Resin isobaric liquid-phase impregnation densification method for rapidly filling pores inside carbon/carbon composite material

A carbon composite material, liquid phase impregnation technology, applied in the field of composite material densification treatment, can solve the problems of limiting the popularization and application of carbon/carbon composite materials, high manufacturing cost, hindering large-scale application, etc., to reduce the number of cycles and The effect of large pore residual amount, shortening production cycle and improving densification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Three carbon / carbon crucibles for Czochralski monocrystalline silicon were produced by resin isobaric liquid phase impregnation (PIP) densification method, and the size of the crucible was Φ500×450mm. Technical indicators require bulk density ≥ 1.65g / cm 3 .

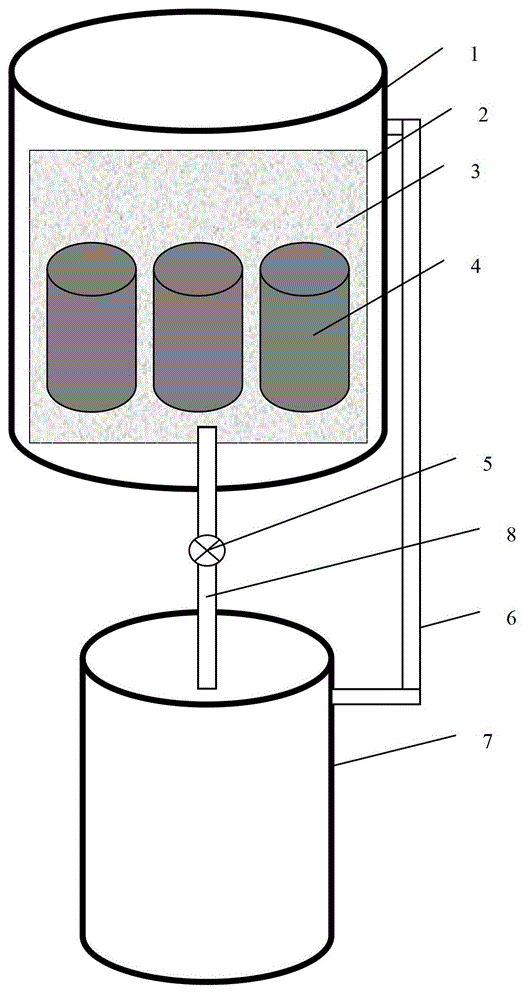

[0042] The resin PIP process includes the use of a vacuum autoclave with an isobaric recovery device for the impregnating liquid (structure such as figure 1 shown), the equal-pressure recovery device is a pressure-bearing recovery tank 6 located outside the vacuum autoclave 1, which communicates with the bottom of the impregnation cylinder 2 built in the vacuum autoclave 1 through pipelines and valves 5, and passes through the pressure-bearing Vent pipe 7 is communicated with vacuum autoclave 1, and vacuum autoclave 1 and pressure-bearing recovery tank 6 maintain gas ventilation and equal pressure; the steps are as follows:

