Additive manufacturing and surface polishing synchronous processing method and device

A technology of additive manufacturing and surface polishing, applied in the direction of additive processing, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult and complex surface polishing, inability to use inner surface polishing, etc., to achieve the effect of high-performance additive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

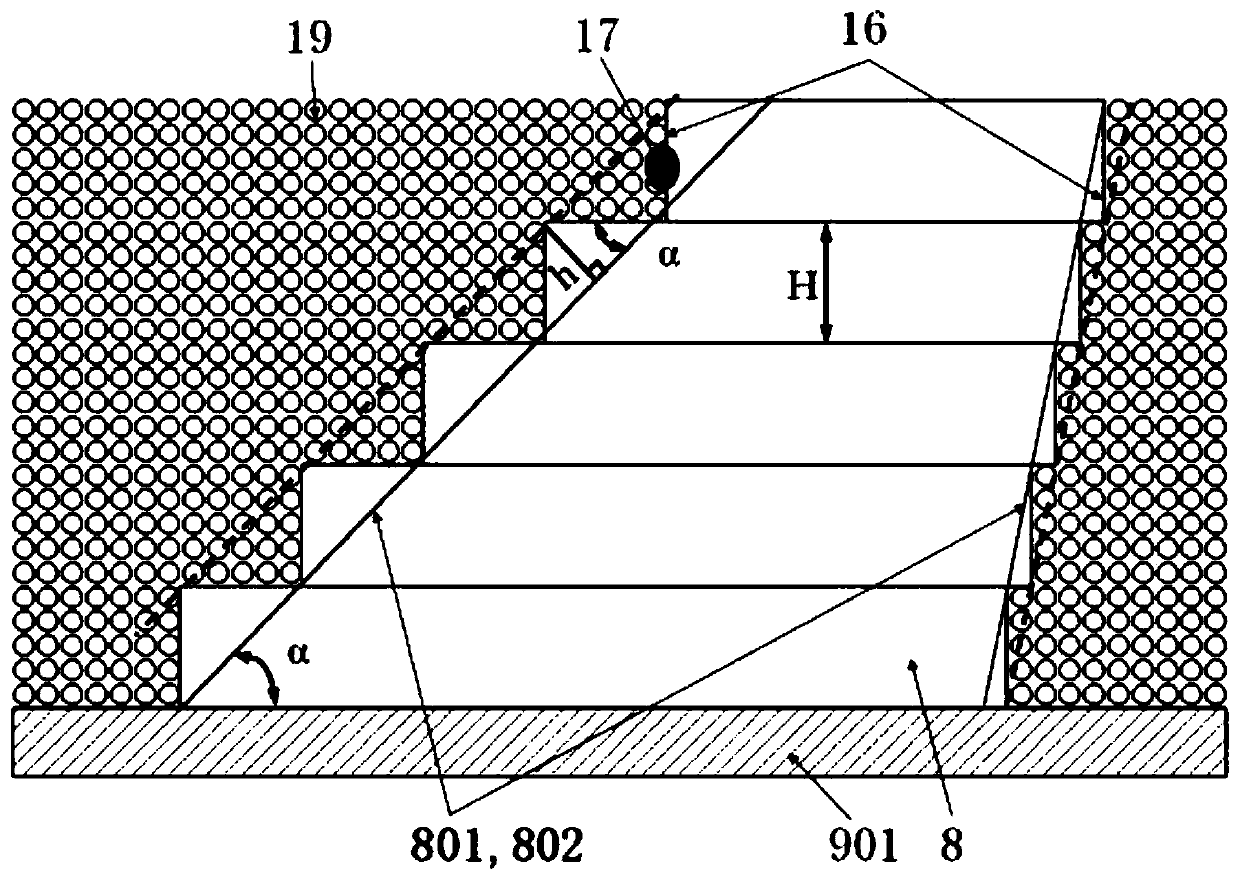

[0034] Such as figure 1 As shown, in theory, it can be considered that the surface roughness Ra of the additively manufactured part 8 should be equal to the height h of the triangle of the sheet step 16. According to the relationship of geometric dimensions, it can be known that h=H*cosα (H is the thickness of the sheet, and α is the inclination of the surface of the part Angle), it can be seen that when the thickness of the sheet step 16 is constant, the surface roughness Ra has a cosine curve relationship with the surface inclination angle of the part, that is, the smaller the surface inclination angle, the greater the surface roughness; and when the surface inclination angle is constant, the surface roughness Ra increases linearly with sheet thickness.

