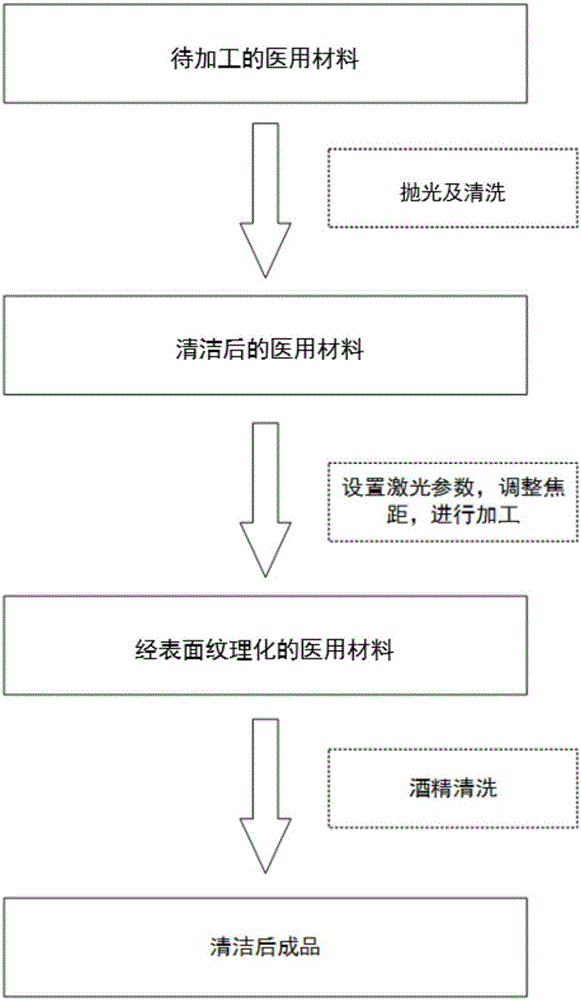

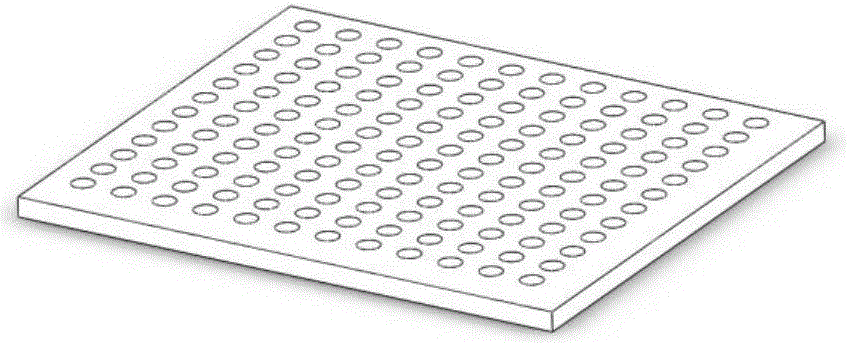

Laser veining method for improving surface cell adhesion of medical implants

An implant and adhesion technology, which is applied in the field of material surface processing, can solve problems such as incompletely clear influence mechanisms, and achieve the effects of increasing production efficiency, improving cell adhesion performance, and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1): Take a TC4 titanium alloy sheet with a thickness of 2 mm, clean it in absolute alcohol, and clean it again after mechanical grinding and polishing.

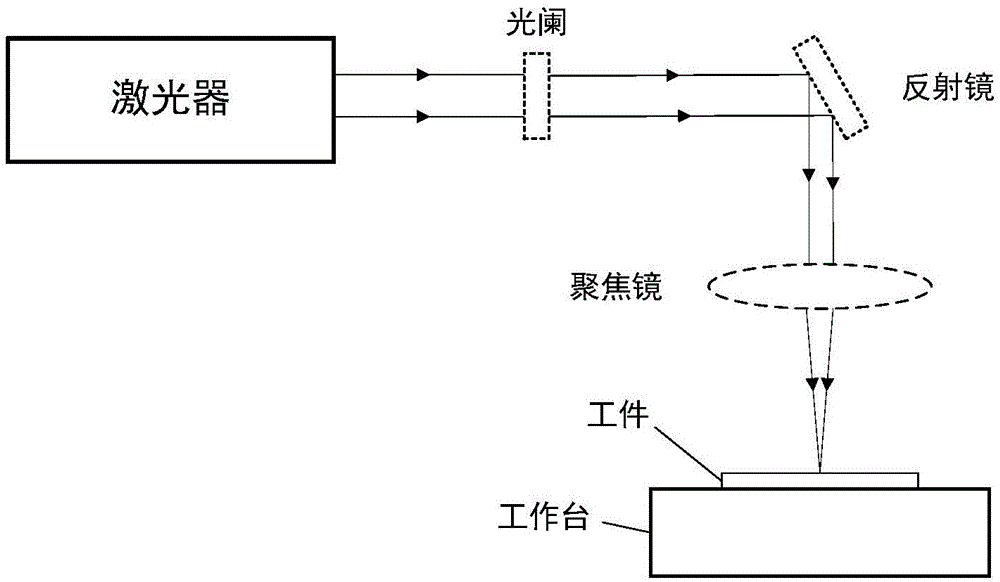

[0033] (2): Put the sample in such as figure 2 On the workbench of the picosecond laser processing system shown (using a fiber laser with a wavelength of 1060nm and a pulse width of 300ps), set the laser power to 15W, the frequency to 500KHz, the scanning speed to 200mm / s, and the scanning line spacing to 40μm. The size of the area is 15mm×15mm, the number of scanning repetitions is 5 times, and the laser processing system is started to start processing.

[0034] (3): Remove the processed titanium alloy block from the workbench and wipe it with absolute alcohol.

Embodiment 2

[0036] (1): Take a 2mm thick 316L stainless steel sheet, wash it in anhydrous alcohol, mechanically polish it and wash it again.

[0037] (2): Put the sample in such as figure 2 On the workbench of the picosecond laser processing system shown (using a fiber laser with a wavelength of 1060nm and a pulse width of 300ps), set the laser power to 20W, the frequency to 100KHz, the scanning speed to 3000mm / s, and the scanning line spacing to 70μm. The size of the area is 15mm×15mm, the number of scanning repetitions is 5 times, and the laser processing system is started to start processing.

[0038] (3): Remove the processed titanium alloy block from the workbench and wipe it with absolute alcohol.

Embodiment 3

[0040] (1): Take a Ni-Ti alloy sheet with a thickness of 2 mm, clean it in absolute alcohol, and clean it again after laser polishing.

[0041] (2): Put the sample in such as figure 2 On the working table of the shown nanosecond laser processing system (Nd:YAG laser with a wavelength of 532nm and a pulse width of 34ns), the laser power is set to 30W, the frequency is 10KHz, the scanning speed is 500mm / s, and the scanning line spacing is 100μm. Set the size of the scanning area to 15mm×15mm, the number of scanning repetitions to 5 times, and start the laser processing system to start processing.

[0042] (3): Repeat step 2 after transposing the sample by 90 degrees.

[0043] (4): Remove the processed alloy sheet from the workbench and wipe it with absolute alcohol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com