Acoustic surface wave sorting chip undergoing special wettability optimization

A surface acoustic wave and wettability technology, applied in the field of surface acoustic wave sorting chips, can solve the problems of low flux, low sorting accuracy, and high flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

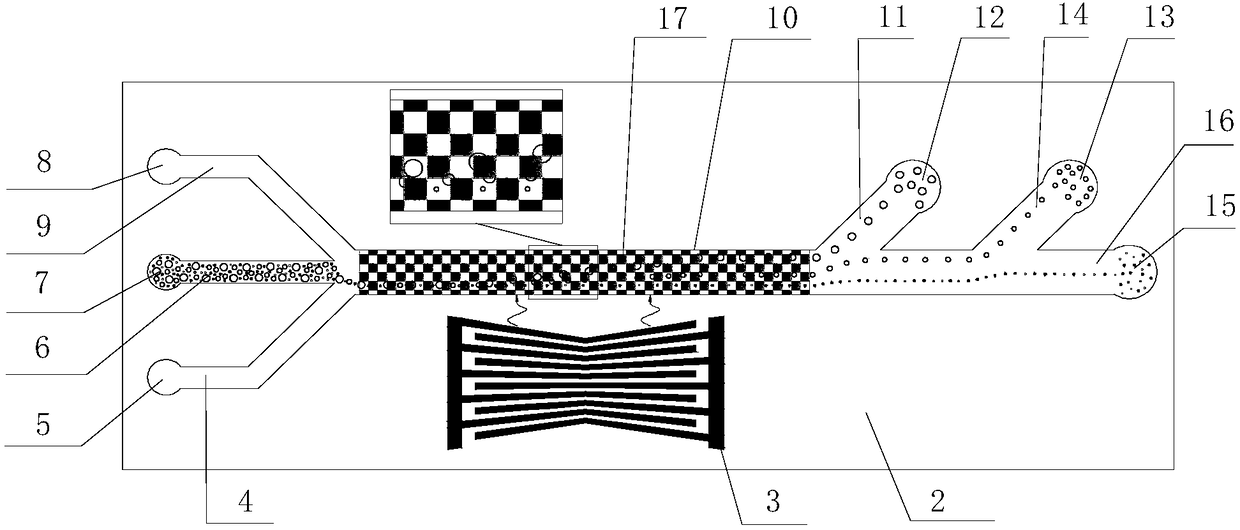

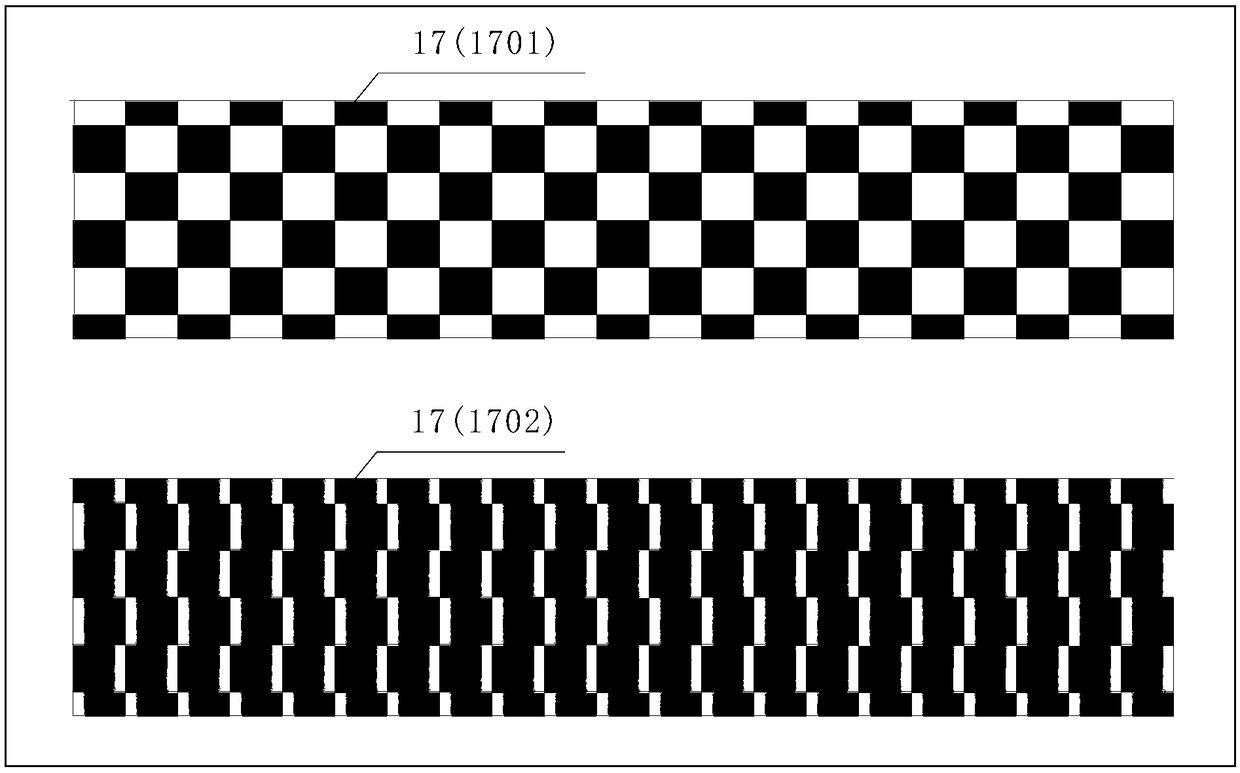

[0022] The present invention proposes a surface acoustic wave sorting chip optimized by special wettability, which integrates special wettability optimization, broadband / frequency conversion interdigital transducer (IDT) technology, partial characteristics of hydraulic separation and surface acoustic wave sorting method Combined, it can