Laser polishing machining equipment

A laser polishing and processing equipment technology, applied in laser welding equipment, metal processing equipment, auxiliary devices, etc., can solve the problems of low automation level and precision, and achieve the effect of reasonable distribution, good application value, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

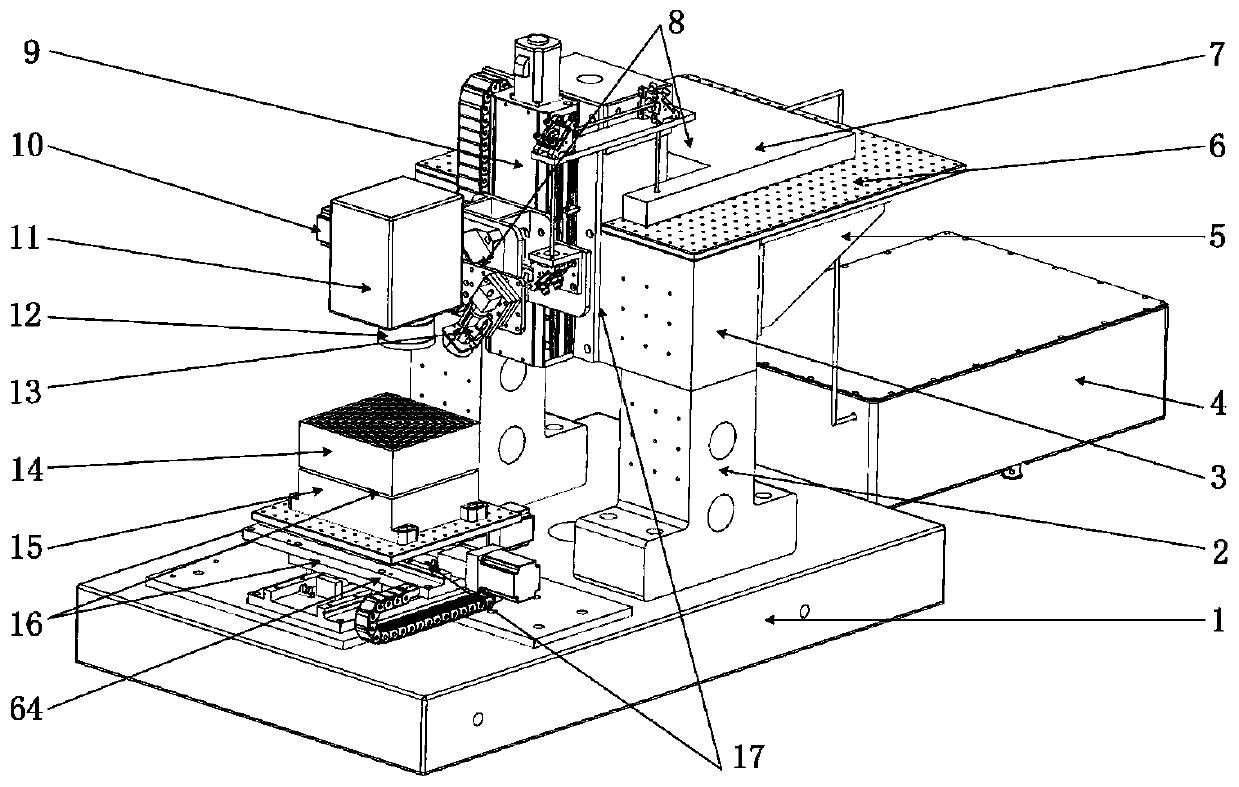

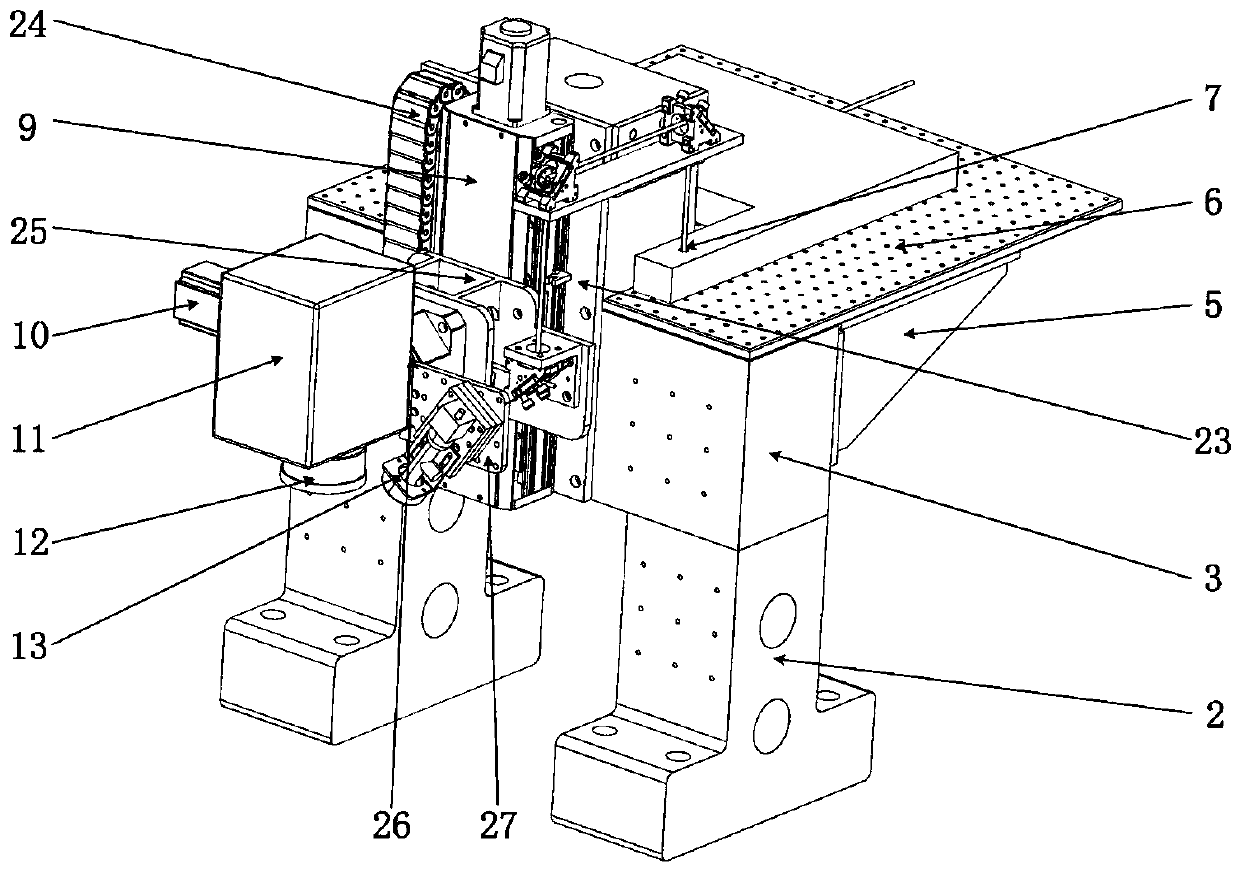

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

[0035] Such as figure 1As shown, a kind of laser polishing processing equipment provided by the present invention includes a marble base 1, a laser 4 and a machine bed 17; the machine bed 17 is installed above the marble base 1 and