Core-shell polynary lithium ion battery anode material distributed in all-concentration gradient way and preparation method thereof

A full concentration gradient, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems affecting material specific capacity, structural instability, safety performance, etc., to improve safety performance and cycle performance , the effect of high cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

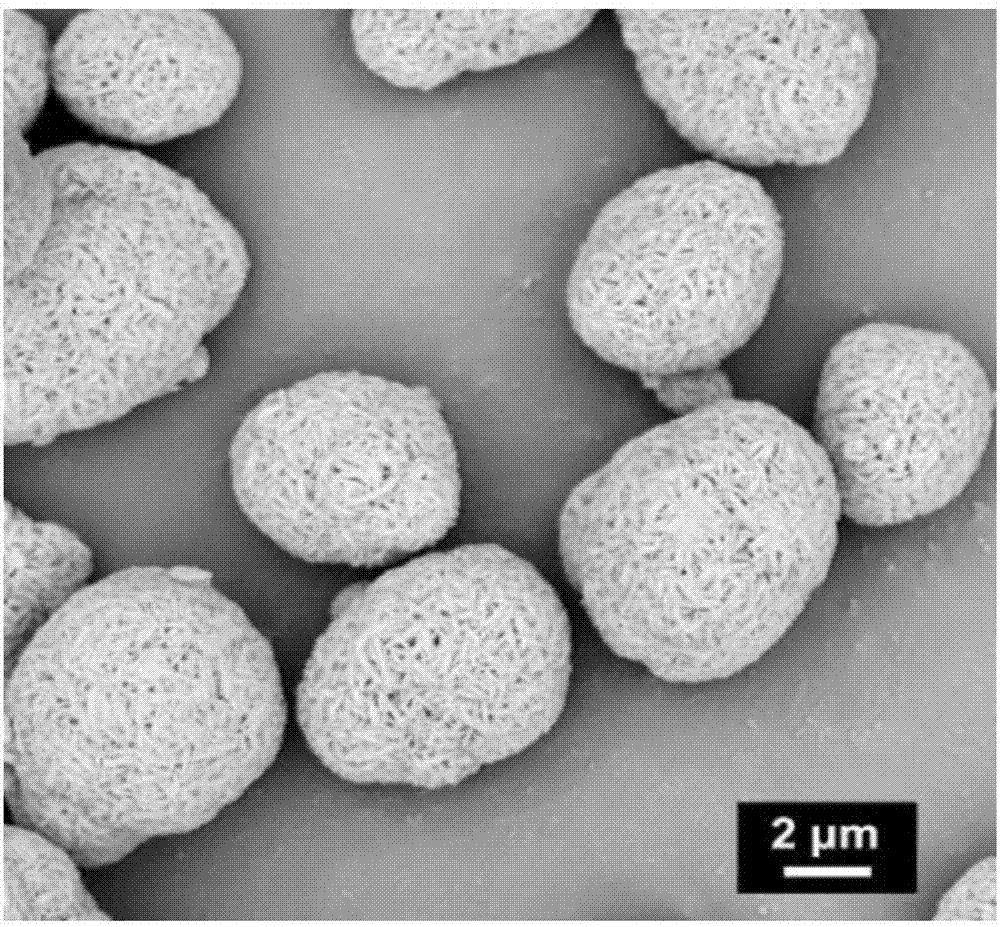

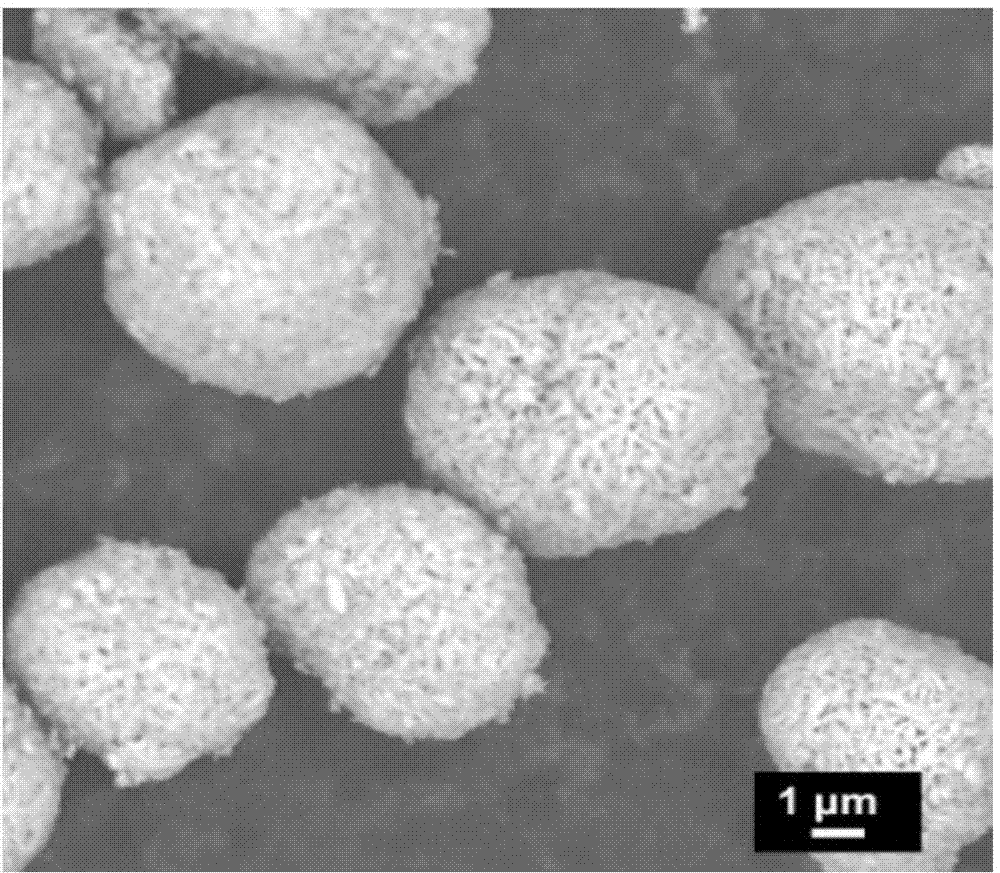

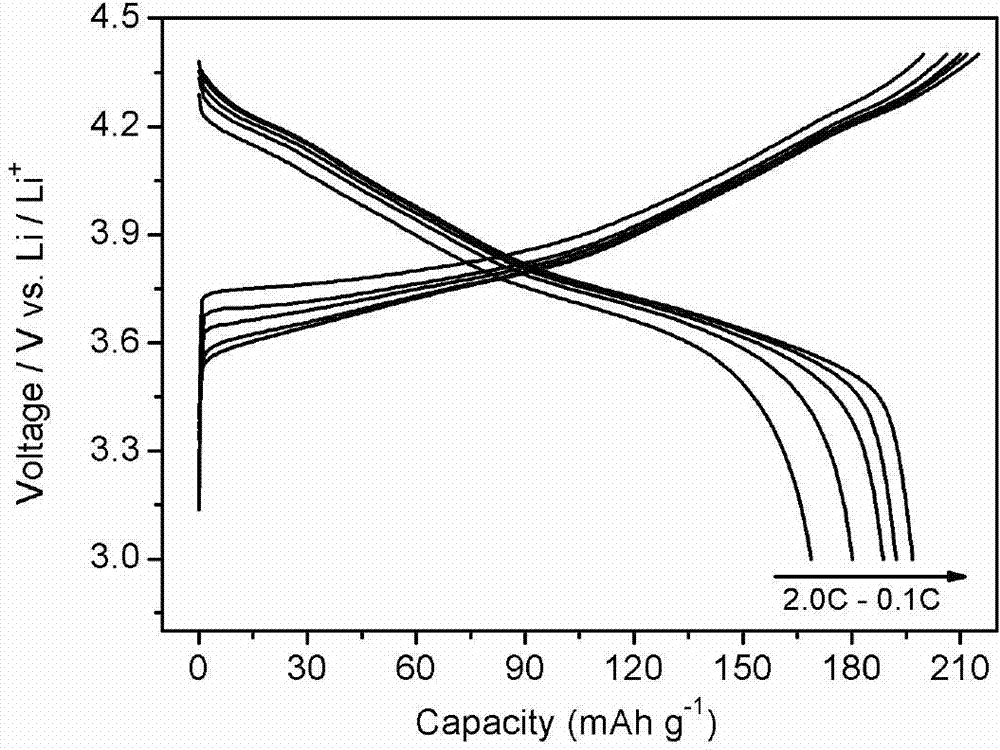

[0036] The raw materials used in this experiment are nickel sulfate, cobalt sulfate, and manganese sulfate as metal salts, sodium hydroxide as alkali solution, ammonia water as complexing agent, and lithium hydroxide as lithium source. First prepare solution A with a ratio of 0.9:0.05:0.05 of nickel, cobalt, and manganese with a total concentration of 2mol / L, solution B with an element ratio of 0.6:0.2:0.2, and an element ratio of 0.62:0.19:0.19 solution C, and prepare 4mol / L sodium carbonate solution and 10mol / L ammonia water at the same time, add the prepared solution B to solution A at a flow rate of 5L / h and mix well, mix well mixed solution