Lithium-sulphur battery anode material and preparation method thereof

A cathode material, sulfur battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of rapid capacity decay, low utilization rate of active materials, low specific capacity of sulfur electrodes, etc., and achieve the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

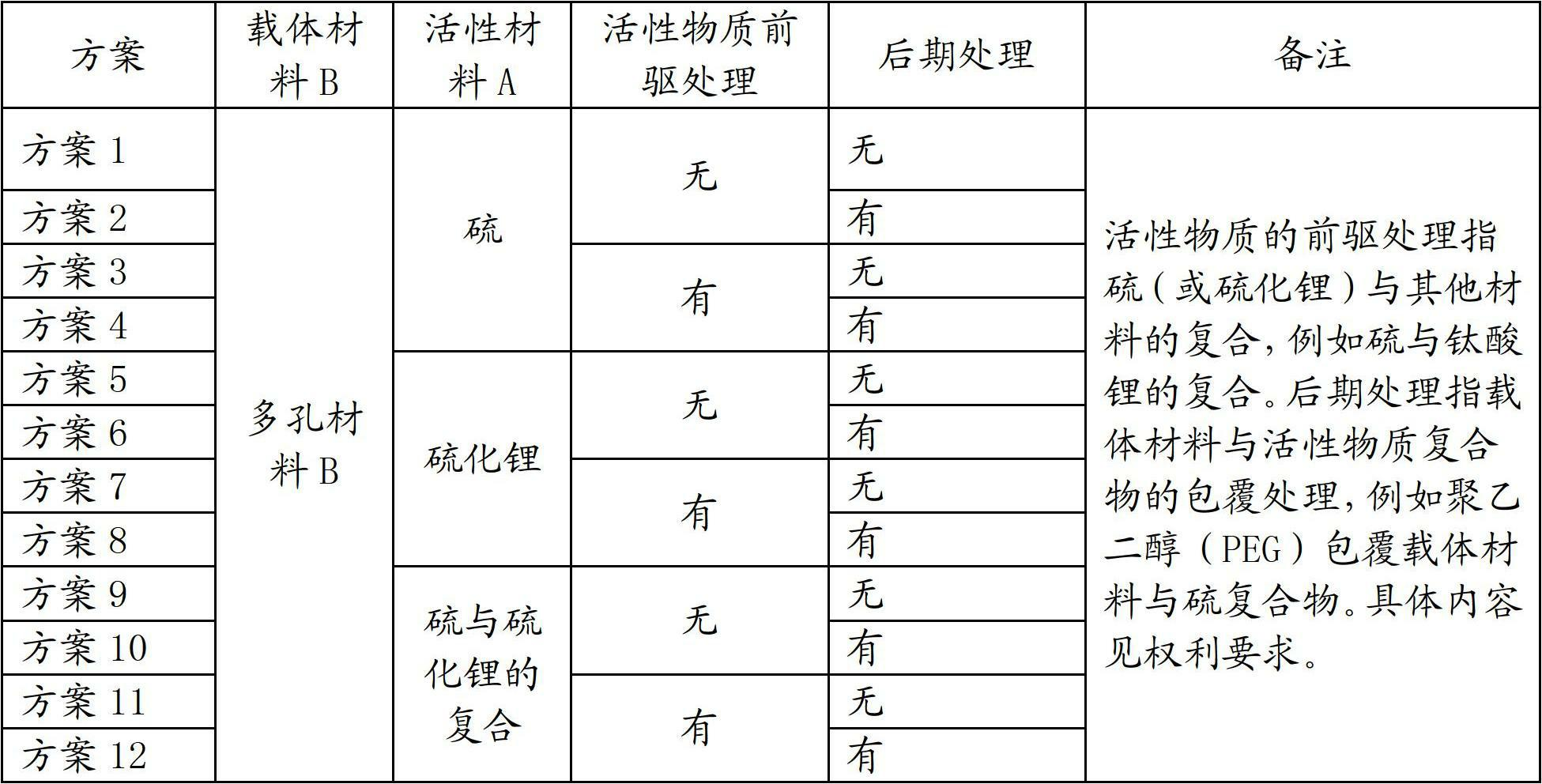

Embodiment 1-84

[0031] The carrier material is lithium titanate (Li 4 Ti 5 o 12 ), the negative plate is made of metal lithium, and the electrolyte is 1mol / L bis-three mixed organic solvent 1,3-dioxolane (DOL): ethylene glycol dimethyl ether (DME) = 1:1 (v:v) Lithium fluoromethanesulfonate imide (LiTFSI) solution.

Embodiment 1

[0033] A lithium-sulfur battery positive electrode material, the specific process of adopting scheme 1 is as follows:

[0034] Li 4 Ti 5 o 12 The preparation process of the composite material with elemental sulfur is as follows: Li 4 Ti 5 o 12 Mix with elemental sulfur at a weight ratio of 1:5, press into tablets, place in a tube furnace, pass argon, and treat at 155°C for 12 hours, and then at 300°C for 2 hours.

