Method for enhancing gas-liquid process in micro-reactor

A micro-reactor, gas-liquid technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems such as poor mass transfer effect, to prevent dredging blockage, gas absorption rate Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 gas-liquid physical absorption process strengthening

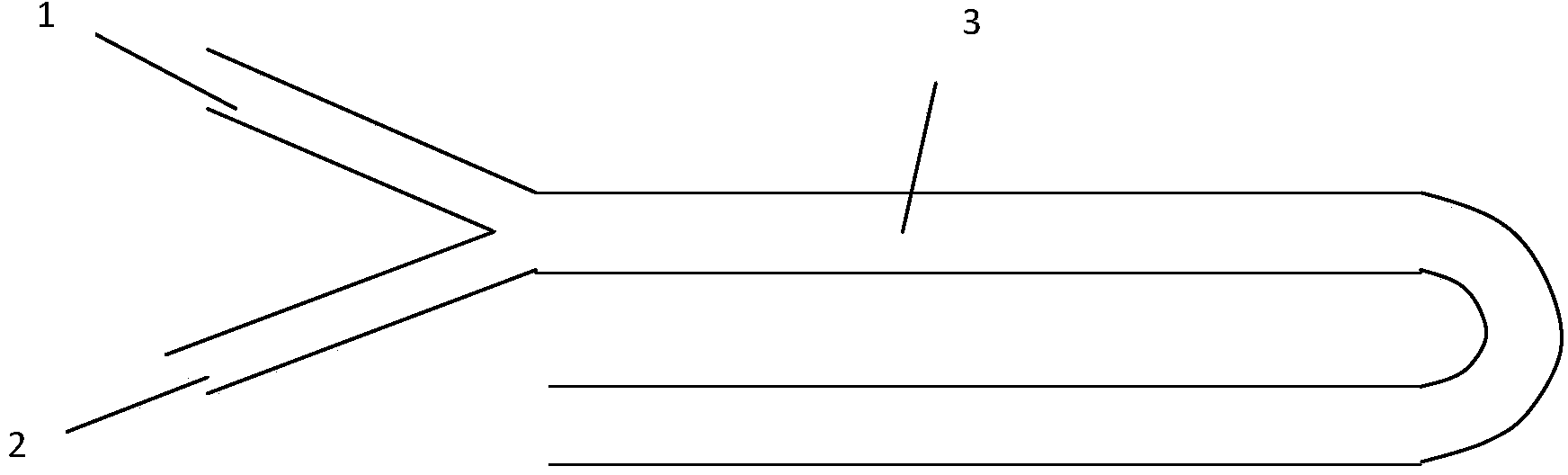

[0023] This embodiment takes the use of ultrasound to strengthen the physical absorption process in a gas-liquid microreactor as an example. In the liquid inlet channel 1 of the microchannel, deionized water was introduced with a flow rate of 2ml / min, and pure carbon dioxide was introduced into the gas inlet channel 2 with a flow rate of 1.65ml / min. like figure 2 As shown, the injected gas forms a continuous slug flow in the main channel 3, and the transverse equivalent diameter of the bubbles is about 1000 μm. When no ultrasound is added, the absorption rate is 26.7% due to the absorption of carbon dioxide by water. When the working frequency is 20kHz and the sound intensity is 1.5W / cm 2 During ultrasonication, the gas-liquid mass transfer is accelerated, and the absorption rate of carbon dioxide is 56.3%. According to the mass transfer model, the gas-liquid total volume mass transfer coefficient ...

Embodiment 2

[0024] Embodiment 2 gas-liquid chemical absorption process intensification

[0025] This embodiment takes the use of ultrasound to strengthen the chemical absorption process in a gas-liquid microreactor as an example. In the liquid inlet channel 1 of the microchannel, 20% mass fraction of monoethanolamine MEA (molecular formula NH 2 CH 2 CH 2 OH) solution, the flow rate is 1ml / min, and 10% carbon dioxide gas (the balance gas is nitrogen gas) is introduced into the gas inlet channel 2, and the flow rate is 20ml / min. The cross-sectional diameter is about 900 μm. After the gas and the MEA solution pass into the main channel 3, they contact each other for mass transfer and chemical reaction occurs so that carbon dioxide is chemically absorbed by the MEA solution. The material that has been reacted at the outlet of the reactor is separated from gas and liquid by a commonly used gas-liquid separation tank, and the concentration of carbon dioxide in the gas is measured by a carbo...

