Variable frequency ultrasonic semi-continuous casting method for magnesium alloy

A frequency conversion ultrasonic and magnesium alloy technology, applied in the field of light alloy processing, can solve the problems of limited ultrasonic field action range, unfavorable production of large-diameter ingots, change of melt resonant frequency, etc. The effect of resonance and mechanical properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

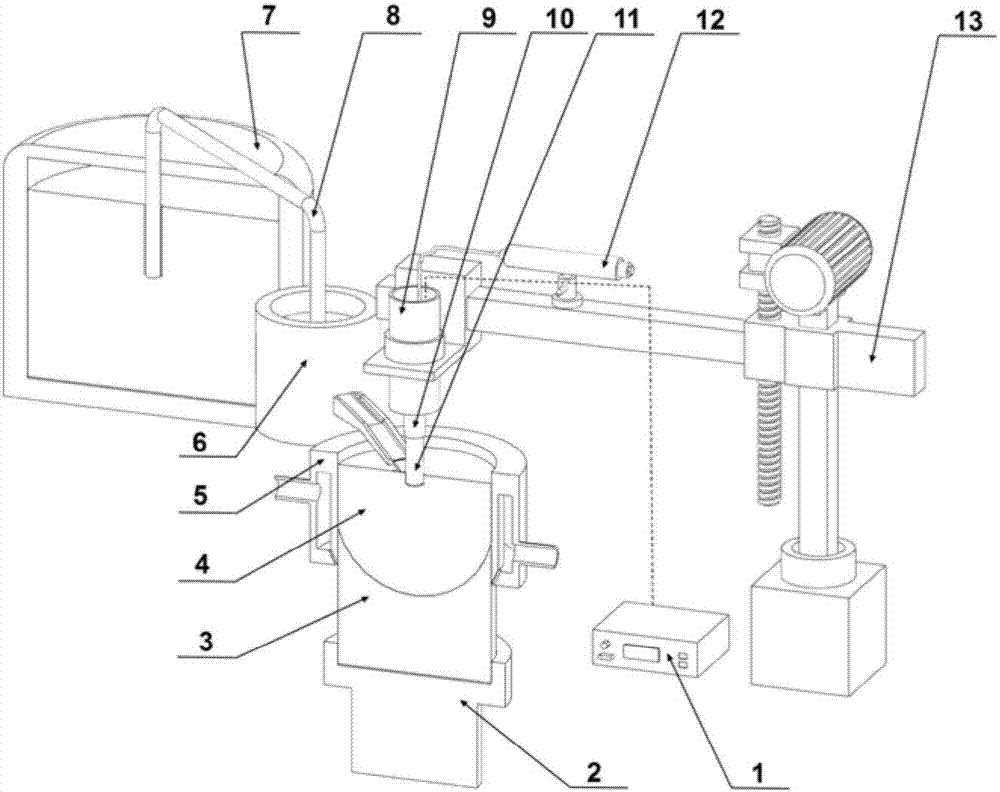

[0063] Embodiment 1: ZK60 magnesium alloy Ingot frequency conversion ultrasonic semi-continuous casting

