Preparation method of alloy semisolid slurry

A semi-solid slurry and alloy technology, applied in the field of alloy semi-solid slurry preparation, can solve problems such as poor slurry uniformity, and achieve the effect of promoting equiaxed growth and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

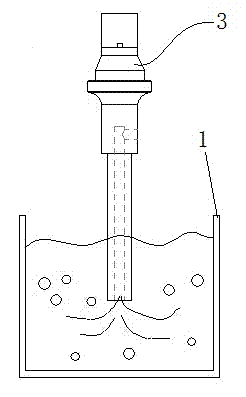

[0035] Embodiment 1: The ZL101 aluminum alloy is used for smelting to prepare a semi-solid molded part. The liquidus temperature of ZL101 aluminum alloy is 615°C, and the solidus temperature is 567°C. The alloy is heated to 700°C in the heating furnace, and the slurry container is taken out of the molten aluminum alloy from the heating furnace.

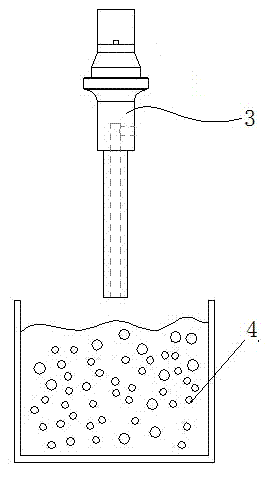

[0036]The elongated probe 6 is inserted 20mm below the aluminum alloy liquid surface through the lifting device, and dry nitrogen at a temperature of 15°C is introduced from the elongated probe 6 under the aluminum alloy liquid surface, and the treatment time for both is 2Min. The ultrasonic vibration frequency is 28KHz, the vibration amplitude is 0.5mm, and the nitrogen gas feeding rate is 15L / Min. After the processing time is in place, lift the slender probe 6 to 100mm above the liquid level with the lifting device, and the slurry container sends the aluminum alloy semi-solid slurry into the material chamber of the die-casting mach...

Embodiment 2

[0037] Example 2: The ZL109 aluminum alloy was smelted to prepare a semi-solid molded part. The liquidus temperature of ZL109 aluminum alloy is 566°C, and the solidus temperature is 538°C. The alloy is heated to 700°C in the heating furnace, and the slurry container is taken out of the molten aluminum alloy from the heating furnace.

[0038] like Figure 5 As shown, the slender probe 6 is inserted 20mm below the aluminum alloy liquid surface through the lifting device, and dry nitrogen at a temperature of 15°C is introduced from the external air guide tube 7 under the aluminum alloy liquid surface, and the treatment time for both is 1.5Min. The ultrasonic vibration frequency is 28KHz, the vibration amplitude is 1mm, and the nitrogen gas feeding rate is 15L / Min. After the processing time is in place, the lifting device lifts the slender probe 6 to 100mm above the liquid surface, and the slurry container sends the aluminum alloy semi-solid slurry into the material chamber of t...

Embodiment 3

[0039] Embodiment 3: AZ61 magnesium alloy is used for smelting to prepare a semi-solid molded part. The liquidus temperature of AZ61 magnesium alloy is 595°C, and the solidus temperature is 470°C. The alloy is heated to 700°C in the heating furnace, and the slurry container is taken out of the molten magnesium alloy from the heating furnace.

[0040] Insert the elongated probe 6 into the magnesium alloy liquid surface 20mm below the magnesium alloy liquid surface through the lifting device, and at the same time, dry nitrogen gas at a temperature of 15°C is introduced from the elongated probe 7 into the magnesium alloy liquid surface, and the treatment time for both is 1Min. The ultrasonic vibration frequency is 50KHz, the vibration amplitude is 1mm, and the nitrogen gas feeding rate is 25L / Min. After the processing time is in place, lift the slender probe 6 to 100mm above the liquid surface by the lifting device, and the slurry container sends the magnesium alloy semi-solid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com