Laser beam transformation shaper outputting uniform linear spots

A laser beam, uniform line technology, applied in optics, instruments, optical components, etc., can solve problems such as unfavorable surface treatment efficiency, unfavorable surface treatment uniformity, and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

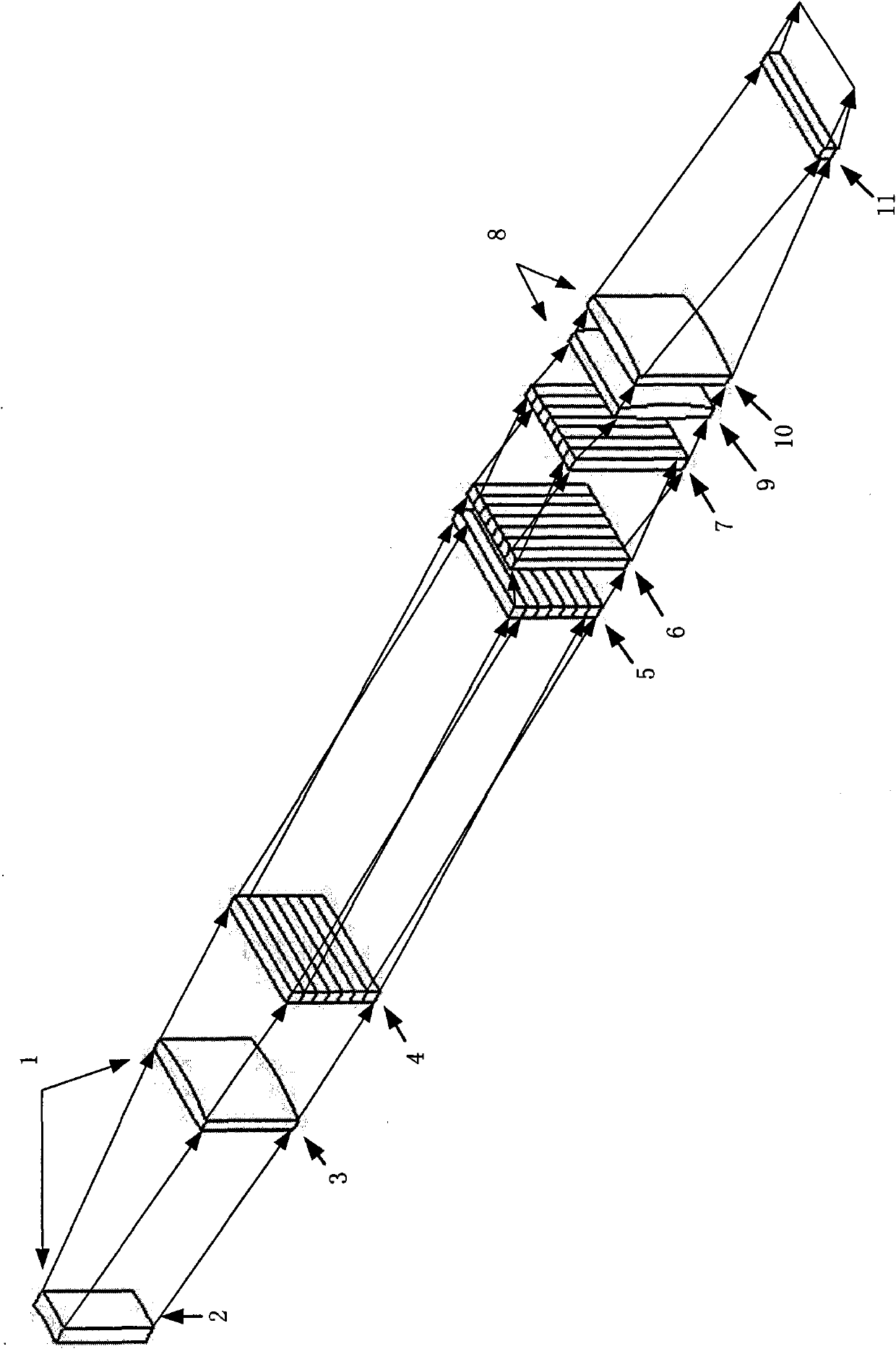

[0033] The present invention will be further described below in conjunction with accompanying drawing:

