Electrolyte of electroplating palladium-nickel alloy

A technology of electrolyte and alloy, applied in the field of electrolyte, can solve problems such as no industrial application of palladium-nickel alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) The composition of the plating solution and the electroplating conditions are as follows

[0035] Palladium dichloride (calculated as palladium) 2g / L

[0036] Nickel sulfate hexahydrate 25g / L

[0037] Ammonium chloride 30~50g / L

[0038] Boric acid 40~50g / L

[0039] Ammonia 30~60ml / L

[0040] Sodium dodecylsulfonate 0.1~0.5g / L

[0041] Proynyl alcohol 0.05~0.4g / L

[0042] Saccharin 0.1~0.5g / L

[0043] pH (adjusted with ammonia water) 6.5~8

[0044] Current density 0.5~1A / dm 2

[0045] Temperature 45°C

[0046] Anode Platinized titanium mesh

[0047] The area ratio of cathode to anode is 1:2

[0048] Stir at medium speed during plating.

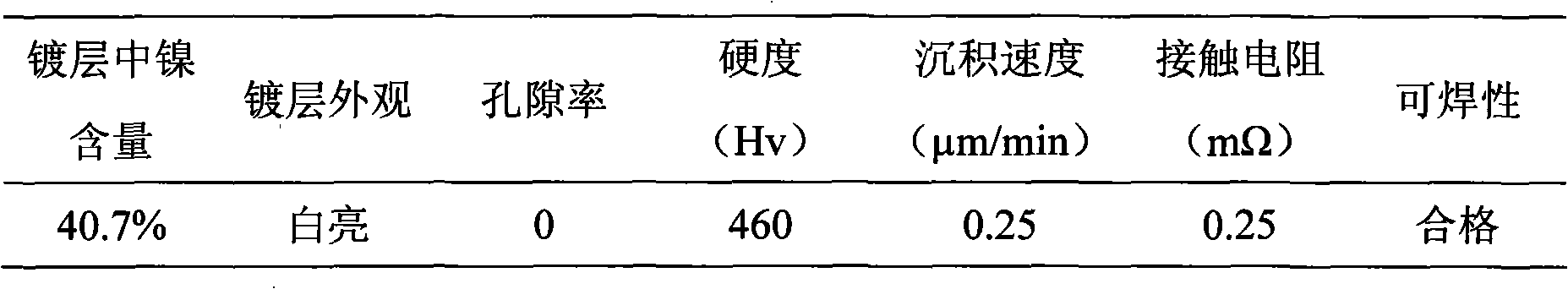

[0049] 2) Coating test results: see Table 1, contact resistance evaluation standard: SJ2431-84, the general gold coating contact resistance is less than 0.6mΩ.

[0050] Table 1

[0051]

Embodiment 2

[0053] 1) The composition of the plating solution and the electroplating conditions are as follows

[0054] Tetraammine palladium sulfate (calculated as palladium) 6g / L

[0055] Nickel chloride hexahydrate 25g / L

[0056] Sodium chloride 30~50g / L

[0057] Sodium pyroborate decahydrate 50~80g / L

[0058] Ethylenediamine 10~30g / L

[0059] Sodium dodecylsulfonate 0.1~0.5g / L

[0060] Niacin 0.05~0.4g / L

[0061] Sodium benzenesulfinate 0.05~0.5g / L

[0062] pH (adjusted with ammonia water) 6.5~7.5

[0063] Current density 1~1.5A / dm 2

[0064] Temperature 50°C

[0066] The area ratio of cathode to anode is 1:2

[0067] Stir at medium speed during plating.

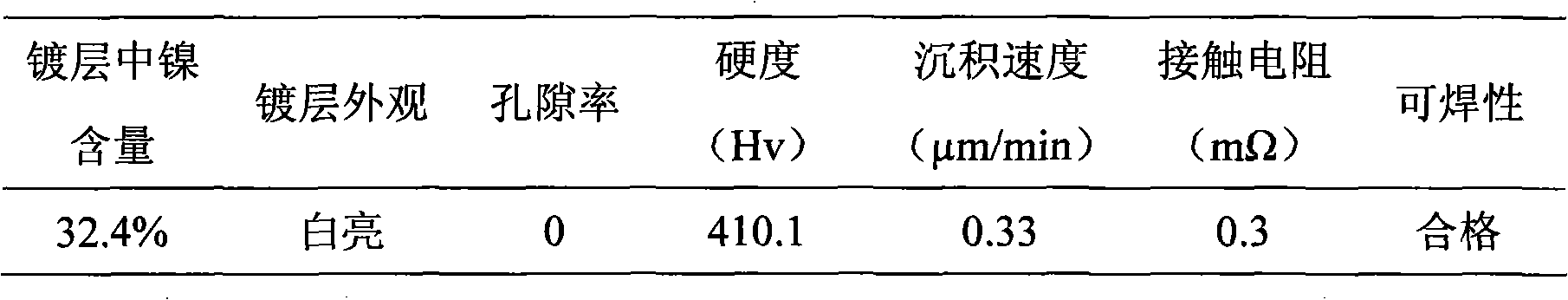

[0068] 2) Coating test results: see Table 2.

[0069] Table 2

[0070]

Embodiment 3

[0072] 1) The composition of the plating solution and the electroplating conditions are as follows

[0073] Ammonium palladium nitrite (as palladium) 8g / L

[0074] Nickel sulfamate 40g / L

[0075] Ammonium sulfate 30~60g / L

[0076] Boric acid 30~40g / L

[0077] Glycine 15~30g / L

[0078] Acrylamide 0.2~0.5g / L

[0079] Niacinamide 0.05~0.4g / L

[0080] Sodium dodecylsulfonate 0.05~0.5g / L

[0081] pH (adjusted with ammonia water) 7~9

[0082] Current density 1~1.5A / dm 2

[0083] Temperature 30°C

[0084] Anode stainless steel

[0085] The area ratio of cathode to anode is 1:3

[0086] Stir at medium speed during plating.

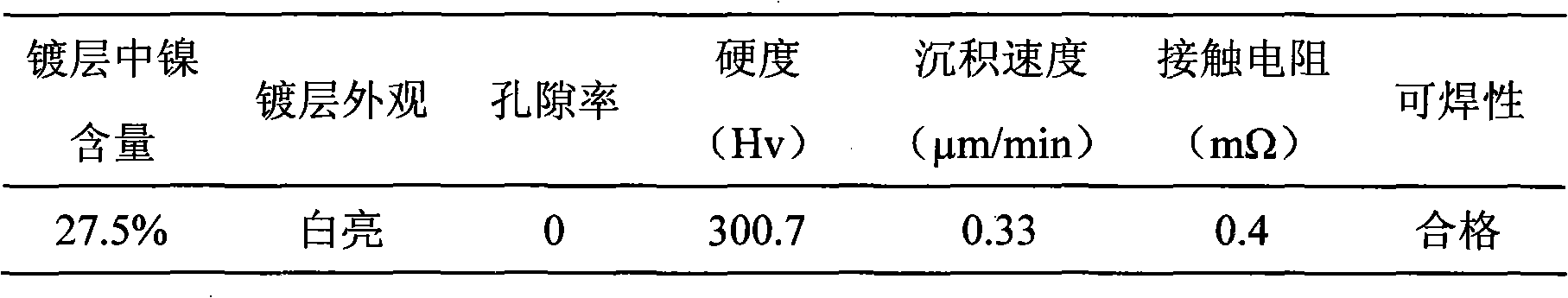

[0087] 2) Coating test results: see Table 3.

[0088] table 3

[0089]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com