Method for laser polishing of surface of silicon wafer

A silicon wafer surface and laser polishing technology, which is applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of complicated process and cumbersome process, and achieve the effect of simple process, good repeatability and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

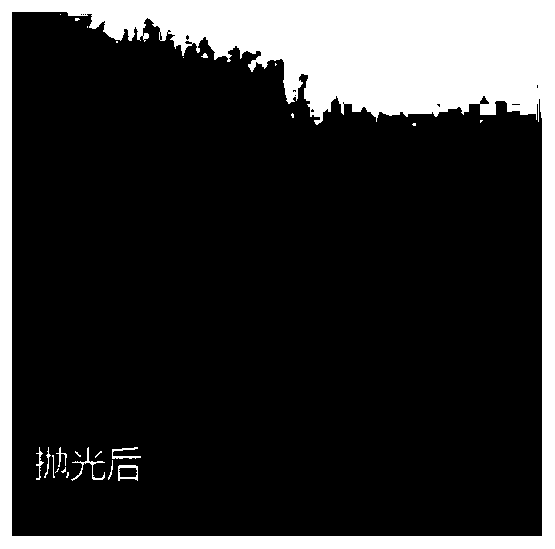

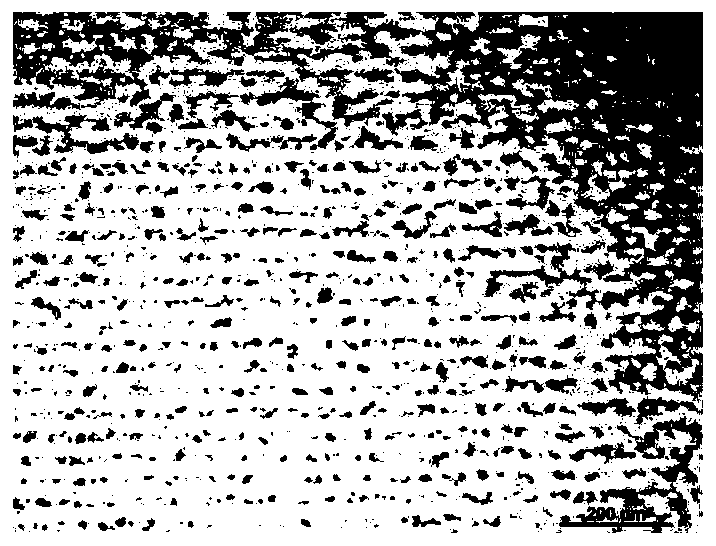

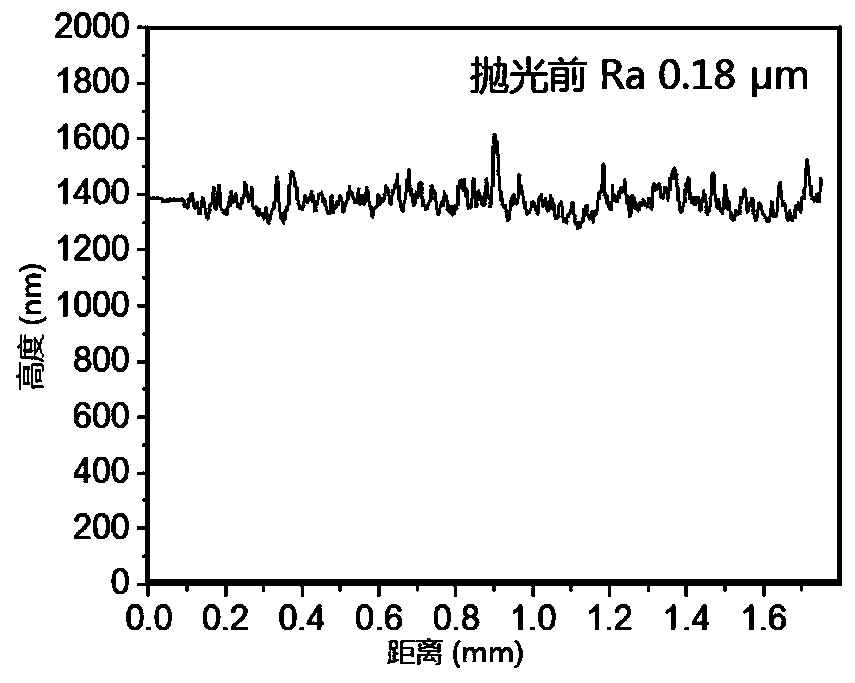

Image

Examples

Embodiment Construction

[0020] In order to better understand the content of the present invention, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The examples given are only used to explain the present invention and are not intended to limit the scope of the present invention.

[0021] A method for laser polishing a silicon wafer surface, comprising the steps of:

[0022] Step 1, put the silicon wafer to be treated into deionized water for ultrasonic cleaning, and dry the surface of the cleaned silicon wafer with cold air to obtain a silicon wafer sample with a clean surface;

[0023] Step 2: Fix the clean silicon wafer sample obtained in Step 1 on the laser processing platform, set the laser scanning process path and laser processing parameters, and use the laser processing system to scan and process the surface of the silicon wafer;

[0024] Step 3: Put the laser-treated silicon wafer sample o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com