NbTaMoWNx nitride coating with high-temperature diffusion shielding performance and preparation method thereof

A technology of shielding performance and high temperature diffusion, which is applied in the field of microelectronic materials, can solve the problems of electrical performance degradation and other problems, and achieve the effects of short time consumption, good thermal stability and good diffusion shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

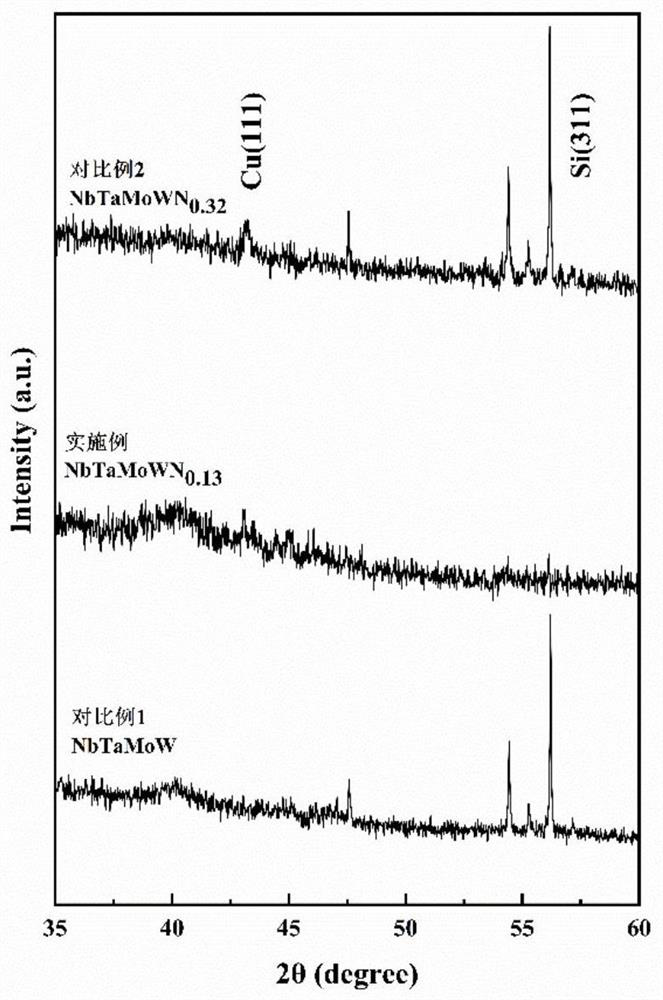

[0020] (1) Using DC magnetron sputtering method, in Ar and N 2 Under the atmosphere, the NbTaMoW high-entropy alloy target is used to sputter on the Si single-throw wafer to obtain the coating. The specific process parameters of DC magnetron sputtering are: target base distance 8cm, vacuum degree of sputtering chamber lower than 4.3×10 -3 Pa, the working pressure is 0.3Pa, the Ar flow is 38sccm, N 2 The flow rate is 2sccm, the sputtering power is 100W, and the sputtering time is controlled to be 8min to prepare NbTaMoWN 0.13 .

[0021] (2) Using the method of direct current magnetron sputtering, the copper conductive layer is covered on the coating prepared in step (1). The specific process parameters are: the target base distance is 8cm, the vacuum degree of the sputtering chamber is lower than 4.3×10 -3 Pa, the working pressure is 0.3Pa, the Ar flow rate is 40sccm, the sputtering power is 60W, and the sputtering time is controlled as 4min.

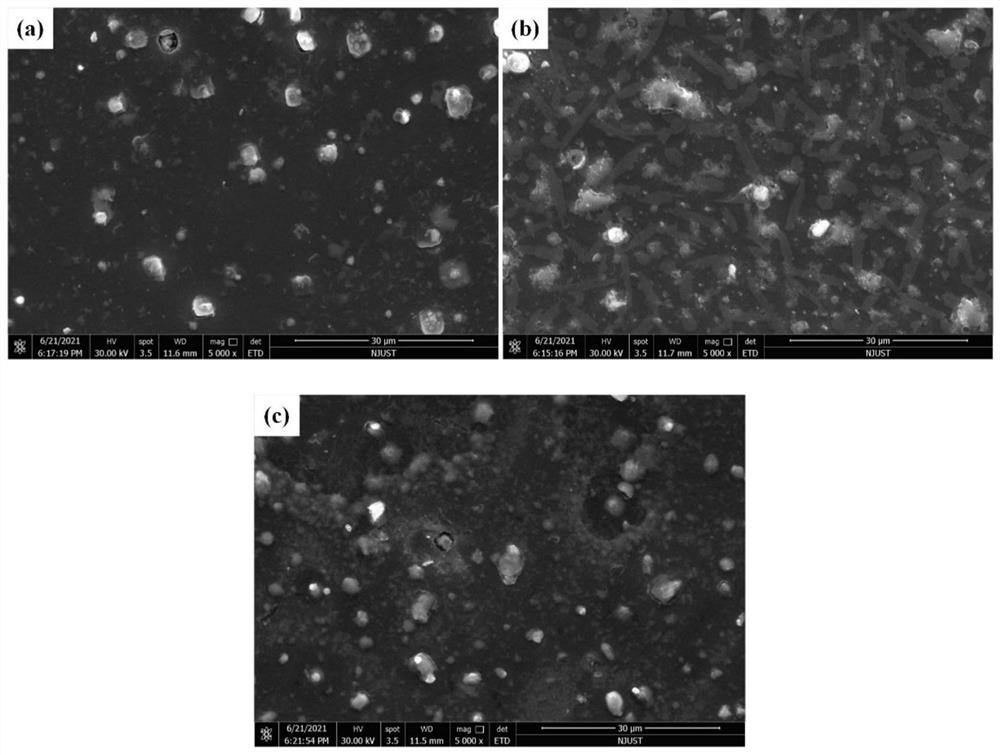

[0022] (3) Annealing test: A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com