Ultrafast laser polishing method for ceramic matrix composites

A composite material and processing method technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to ensure the uniformity of the polished surface, the processing effect is not obvious, and the operation is difficult, so as to improve the efficiency and accuracy. The effect of reducing the energy density and improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with accompanying drawing and embodiment

[0021] A method for ultrafast laser polishing of ceramic matrix composites, comprising the following steps:

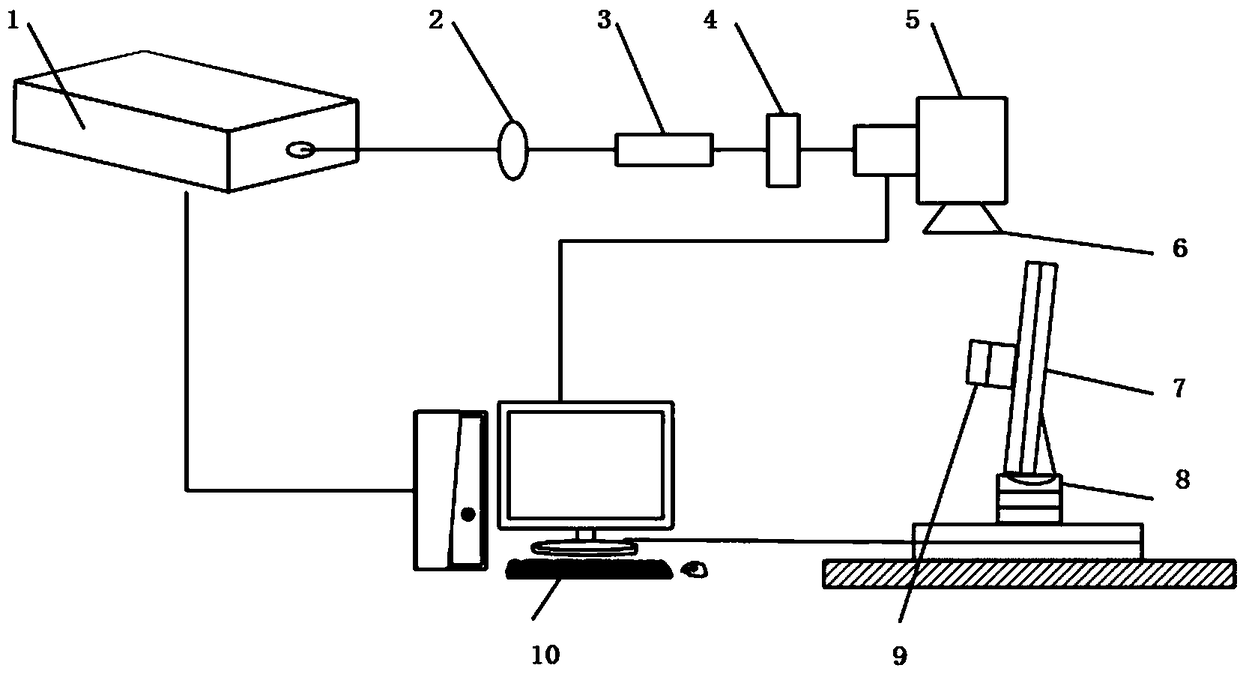

[0022] 1) Fix the 30mm*30mm SiC ceramic matrix composite sample on the laser processing equipment, refer to figure 1 The laser processing equipment includes an optical path system and a processing platform. The optical path system includes a femtosecond laser 1, and the laser light emitted by the femtosecond laser 1 passes through the reflector 2, the beam expander 3, the aperture 4, the vibrating mirror 5 and the field mirror 6 in turn. Act on the processing platform;

[0023] The processing platform includes a three-dimensional motion mechanism 7 in the x-axis direction, y-axis direction and z-axis direction relative to the worktable, and a clamp 9 for clamping the processing sample installed on the three-dimensional motion mechanism 7, the x-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com