Composite polishing method based on laser and plasma

A plasma and composite polishing technology, applied in the field of mechanical processing, can solve the problems of low material removal rate, poor processing quality, and low polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

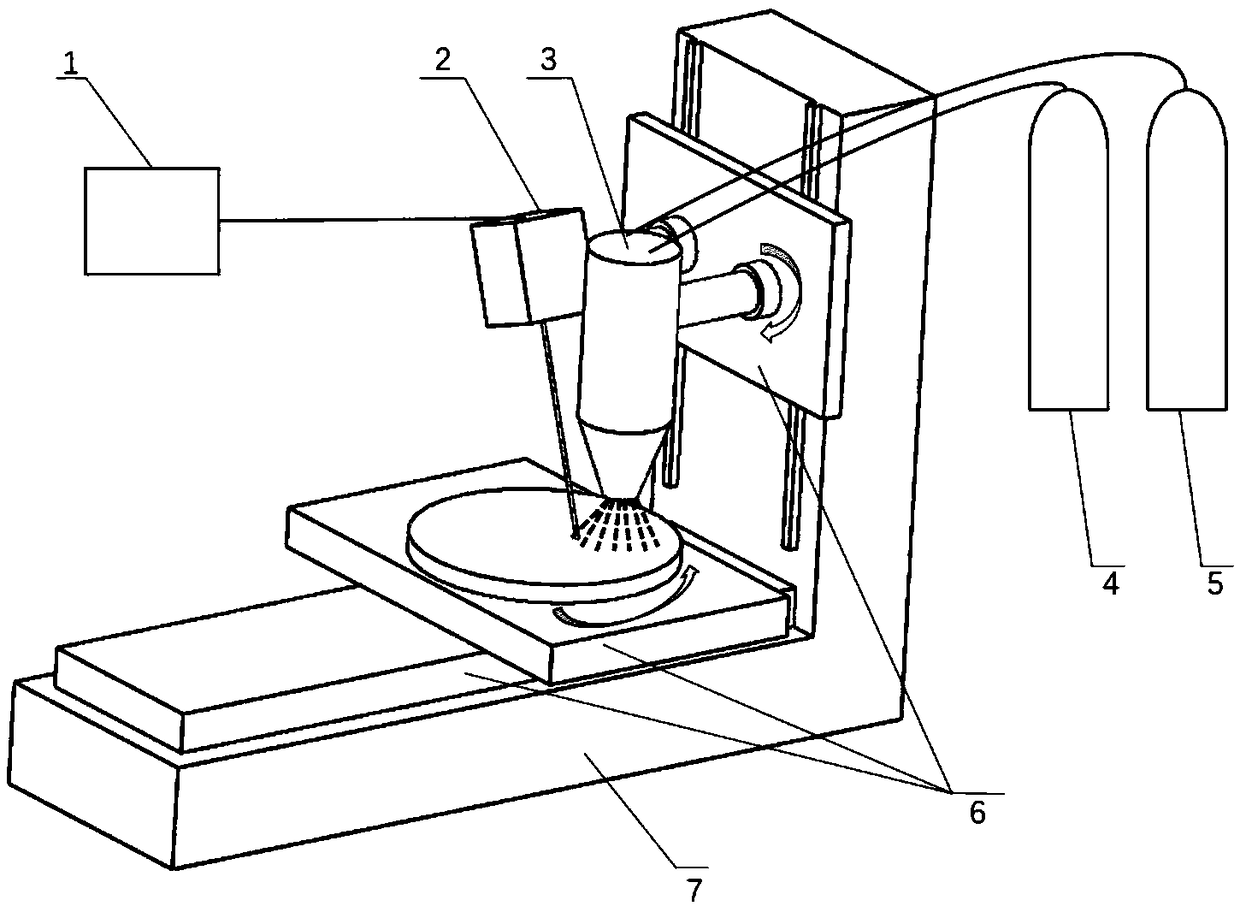

Image

Examples

Embodiment 1

[0051] 1: Take silicon carbide with a surface roughness of about 200nm-300nm, and simply clean and degrease the surface.

[0052] 2: Use a three-dimensional profiler to measure the surface to be polished.

[0053] 3: Put the silicon carbide sample in such as figure 1 On the polishing system workbench 7 of the laser plasma composite polishing system shown, the laser polishing device is set with a laser power of 30 mW, a pulse repetition frequency of 100 Hz, a laser wavelength of 800 nm, a scanning speed of 1 mm / s, and a laser beam incident angle of 50°; plasma polishing device set input power 500W, He flow rate 15L / min, O 2 The flow rate is 0.2SCCM / min. After the plasma polishing device generates a stable plasma discharge, the reaction gas CF is introduced 4 , the reactive gas CF 4 The flow rate is set to 0.15SCCM / min, and the processing system is started to start processing.

[0054] 4: Remove the processed silicon carbide from the workbench, wipe it with absolute alcohol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com