Aluminum casting alloy with strong mechanical performance

A casting aluminum alloy and mechanics technology, applied in the field of casting aluminum alloy, can solve the problems of poor tensile strength and elongation casting performance, unsatisfactory comprehensive mechanical performance, high tensile strength, etc., to improve mechanical performance and comprehensive mechanical performance , the effect of improving the strength of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In this embodiment, the composition of the cast aluminum alloy with high mechanical properties in terms of mass percentage is:

[0016] Silicon: 7.5%, copper: 2.8%, magnesium: 0.4%, manganese: 0.4%, zirconium: 0.2%, molybdenum 0.5%, titanium: 0.15%, iron≤0.25%, and the balance is aluminum.

[0017] or as:

[0018] Silicon: 9.5%, copper: 4.2%, magnesium: 0.6%, manganese: 0.6%, zirconium: 0.4%, molybdenum 0.7%, titanium: 0.35%, iron≤0.25%, and the balance is aluminum.

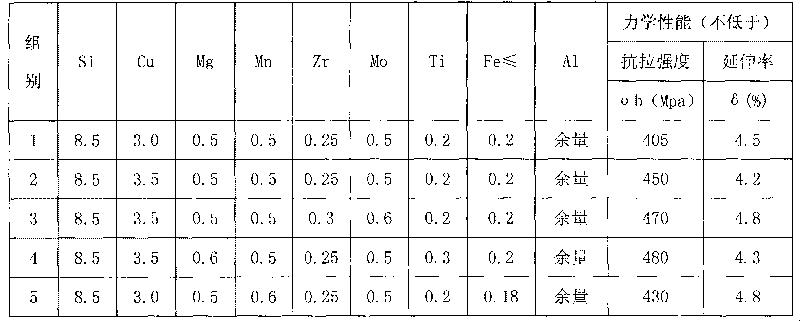

[0019] In specific implementation, various different compatibility forms (by mass percentage) can be obtained as listed in Table 1:

[0020]

[0021] The mechanical properties in the above table are the sampling values of the body, and the hardness values (HBS) are all greater than 120;

[0022] It can be seen from the above table: in group 1 and group 2, with the increase of copper content, the tensile strength increases and the elongation decreases;

[0023] It can be seen from group 3 and grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com