Copper current collector surface nanocrystallization method

A current collector and nanotechnology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of active material pulverization, failure, volume change, etc., and achieve electrochemical performance improvement, The method is simple and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

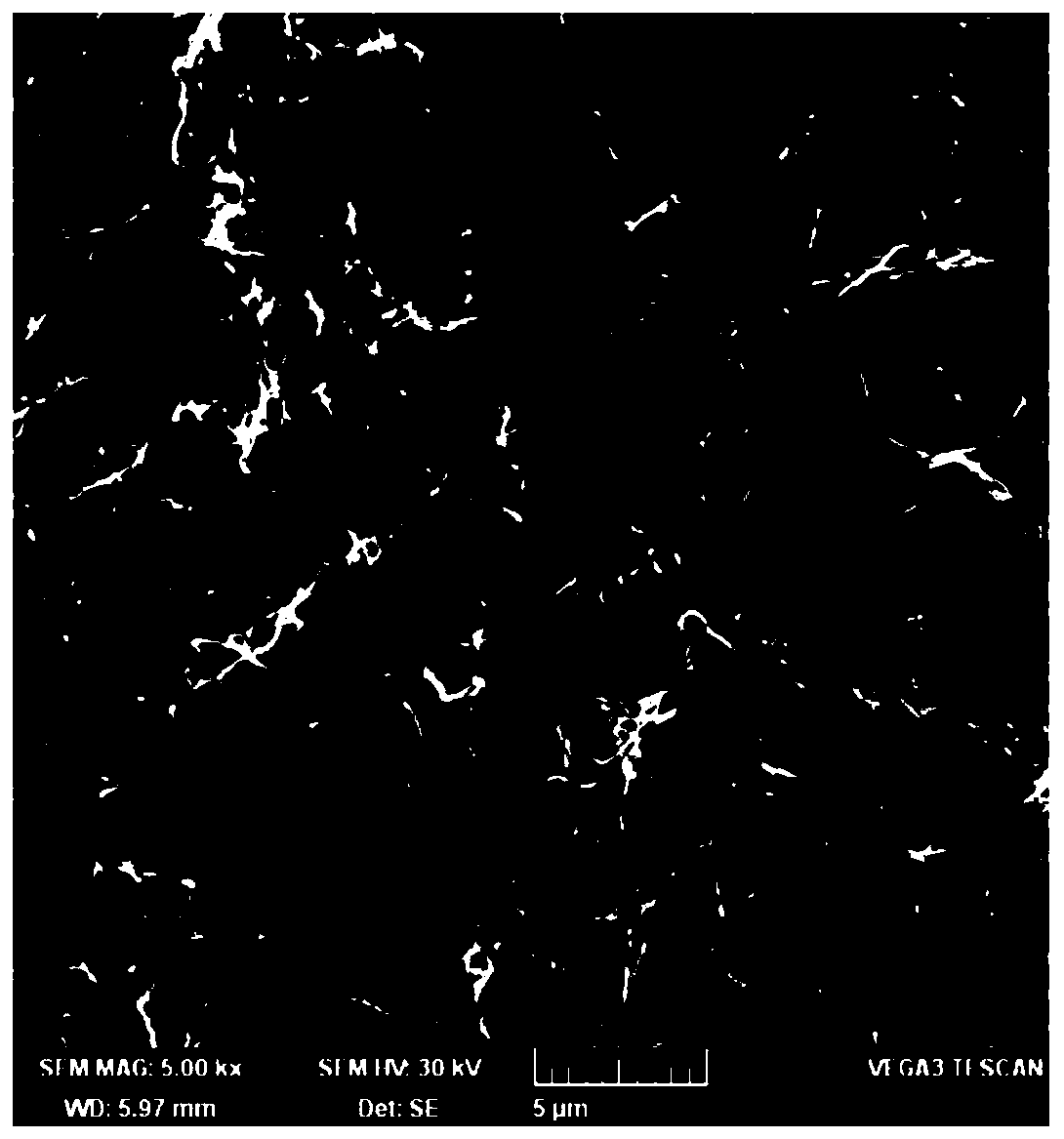

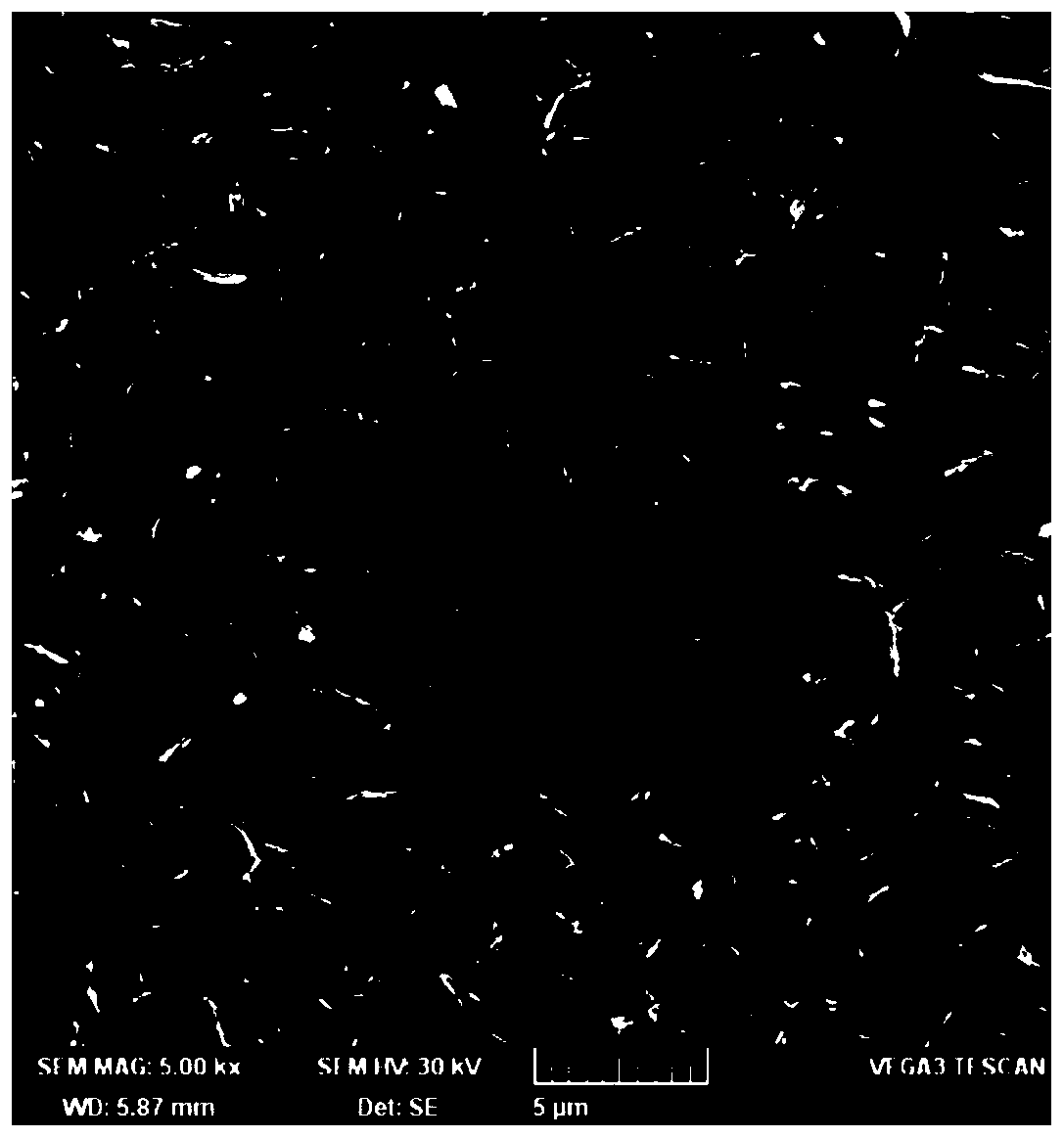

[0039] A method for surface nanometerization of a copper current collector, said method comprising the following steps:

[0040] 1) Alkaline solution is configured, the pretreated copper substrate is placed in the alkaline solution for erosion treatment, and after the erosion is completed, it is dried to obtain a pre-substrate;

[0041] 2) The pre-matrix is used as a working electrode, platinum or graphite is used as a counter electrode, and a saturated calomel electrode is used as a reference electrode, and the pre-matrix is reduced by a three-electrode system in the electrolyte to form a porous template;

[0042] 3) Prepare an electrodeposition solution containing active metal ions, use a porous template as a working electrode, platinum or graphite as a counter electrode, and a saturated calomel electrode as a reference electrode, and place it in the electrodeposition solution using a three-electrode system in the pores of the porous template. Deposit active metal oxides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com