[0035] Weigh a certain amount of Li according to the weight percentage 80:15:5 4 Ti 5 o 12 Composite with elemental sulfur, acetylene black and polytetrafluoroethylene (PTFE), ground, rolled out, pressed onto an aluminum mesh, and subsequently dried.

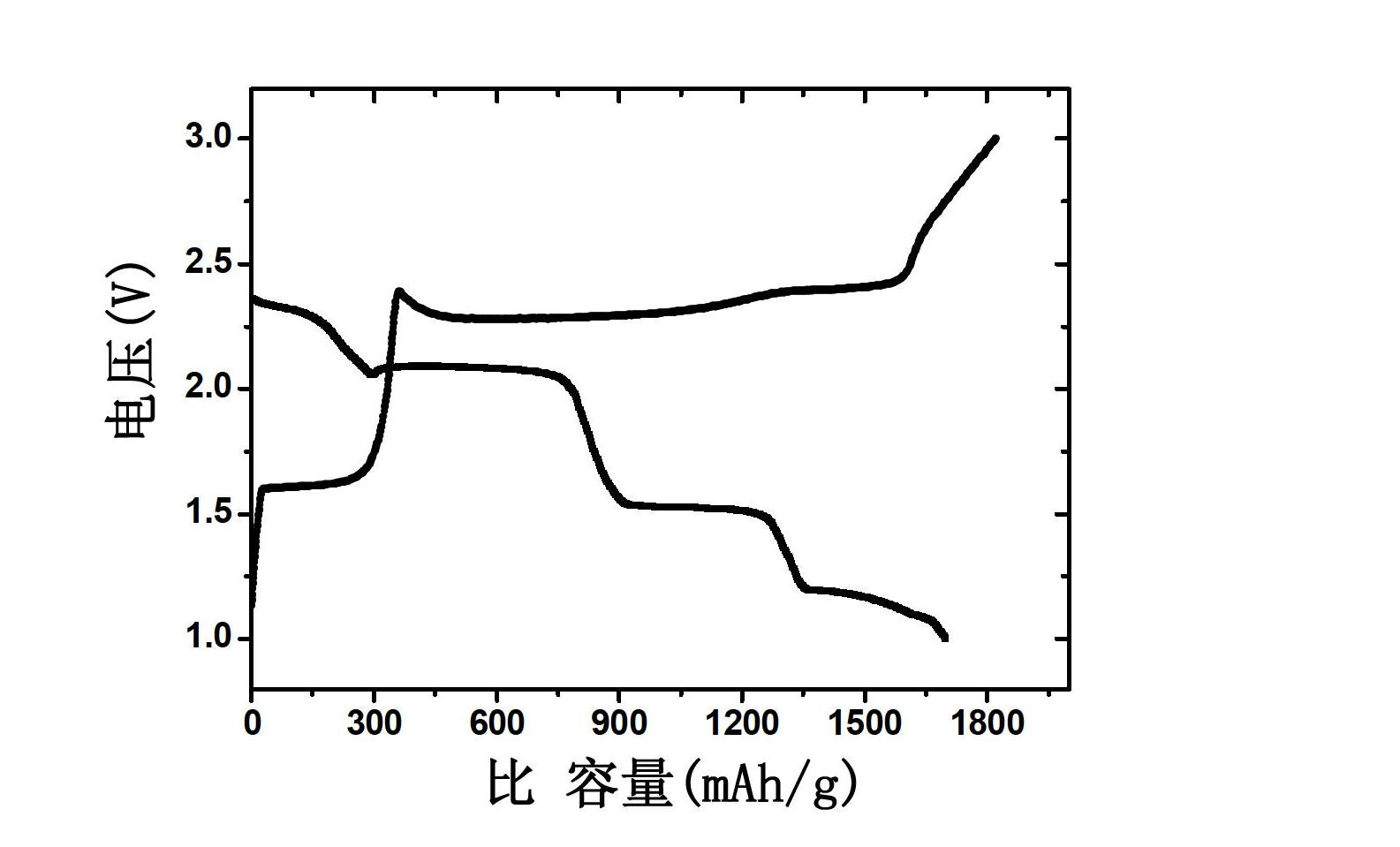

[0036] The charge and discharge curve of the battery in the first week is as follows: figure 1 shown. from figure 1 It can be seen that the discharge specific capacity of the battery in the first week is 1698mAh / g, and the charge specific capacity is 1822mAh / g.

