Abrasion-resistant and corrosion-resistant concrete and preparation method thereof

A corrosion-resistant concrete and anti-abrasion technology, applied in the field of building materials, can solve the problems of poor anti-sea wave resistance to chloride ion erosion, insufficient concrete surface hardness, endangering the normal operation of buildings, etc., so as to increase durability and prevent The effect of diffusion and improvement of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

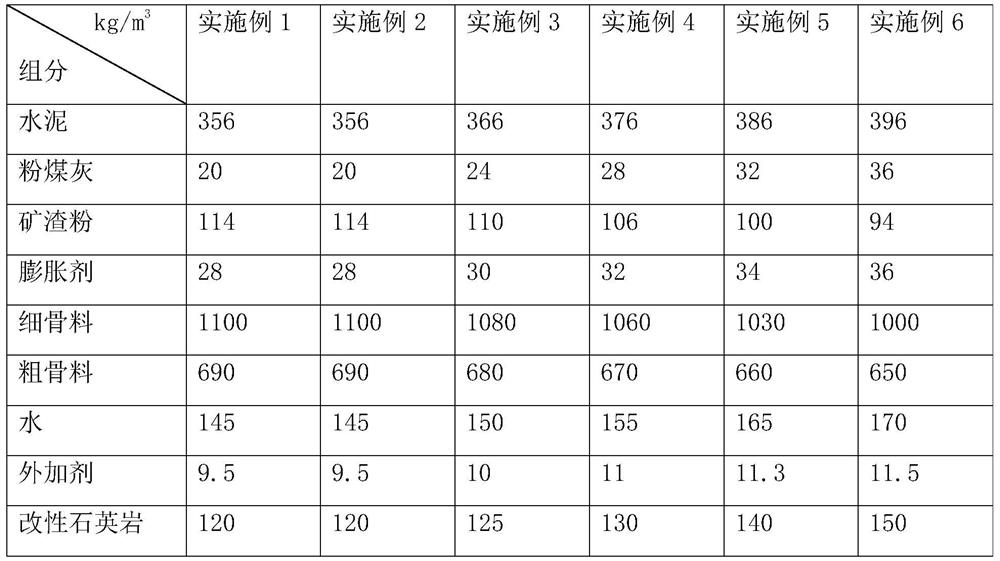

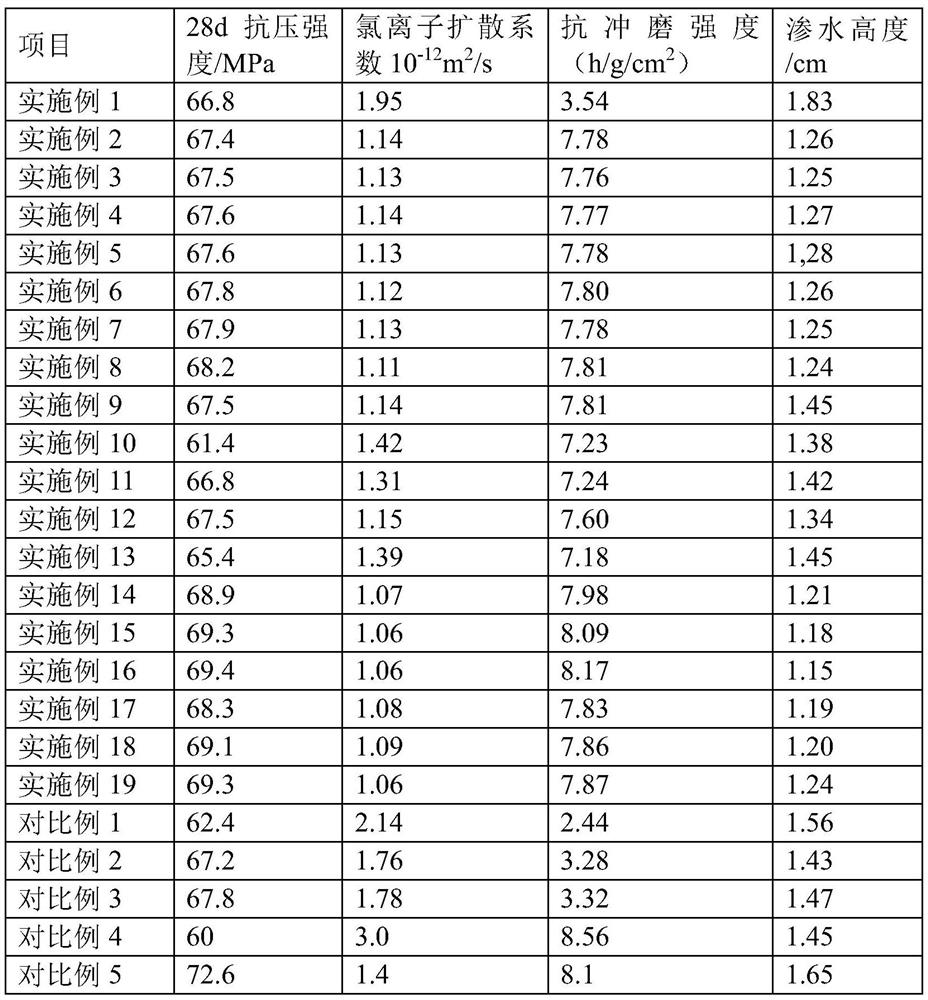

Examples

preparation example 1-8

[0039] In Preparation Example 1-8, the silane coupling agent KH-550 is selected from Qingdao Xuxin Chemical Co., Ltd., the rice husk ash is selected from Lingshou County Caiyu Mineral Powder Factory, the article number is DK12251950, and the methyltriethoxysilane is selected from Beijing Jintong Letai Chemical Products Co., Ltd., hydroxy silicone oil is selected from Jinan Benyuan Chemical Co., Ltd., the model is PMX-200, and the graphene oxide model is selected from Hunan Fenghua Material Development Co., Ltd., FH-661, lotus leaf hydrophobic The agent is selected from Shanghai Kaiyin Chemical Co., Ltd., the model is P800, the aramid fiber is selected from Shenzhen Teli New Material Technology Co., Ltd., the model is TL001, and the carbon fiber is selected from Yixing Siqi Carbon Fiber Products Co., Ltd., the product number is 200. The polypropylene fiber was selected from Renqiu Jinyu Chemical Co., Ltd., the product number is 08, and the PTFE emulsion was selected from Guangzh...

preparation example 1

