Laser beam homogenization device

A technology of laser beams and chemical devices, applied in optics, optical components, instruments, etc., can solve problems such as poor imaging effects, achieve low laser energy attenuation, less difficulty in realization, and improve the effect of uniform spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

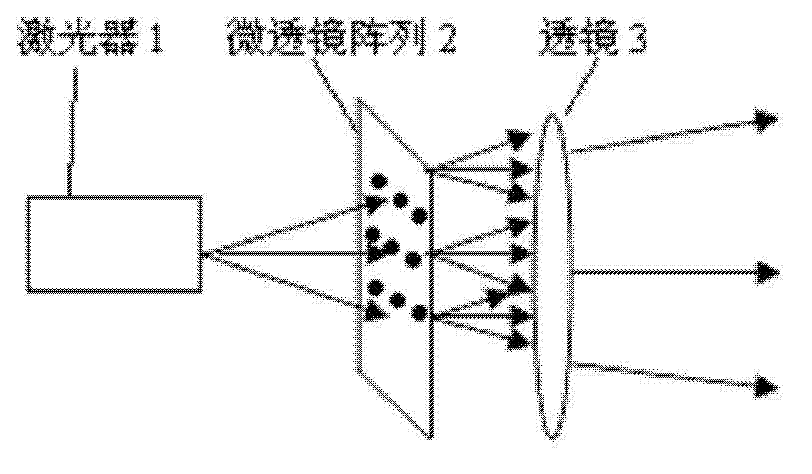

[0015] See figure 1 As shown, the present invention provides a laser beam homogenization device, including:

[0016] A laser 1; the laser 1 is a semiconductor laser, which functions as a light source to emit laser light.

[0017] A microlens array 2 consisting of a plurality of microlenses, the microlens array 2 is located on the light emitting path of the laser 1, wherein the microlens array 2 is 2 mm × 2 mm, and the spacing of each micro lens is 150 microns or 300 microns, the function of which is that when the light emitted by the laser 1 irradiates the micro lens array 2, a lot of light spots will be formed through the micro lens array 2, and each light spot is equivalent to a small light source. A small light source overlaps each other in the distance, so as to realize the uniformity of the light spot;

[0018] An emitting lens 3, wherein the emitting lens 3 is a convex lens with a focal length of 50mm. The emitting lens 3 is located behind the micro lens array 2 and on the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com