Embodiment 2

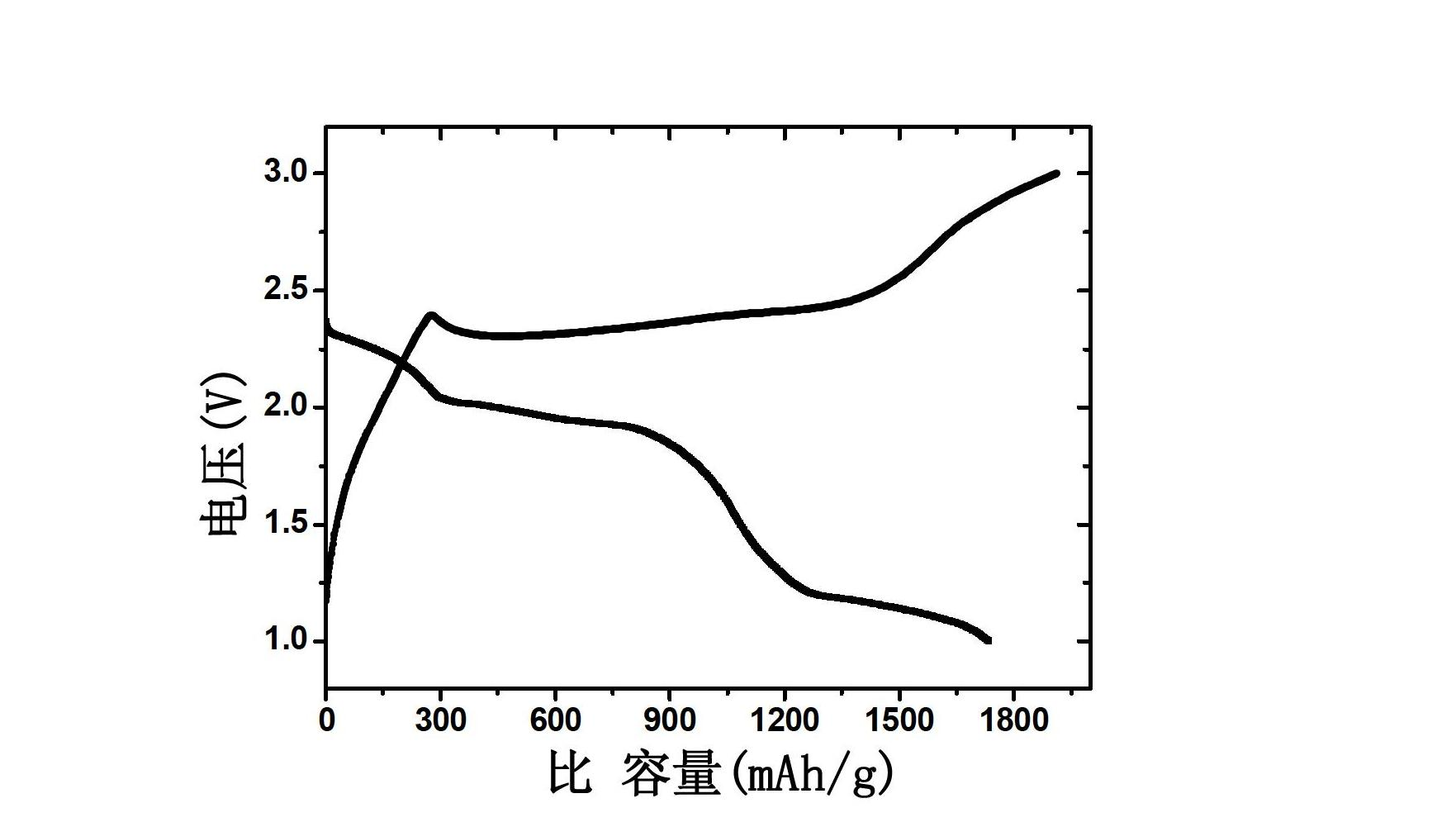

[0038] A lithium-sulfur battery positive electrode material, the specific process of adopting scheme 2 is as follows:

[0039] Li 4 Ti 5 o 12 The preparation process of the composite material with elemental sulfur is as follows: Li 4 Ti 5 o 12 Mix with elemental sulfur at a weight ratio of 1:3, press into tablets, put in a tube furnace, pass argon, and treat at 155°C for 12 hours.

[0040] Will Li 4 Ti 5 o 12 Soak the composite material with elemental sulfur in triton (polyethylene glycol p-isooctylphenyl ether) solution for 2 hours, take it out, and dry it in vacuum to obtain polyethylene glycol (PEG)-coated Li 4 Ti 5 o 12 Composite with elemental sulfur.

[0041] Weigh Li respectively according to weight percentage 80:15:5 4 Ti 5 o 12 Composite with elemental sulfur, acetylene black and polytetrafluoroethylene (PTFE), ground, rolled out, pressed onto an aluminum mesh, and subsequently dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity in the first week | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Discharge specific capacity in the first week | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com