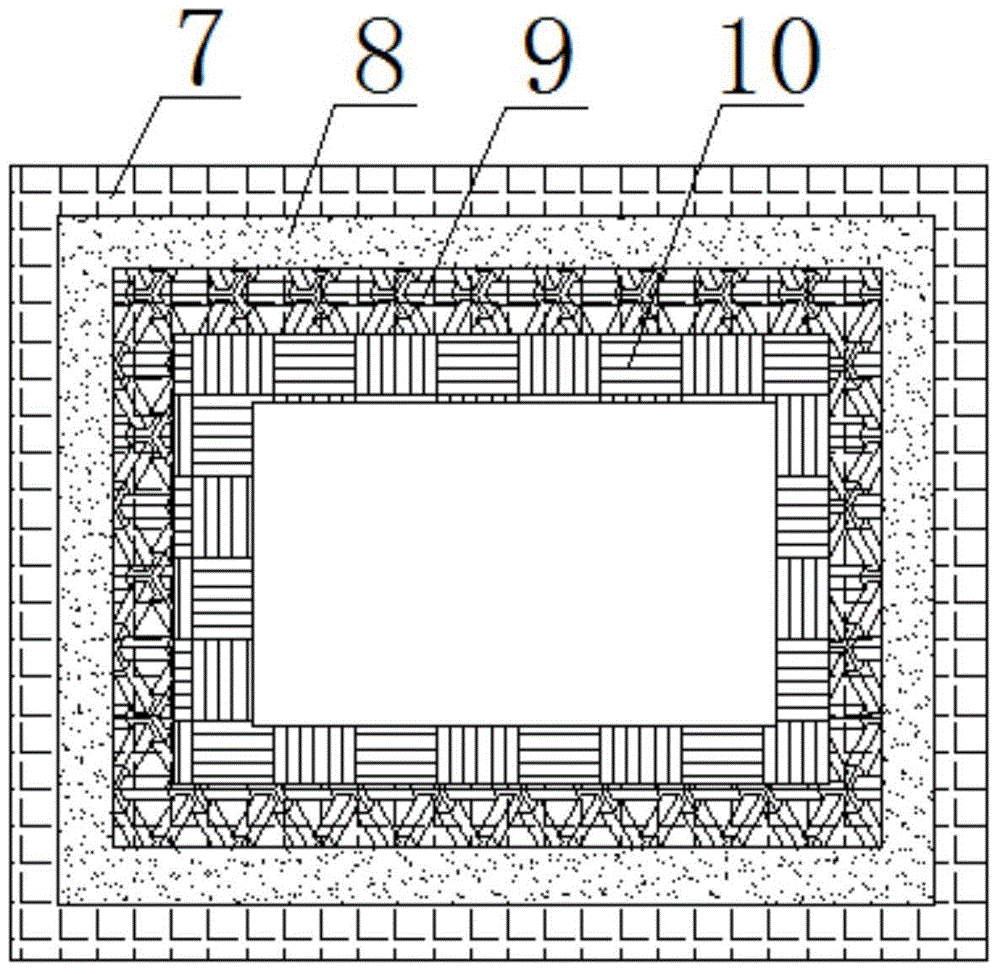

[0016] A corrosion resistant temperature sensor such as figure 1 As shown, it includes a body 1 and a plug 4 that are connected to each other. The body 1 is composed of a protective shell 3 and a thermistor 2. The thermistor 2 is located in the protective shell 3 and leads out the plug 4 through a wire 5. protective casing such as figure 2 As shown, it includes a stainless steel layer 7, a graphite layer 8, an active metal layer 9 and a thermally conductive insulating material layer 10 from outside to inside, wherein the active metal refers to a metal that is more active than stainless steel.

[0017] Preferably, the plug is a PPR plug, which has good heat insulation performance and small heat absorption, which can reduce heat loss during heat transfer.

[0018] Preferably, the thermally conductive insulating material layer is thermally conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com