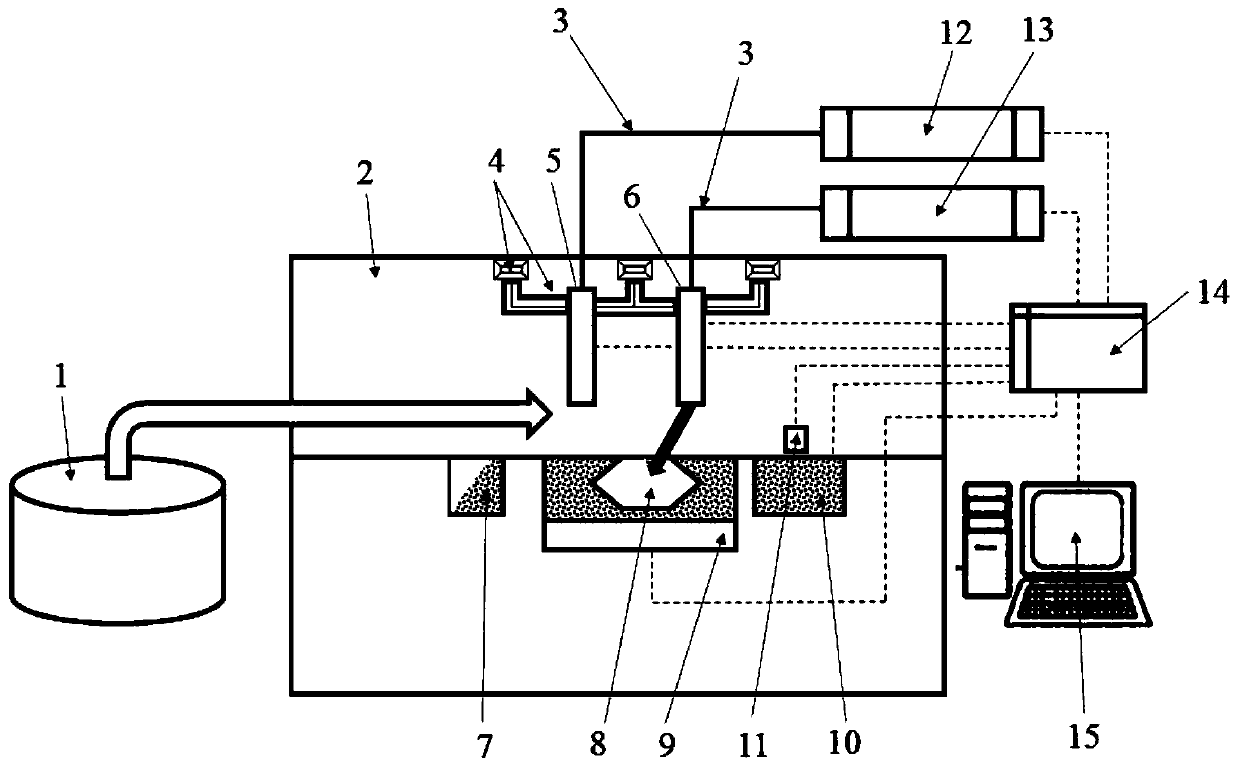

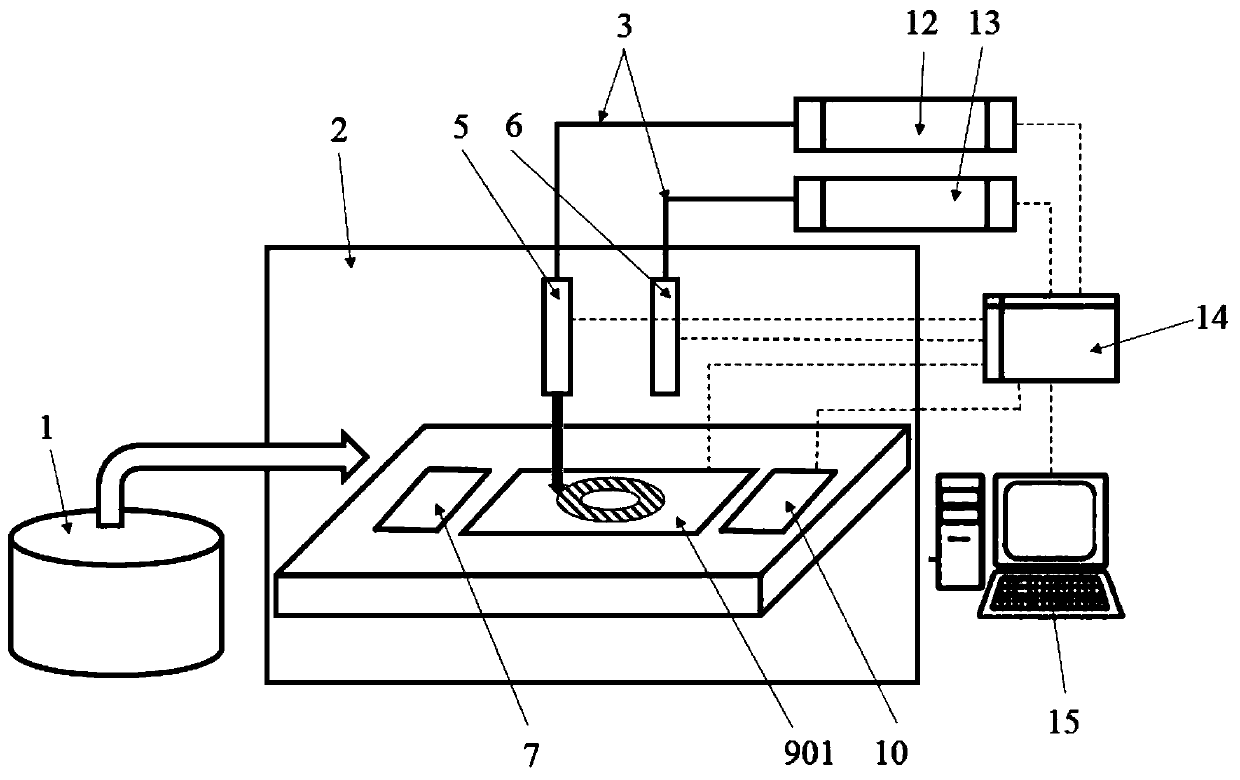

[0035] Such as Figure 4 As shown, in the layer-by-layer forming process of additively manufactured parts, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com