[0040] Preparation Example 1: (1) Dried and crushed 4kg of coal gangue to 10mm, added 0.5kg of silane coupling agent KH-550 dissolved in 5kg of ethanol, stirred evenly at room temperature, added 1kg with a density of 2.20g / cm 3 The rice husk ash is mixed evenly, and the rice husk ash is adjusted to pH value to 4 with sulfuric acid in advance, and then it is 0.25% ethylene glycol grinding 60min with 1kg concentration, and its chemical composition is as shown in table 1; (2) 0.8kg The hydrophobic agent is dissolved in 2kg of ethanol solution, sprayed and deposited on the rice husk ash and coal gangue, aged at 80°C for 24 hours, added with 2kg of composite fibers, and mixed evenly to obtain an anti-wear and anti-corrosion additive. The hydrophobic agent is made of It is made by mixing methyltriethoxysilane, hydroxyl silicone oil and graphene oxide with a mass ratio of 1:0.3:0.2. The composite fiber is made of aramid fiber, carbon fiber and polypropylene fiber mixed evenly and soak...

preparation example 2

[0043] Preparation example 2: (1) Dry and crush 7kg of coal gangue to 10mm, add 0.8kg of silane coupling agent KH-550 dissolved in 6kg of ethanol, stir evenly at room temperature, add 1.5kg of 3 The rice husk ash of rice husk is mixed evenly, and the rice husk ash is adjusted pH value to 4 with sulfuric acid in advance, and then is 0.25% ethylene glycol grinding 60min with 1kg concentration, and its chemical composition is as shown in table 1; (2) 1.0 Dissolve 2.5 kg of hydrophobic agent in 2.5 kg of ethanol solution, atomize and deposit on rice husk ash and coal gangue, place it at 85°C for 22 hours, add 3.5 kg of composite fiber, and mix evenly to obtain an anti-wear and anti-corrosion additive. Hydrophobic agent is made by mixing methyltriethoxysilane, hydroxyl silicone oil and graphene oxide with the ratio of 1:0.4:0.3, and the composite fiber is made by mixing evenly aramid fiber, carbon fiber and polypropylene fiber and soaking in PTFE emulsion , the mass ratio of aramid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com