can be divided into two horizontal modules 16 and vertical modules 8 Part, consisting of gantry column 2, gantry beam 3, rib plate 5, optical path breadboard 6, optical path design part 7, Z-axis sliding table 9, B-axis hollow rotating platform 10, vibrating mirror 11, field mirror 12, visual inspection part 13 , XY cross moving platform 64, suction cup 14 and ultrasonic vibration device 15 etc. composition.

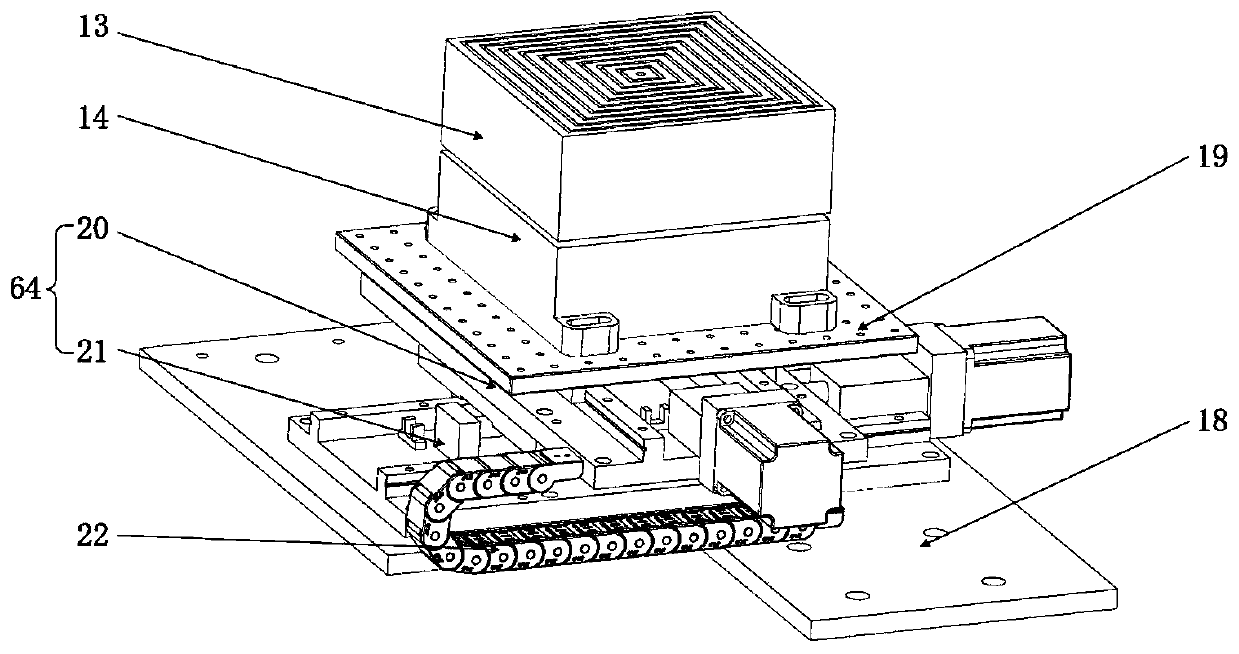

[0036] Such as figure 2 As shown, the horizontal module 16 includes a Y-axis slide table 21, an X-axis slide table 20, a first drag chain 22, a first connecting plate 18, a second connecting plate 19, an ultrasonic vibration device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com