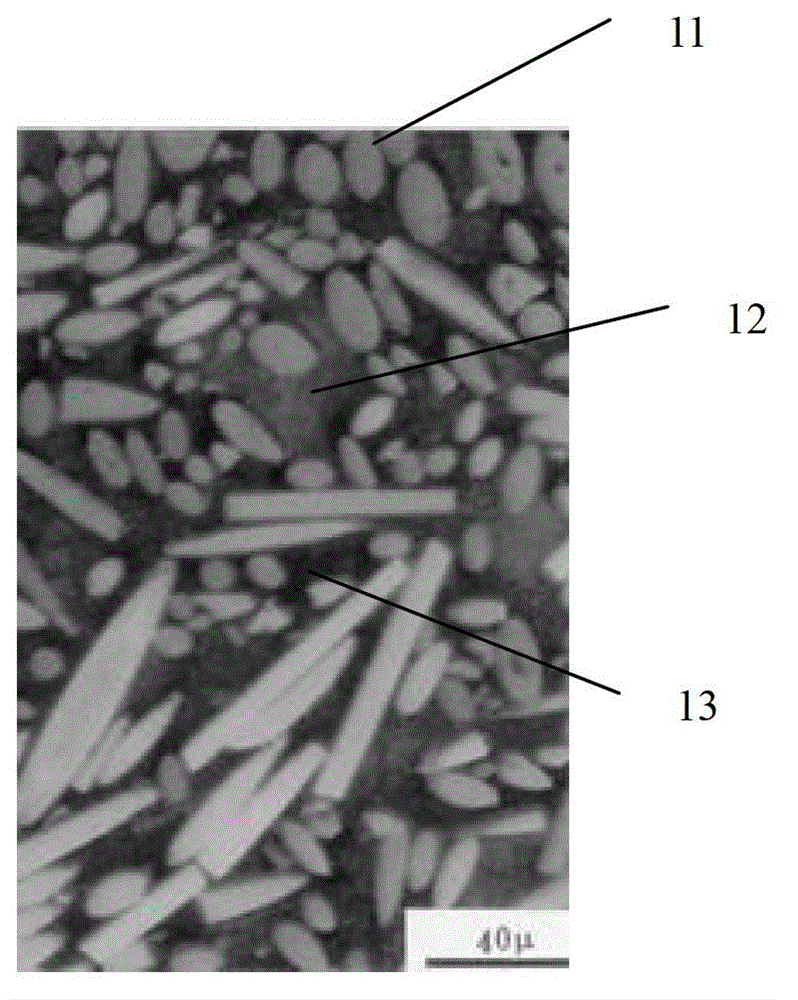

[0043] First, put 3 carbon fiber prefabricated crucibles (carbon / carbon crucible prefabr...

Embodiment 2

[0048] Produce 3 carbon / carbon crucibles for smelting and purifying polysilicon, crucible size: Φ600×600mm. Technical indicators require bulk density ≥ 1.55g / cm 3 .

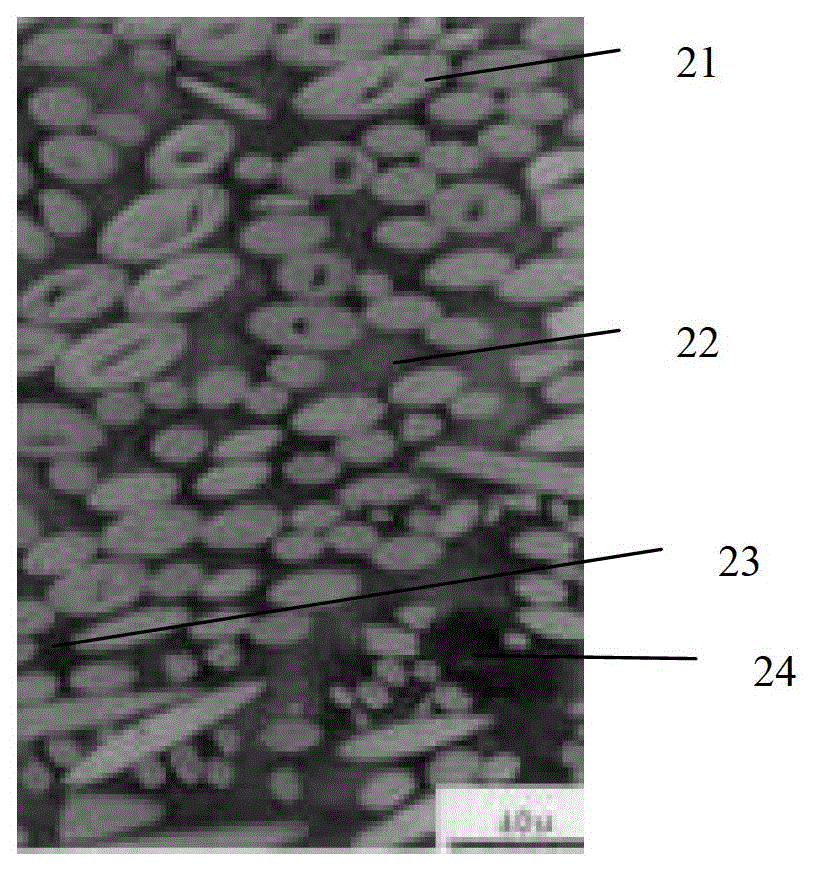

[0049] First, put 3 carbon fiber prefabricated crucibles in the impregnation cylinder of the vacuum autoclave, heat up and evacuate, when the temperature reaches 80°C, under the condition of vacuum degree of 1000±100Pa, keep the temperature for 60min, keep the vacuum degree and temperature conditions, put Prepare a preheated 120°C benzoxazine resin as the impregnating solution, and pour it into the impregnation cylinder; then, fill it with pure nitrogen to 4.0±0.1MPa, keep it at constant pressure for 60 minutes; Immersion solution; then, continue to heat up under constant pressure, when the temperature is 240±10°C, keep it warm for 60 minutes; then, release the gas to normal pressure, open the tank cover, take out the workpiece and place it in the working chamber of the carbonization furnace, replace the air wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com