Method and device for directionally solidifying liquid/solid interface based on ultrasonic wave modulation

A technology of directional solidification and liquid-solid interface, which is applied in self-solidification, chemical instruments and methods, crystal growth, etc., can solve the problem of increasing energy consumption and manufacturing costs, reducing the mechanical properties and physical properties of single crystals, and reducing product qualification rates, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

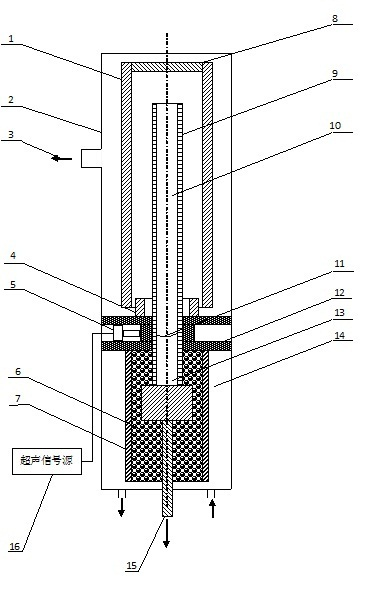

[0018] This method is based on ultrasonic modulation of directional solidification liquid-solid interface, characterized in that: add a group of ultrasonic waves near the liquid-solid interface on the periphery of the crystallizer, use the ultrasonic acoustic flow phenomenon to stir the liquid phase; control the ultrasonic acoustic flow by changing the ultrasonic frequency and power Stirring intensity of the liquid phase, and then realize the modulation of the shape of the directional solidification liquid-solid interface.

Embodiment 2

[0020] This experimental example is basically the same as the experimental example 1. The special feature is that ultrasonic stirring stirs the liquid phase within a small scale at the front of the liquid-solid interface, does not affect the longitudinal temperature gradient of directional solidification, and eliminates the radial temperature difference and concentration difference. Thus, a flat liquid-solid interface shape is obtained. The size of the acoustic flow generated by ultrasonic waves is related to the power and frequency of the ultrasonic waves. ,in, U is the maximum possible velocity of the acoustic flow, f is the ultrasonic frequency, A is the maximum amplitude of the end face of the horn. In addition, the sound pressure amplitude generated by ultrasonic waves in the liquid phase P It is lower than the ultrasonic cavitation threshold of the liquid phase, avoiding the adverse effects of cavitation on directional solidified tissue; the sound pressure amplitude...

Embodiment 3

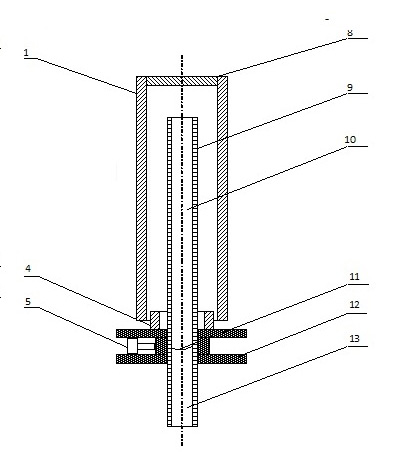

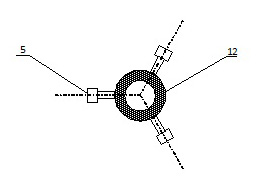

[0022] The device based on ultrasonic wave modulation directional solidification interface is used in the above method, including a furnace body (2), which is characterized in that a heat insulation layer structure (12) is slid and inserted in the middle of the inner cavity of the furnace body (2). The root tube-shaped corundum crucible (9), while the heat insulation layer structure (12) separates the inner cavity of the furnace body (2) into upper and lower furnace chambers; The inner cavity of the upper section of the tubular corundum crucible (9) stores the liquid phase sample (10), and the periphery is equipped with a graphite auxiliary heating body (4) and a graphite tube main heating body (1). There is a boron carbide cover (8) on the top of the heating body (1); multiple ultrasonic transmitting probes (5) are evenly installed in the axial direction in the heat insulation layer structure (12), and all ultrasonic transmitting probes (5) are externally connected to ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com