3D surface laser polishing method and device

A laser polishing and three-dimensional curved surface technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as low efficiency, loss of polishing technicians, and dependence on manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

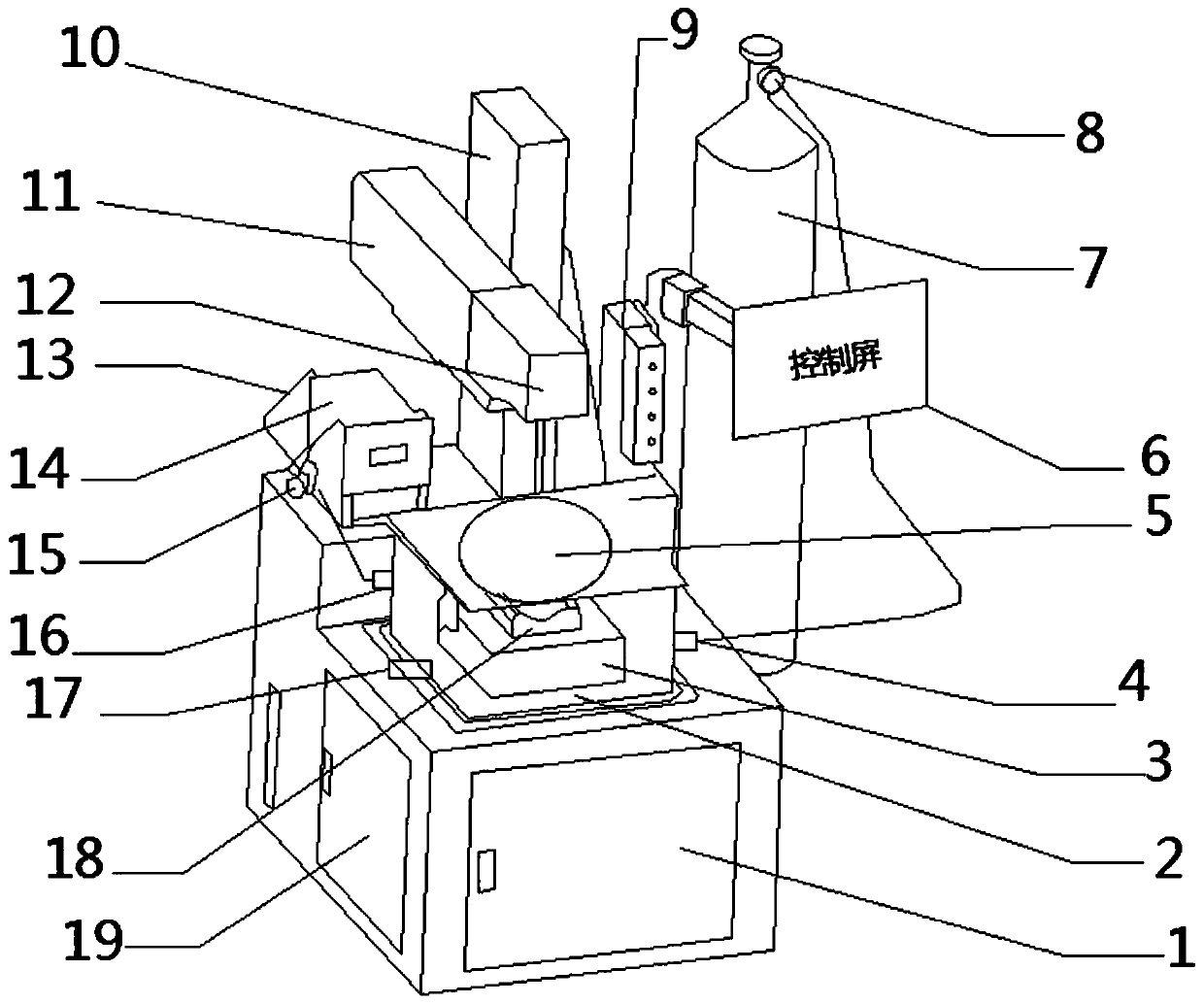

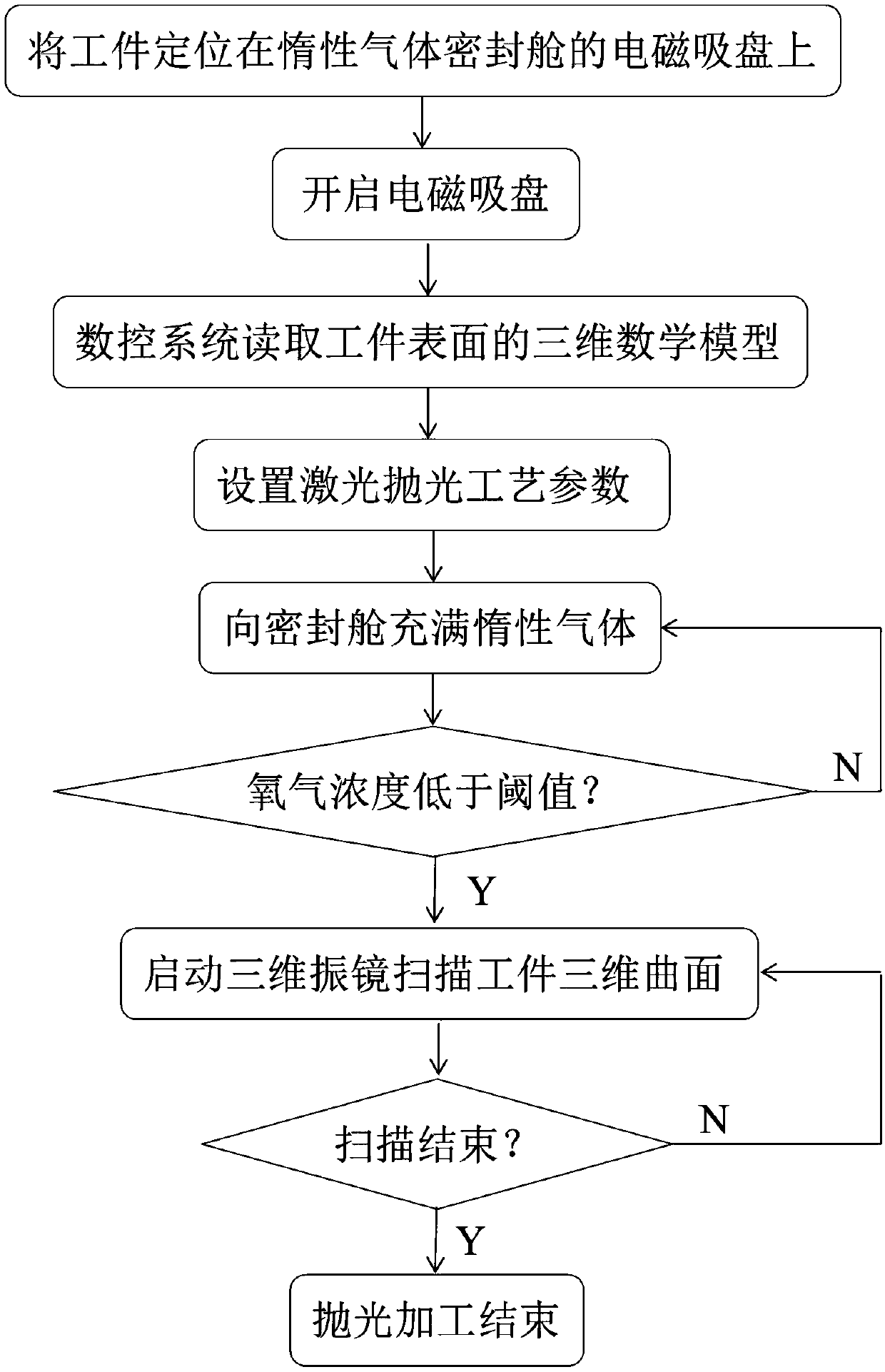

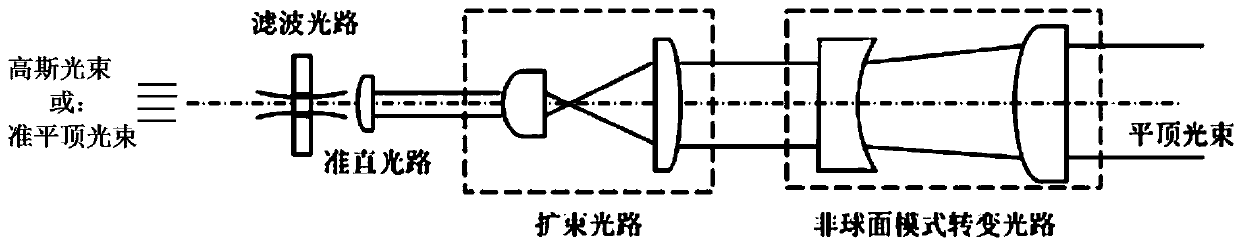

[0028] Example 1: See Figure 1-4 , a three-dimensional curved surface laser polishing equipment, including equipment bed 1, an inert gas cylinder 7, an oxygen concentration tester 14 and a built-in QBH collimator 11 with a beam expander, the inside of the equipment bed 1 is equipped with Built-in quasi-flat-top continuous laser 19, the built-in quasi-flat-top continuous laser 19 converts the quasi-flat-top beam into a flat-top beam through beam shaping technology, the diameter of the spot produced by the laser is 1-2mm, and the laser beam passes through the built-in QBH collimator and the beam expander 11, enter the three-dimensional galvanometer 12; the height of the three-dimensional galvanometer can be adjusted by moving the axis 10; the switch box 9 is provided with a laser and a close switch with the galvanometer; the laser output by the three-dimensional galvanometer penetrates through the scanning process. Quartz glass 5 acts on the three-dimensional curved surface of ...

Embodiment 2

[0040] Embodiment 2. On the basis of Embodiment 1, the built-in quasi-flat-hat continuous laser 19 of this design can also be replaced by a Gaussian beam continuous laser, and then the Gaussian beam is converted into a flat-hat beam by beam shaping technology for use in this design.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com