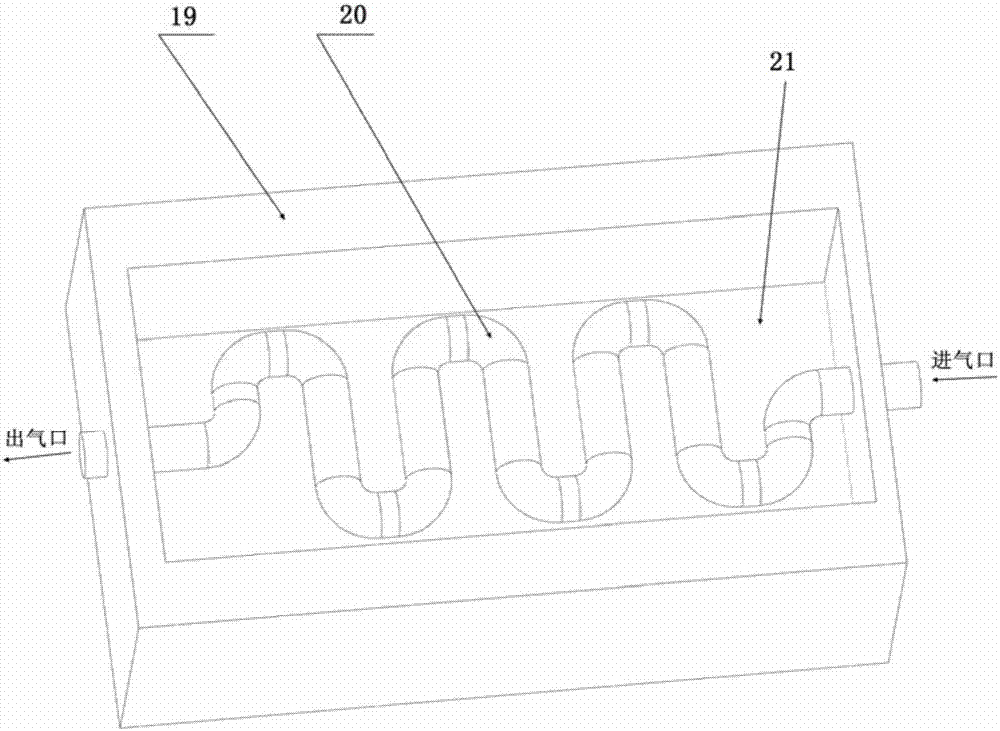

[0064]In this embodiment, each ingredient is melted and refined in an alloy melting furnace according to the ratio of the ZK60 magnesium alloy; casting starts when the temperature of the tundish is 660°C, and an ultrasonic radiation rod is inserted below the liquid surface of the melt during the casting process. The melt is subjected to continuous frequency conversion ultrasonic treatment, and the compressed air in the frequency conversion ultrasonic system is cooled by piezoelectric ultrasonic transducers and eddy current cooling tubes.

[0065] Casting process conditions: casting speed 50mm / min; The 304 stainless steel ultrasonic radiation rod is baked with acetylene to 600°C; the set ultrasonic basic frequency is 21kHz, the frequency change rate is 500 times / second, and the ultrasonic power is 2400W; the cooling water flow rate in the crystallizer is 4.63t / h.

[006...

Embodiment 2

[0069] Embodiment 2: AZ80 magnesium alloy Ingot frequency conversion ultrasonic semi-continuous casting

[0070] In this example, the AZ80 magnesium alloy is smelted according to the ratio; casting starts when the temperature of the tundish is 670°C, and continuous frequency conversion ultrasonic treatment is applied to the melt during the casting process. Compressed air in the system for cooling.

[0071] Casting process conditions: casting speed: 30mm / min, will The 304 stainless steel ultrasonic radiation rod is baked with acetylene to 610°C; the set ultrasonic basic frequency is 25kHz, the frequency change rate is 300 times / second, and the ultrasonic power is 6000W; the cooling water flow rate in the crystallizer is 11.3t / h.

[0072] Fig. 11 (a)~(d) are traditional DC casting, traditional single-frequency ultrasonic semi-continuous casting and the present invention figure 1 The AZ80 magnesium alloy cast by the frequency conversion ultrasonic semi-continuous casting met...

Embodiment 3

[0074] Embodiment 3: ZK60 magnesium alloy Ingot frequency conversion ultrasonic semi-continuous casting

[0075] In this embodiment, each ingredient is melted and refined in an alloy melting furnace according to the ratio of the ZK60 magnesium alloy; casting starts when the temperature of the tundish is 660°C, and an ultrasonic radiation rod is inserted below the liquid surface of the melt during the casting process. The melt is subjected to continuous frequency conversion ultrasonic treatment, and the compressed air in the frequency conversion ultrasonic system is cooled by piezoelectric ultrasonic transducers and eddy current cooling tubes.

[0076] Casting process conditions: casting speed: 40mm / min, will The 304 stainless steel ultrasonic radiation rod is baked with acetylene to 600°C; the set ultrasonic basic frequency is 15kHz, the frequency change rate is 20 times / second, and the ultrasonic power is 4000W; the cooling water flow rate in the crystallizer is 5.34t / h. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com