White-colored copper alloy with reduced nickel content

a technology of nickel content and white-colored copper, which is applied in the field of white-colored copperbased alloys, can solve the problems of difficult to achieve good white colors without strong, nickel is more expensive than most other alloying elements, and alloys are expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

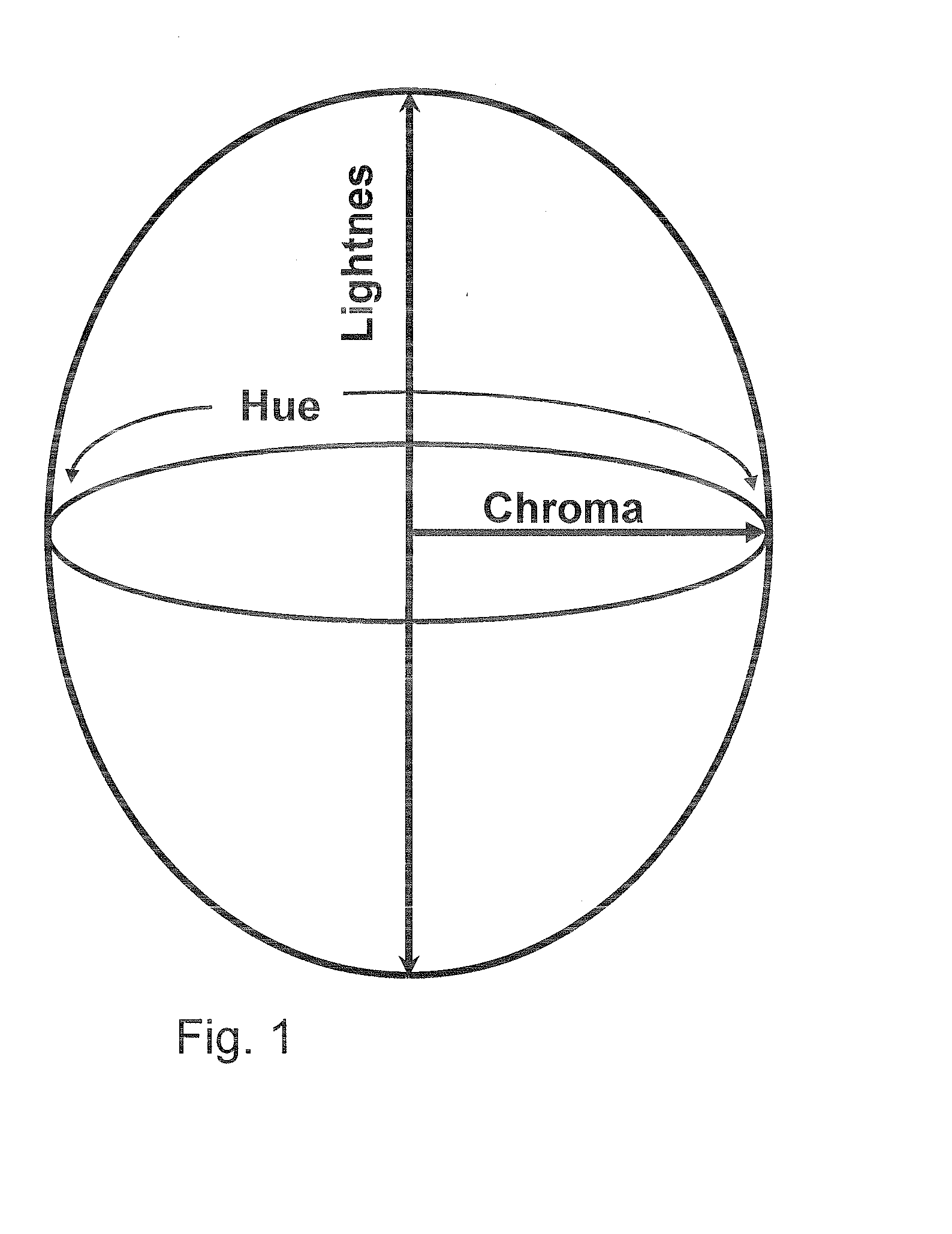

[0039]Determination of color (of alloys or other materials) may be by spectroscopy or other objective means. Instruments such as those supplied by X-Rite, Inc. (Grand Rapids, Mich.) or Hunter Associates Laboratory, Inc. (Reston, Va.) quantify color according to two chromatic attributes “hue” and “chroma” and a lightness attribute known as “value”. Hue is color perception, the recognition of an object as red, green, yellow, blue, etc. Chroma is the color concentration (intensity or saturation), ranging from gray to the pure hue. Value is a measure of the lightness of the color tone, ranging from pure white to pure black. A combination of these values gives a unique location in color space in polar coordinates, with hue denoting color tone (angular location), chroma denoting intensity (radial location), and value denoting lightness (vertical location) in FIG. 1.