Embodiment 3

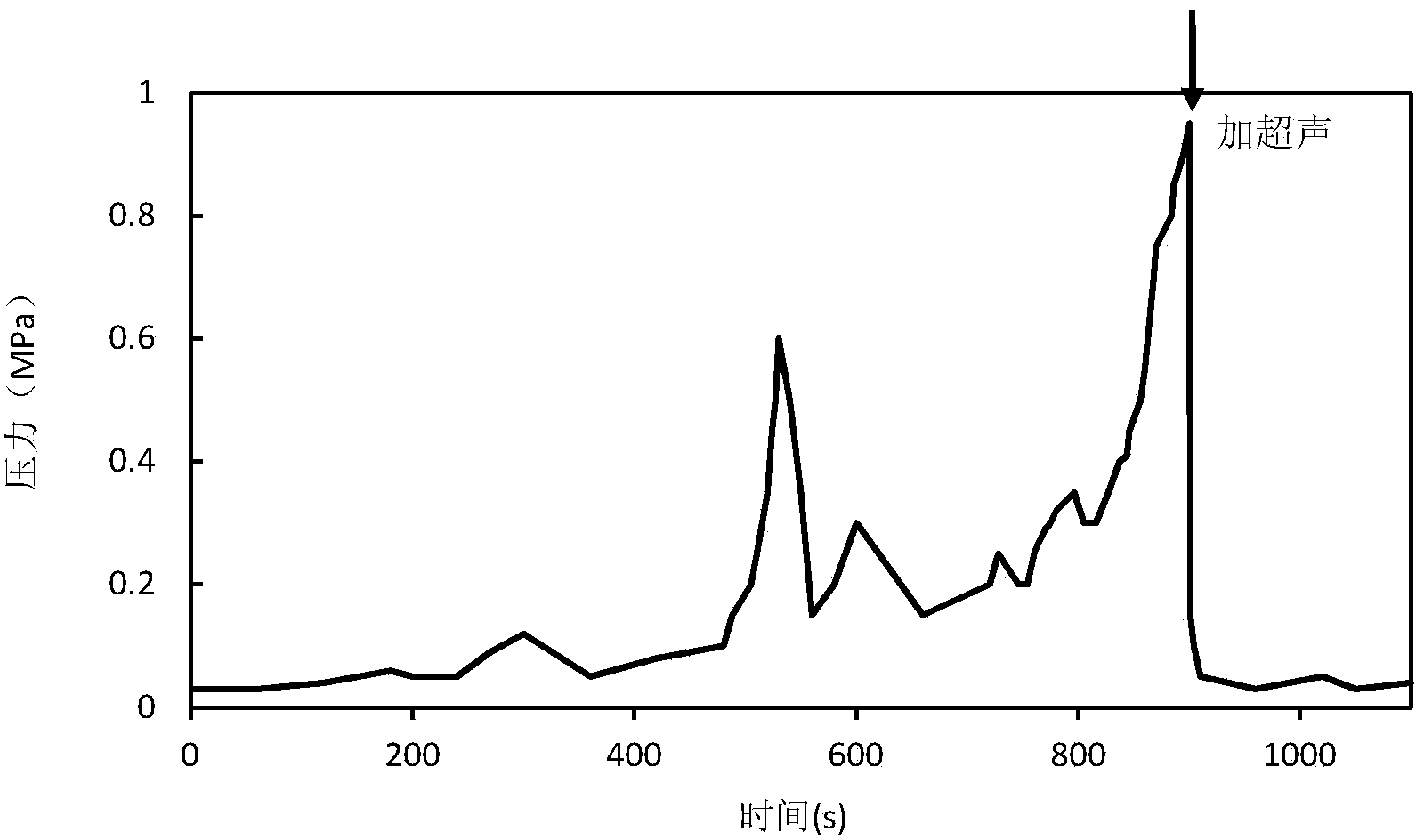

[0026] Embodiment 3, the gas-liquid reaction process strengthening of generating solid

[0027] In this embodiment, the gas-liquid reaction process of solid formation is strengthened by ultrasound in a gas-liquid microreactor as an example. In the liquid inlet channel 1 of the microchannel, 5% (NH 4 ) 2 SiF 6 Solution, flow rate 10ml / min, feed pure NH in gas inlet channel 2 3 Gas, flow rate 10ml / min. (NH 4 ) 2 SiF 6 solution and NH 3 After the gas is passed into the main channel 3, a slug flow is formed, and the mass transfer occurs through contact with each other, and a chemical reaction occurs to form silicon oxide solid particles. When no ultrasound is applied, the silicon oxide solid particles generated in the main channel 3 are deposited on the wall of the channel, and accumulate more and more over time, and the pressure drop gradually increases accordingly. After about 15 minutes, channel 3 is blocked, and the pressure drop rises to 0.95MPa (see figure 2), no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com