Non-woven fabric composite self-lubricating gasket with gradient distribution in thickness direction

A gradient distribution, non-woven fabric technology, applied in the direction of layered products, synthetic resin layered products, metal layered products, etc., can solve the anisotropy of tension and compression properties, changes in the mechanical properties of the contact surface, and easy fiber breakage To achieve the effect of improving comprehensive mechanical properties, good self-lubricating properties, and convenient adjustment and reinforcement of component materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

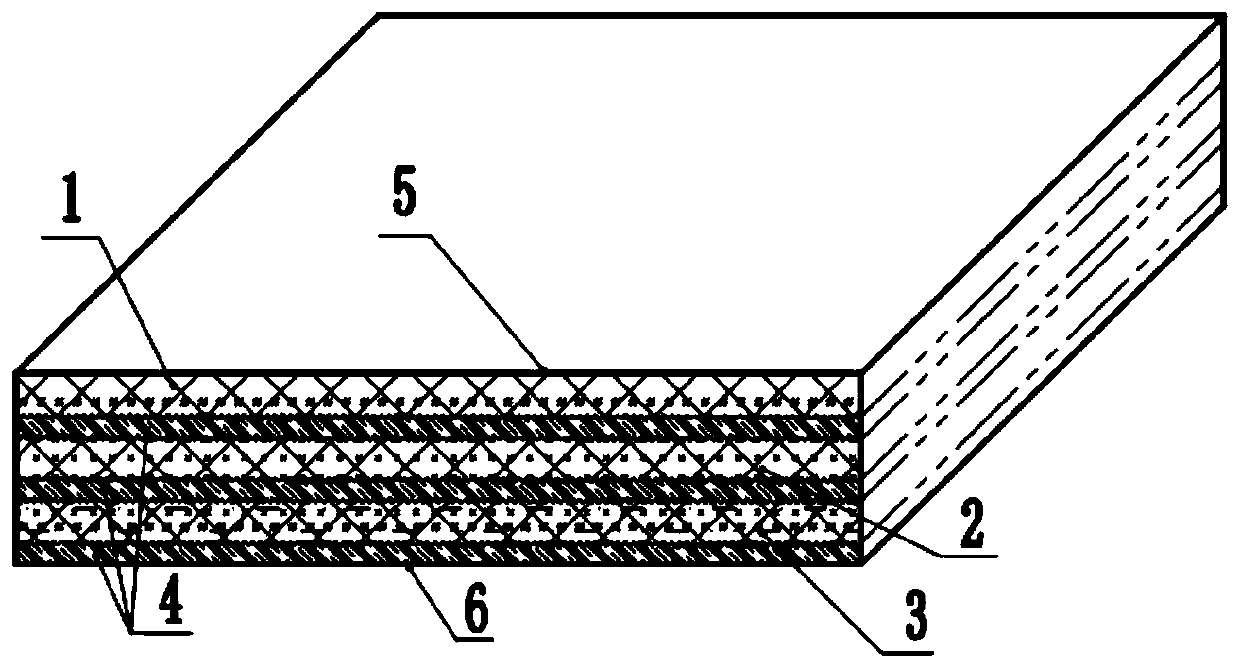

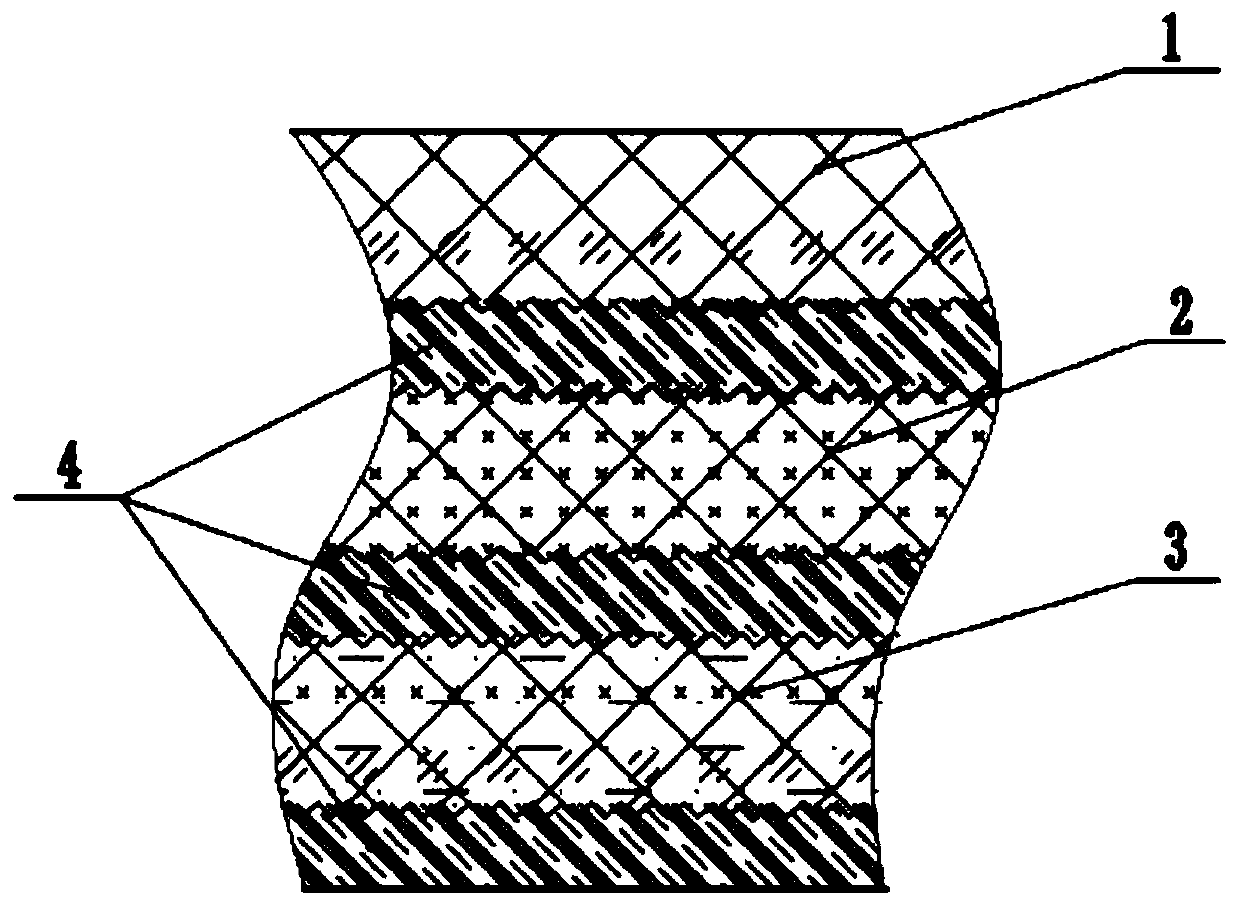

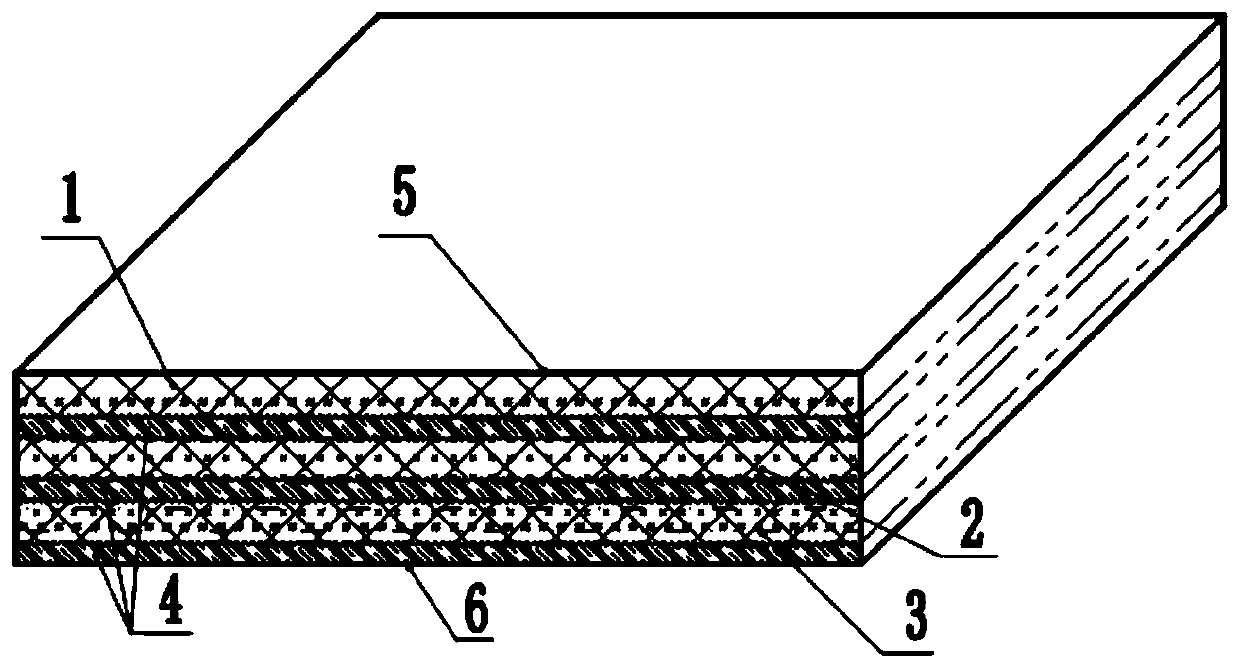

[0021] Such as figure 1 As shown, the embodiment of the present invention proposes a non-woven composite self-lubricating liner with a gradient distribution in the thickness direction, including three layers of fiber non-woven fabrics, wherein the three layers of fiber non-woven fabrics are respectively the working layer 1, the reinforcement Layer 2 and paste layer 3 are bonded sequentially by thermosetting resin glue 4 layers, figure 2 is a partial view of the section of the liner in the thickness direction of the embodiment of the present invention.

[0022] In this embodiment, the working layer 1 is composed of PTFE fibers with a volume content of 75% and reinforcing fibers with a volume content of 25%.

[0023] The reinforcing layer 2 is composed of PTFE fibers with a volume content of 25% and reinforcing fibers with a volume content of 75%.

[0024] The adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com