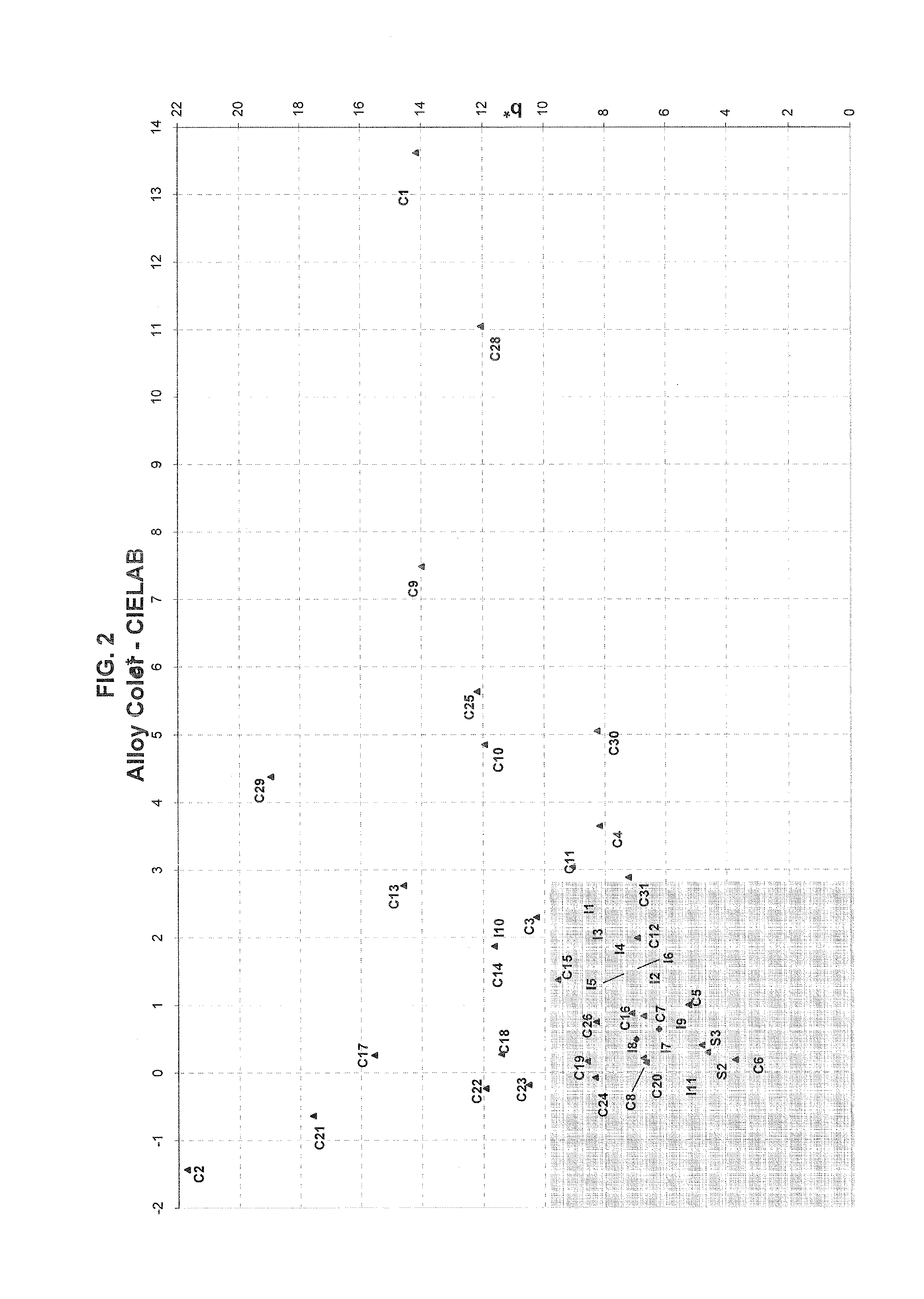

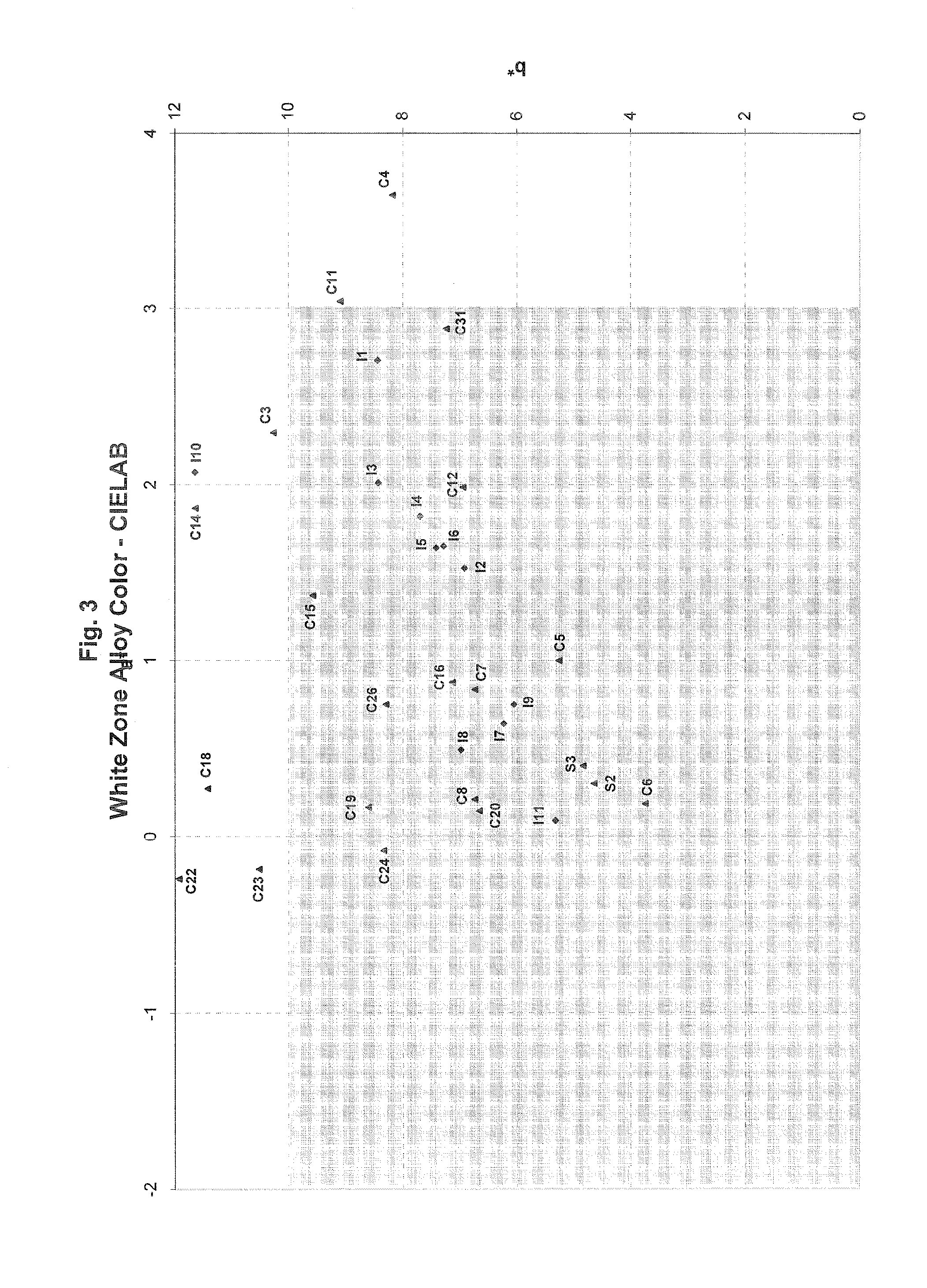

[0040]An alternative method of specifying color is by the CIELAB scale. CIE stands for Commission Internationale de l'Eclaira...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com