A, hydrogen Sodium solution and ammonia water were added to the reaction kettle at the same time at a flow rate of 10L / h, the pH value was controlled at 8.0, the reaction temperature was 40°C, and the stirring speed was 300r / min. After the solution A was added dropwise, the flow rate was 5L / h Add the solution C into the reaction kettle...

Embodiment 2

[0041] The raw materials used in this experiment are nickel chloride, cobalt chloride, and manganese chloride as metal salts, lithium hydroxide as the alkali solution, ammonia water and disodium edetate as the complexing agent, and lithium carbonate as the lithium source. First prepare solution A with a ratio of 0.85:0.075:0.075 of nickel, cobalt and manganese with a total concentration of 2mol / L, solution B with an element ratio of 0.5:0.2:0.3, and an element ratio of 0.52:0.19:0.29 At the same time, prepare 4mol / L sodium hydroxide solution and 10mol / L ammonia water and disodium edetate solution, add the prepared solution B into solution A at a flow rate of 5L / h and mix well , Add the uniformly mixed solution A, sodium hydroxide solution, ammonia water and disodium ethylenediaminetetraacetic acid solution into the reaction kettle at the same time at a flow rate of 10L / h, control the pH value to 11.0, the reaction temperature is 60 ° C, the stirring speed The temperature is 12...

Embodiment 3

[0045] The raw materials used in this experiment are nickel sulfate, cobalt sulfate, and manganese sulfate as metal salts, sodium hydroxide as alkali solution, ammonia water as complexing agent, and lithium acetate as lithium source. First prepare solution A with a ratio of 0.85:0.075:0.075 of nickel, cobalt, and manganese with a total concentration of 3 mol / L, solution B with an element ratio of 0.6:0.2:0.2, and an element ratio of 0.62:0.19:0.19 solution C, prepare 8mol / L sodium hydroxide solution and 12mol / L ammonia water at the same time, add the prepared solution B into solution A at a flow rate of 120L / h and mix well, and mix uniformly solution A with 250L The flow rate of / h is added to the reaction kettle, and the sodium hydroxide solution and ammonia water are simultaneously added to the reaction kettle at a flow rate of 100L / h, and the pH value is controlled to be 10. The reaction temperature is 50°C and the stirring speed is 700r / min After solution A was added dropw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com