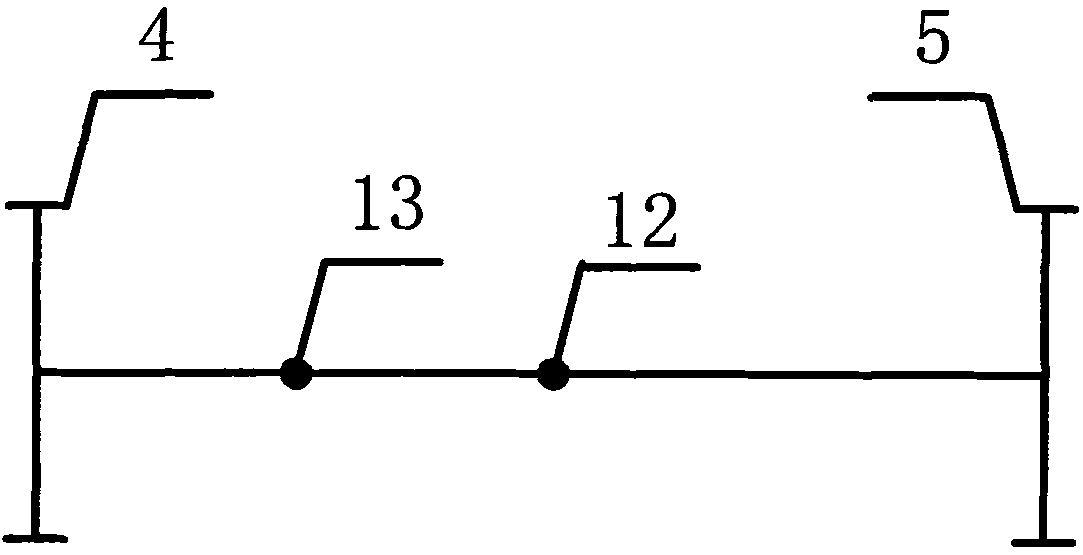

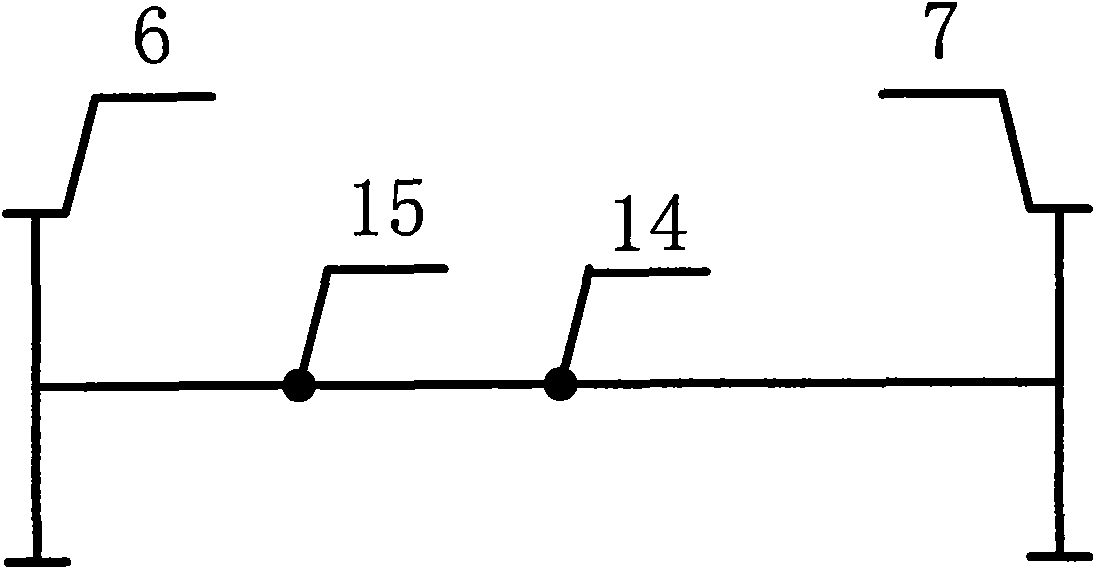

[0034] In this embodiment, the spot shape of the incident laser is rectangular (18mm × 35mm), the spot energy distribution is non-uniform distribution (18mm direction is Gaussian distribution, 35mm direction is nearly Gaussian distribution), and the central wavelength is 248nm excimer laser. Suitable for high precision laser polishing and laser cleaning. This embodiment consists of a first part 1 , a second part 4 , a third part 5 , a fourth part 6 , a fifth part 7 , a sixth part 8 and a seventh part 11 . The first part is a telescope system, which is made up of two cylindrical lenses; the second part 4, the third part 5, the fourth part 6 and the fifth part 7 are all cylindrical lens arrays, wherein the second part 4 and the third part 5 The generatrixes of the cylindrical lens array are parallel, the generatrixes of the third part 5 and the fourth part 6 are vertical, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com