be used for sorting chips based on traveling wave surface acoustic wave sorting principle (such as embodiment 1) and sorting chips based on standing wave surface acoustic wave sorting principle (such as embodiment 2), to realize cell / particle High-throughput enrichment and high-purity sorting of specific cells.

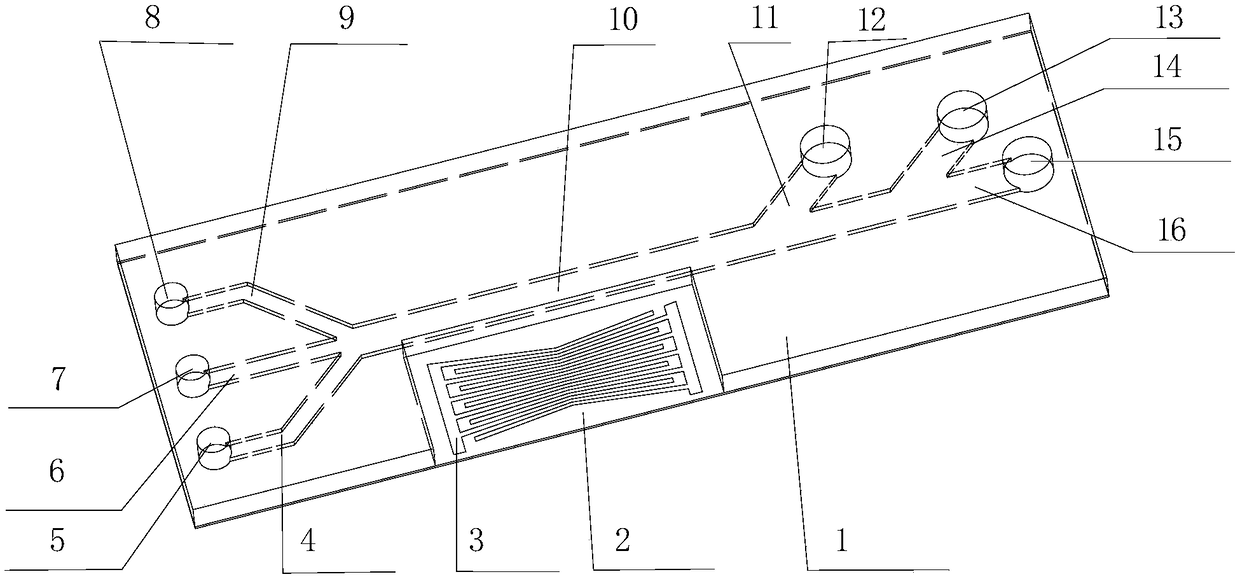

[0023] The structural reference of embodiment 1 of the present invention figure 1 , image 3 and Figure 6 :

[0024] refer to figure 1 , the chip is mainly composed of a piezoelectric substrate (2), a double-trapezoidal broadband interdigital transducer (3) and a microfluidic system (1), wherein the microfluidic system (1) include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com