Laser polishing method of mobile phone display screen glass

A technology of laser polishing and display screen, which is applied in the field of laser polishing of mobile phone display glass, which can solve the problems of high utilization rate consumption, high cost of polishing liquid, and difficulty in improving yield rate, so as to improve yield rate, shorten production cycle, and reduce cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

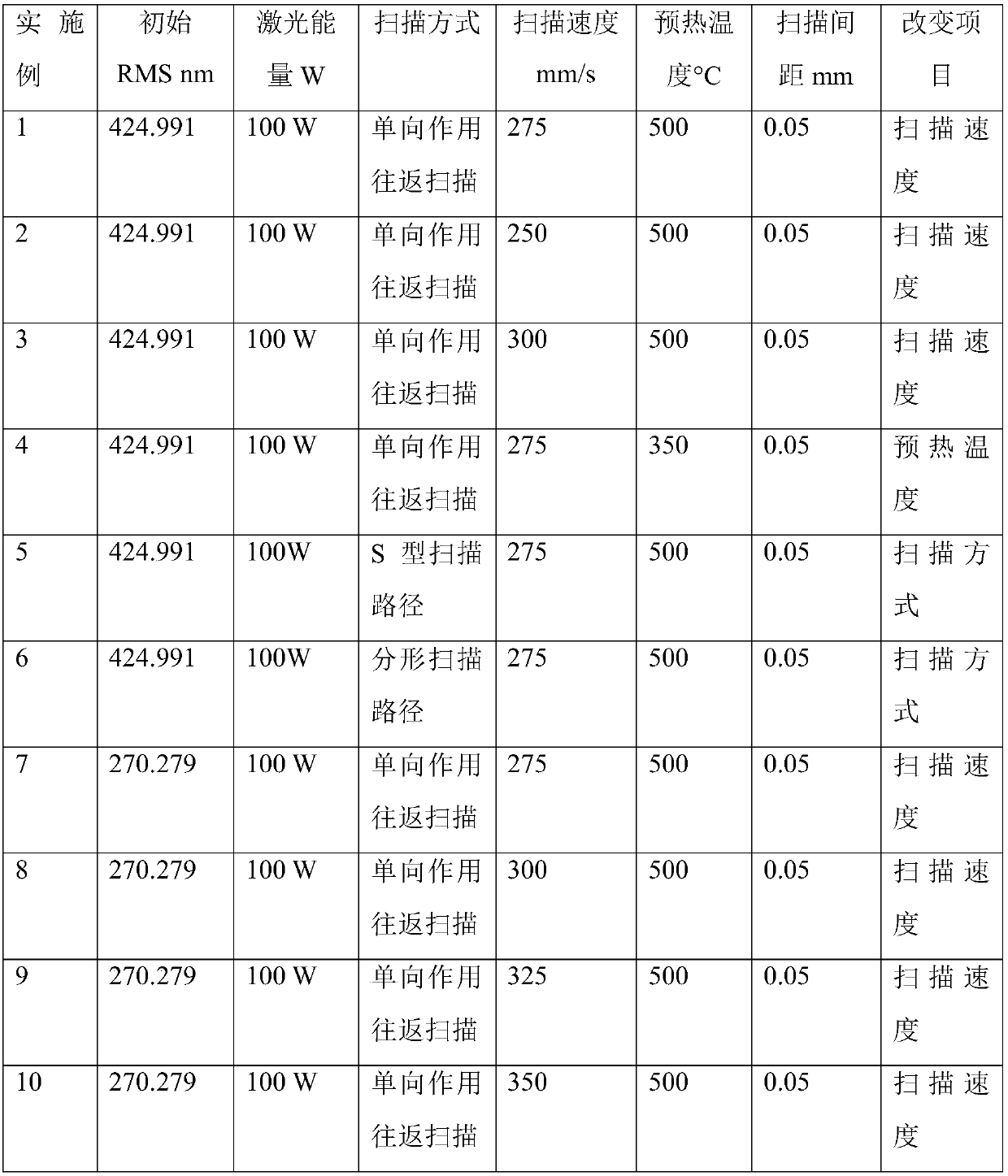

Examples

Embodiment 1

[0018] A laser polishing method for mobile phone display glass, comprising the following steps:

[0019] 1) Polishing light source setting: choose continuous CO 2 Laser light source, and use the beam shaping system to shape the Gaussian beam into a flat-topped beam with flat beam and uniform energy distribution;

[0020] 2) Preheating of mobile phone display glass: Place the clean mobile phone display glass to be polished on a uniformly heated preheating platform for preheating. The polished mobile phone screen glass is Corning Gorrilla glass, and the strain point of the glass is 571°C. The annealing temperature is 623°C, and the preheating platform is set at 500°C according to the polishing requirements;

[0021] 3) Polishing path planning and setting of other parameters: The polishing path of the polished mobile phone screen glass is selected as a plane with unidirectional action and round-trip scanning, according to the used CO 2 The energy of the laser is 100W, the diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com