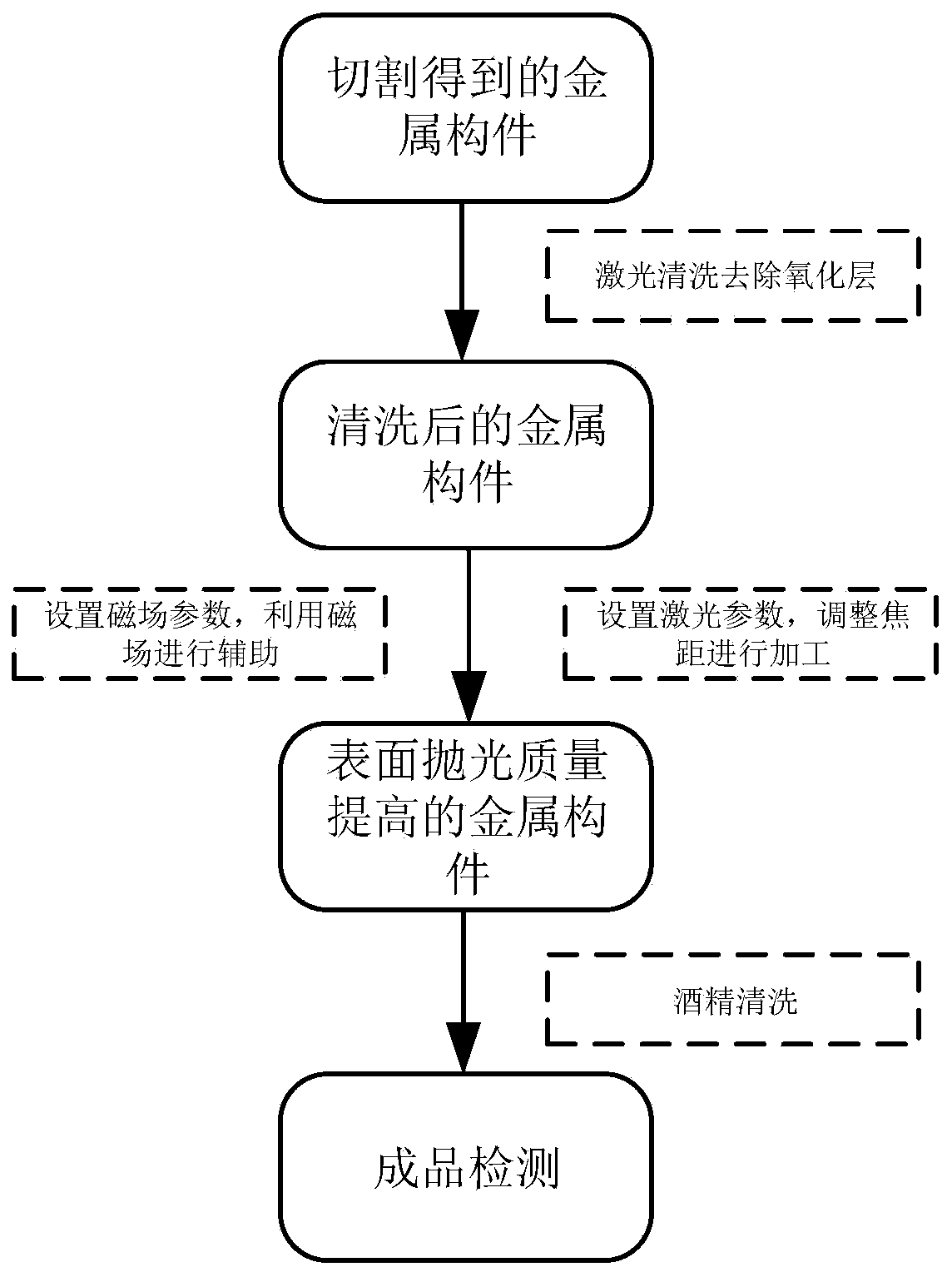

Magnetic field auxiliary laser polishing method based on existing laser processing equipment

A laser processing and magnetic field-assisted technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of short liquid molten pool time and achieve the effects of improved surface performance, strong reliability, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

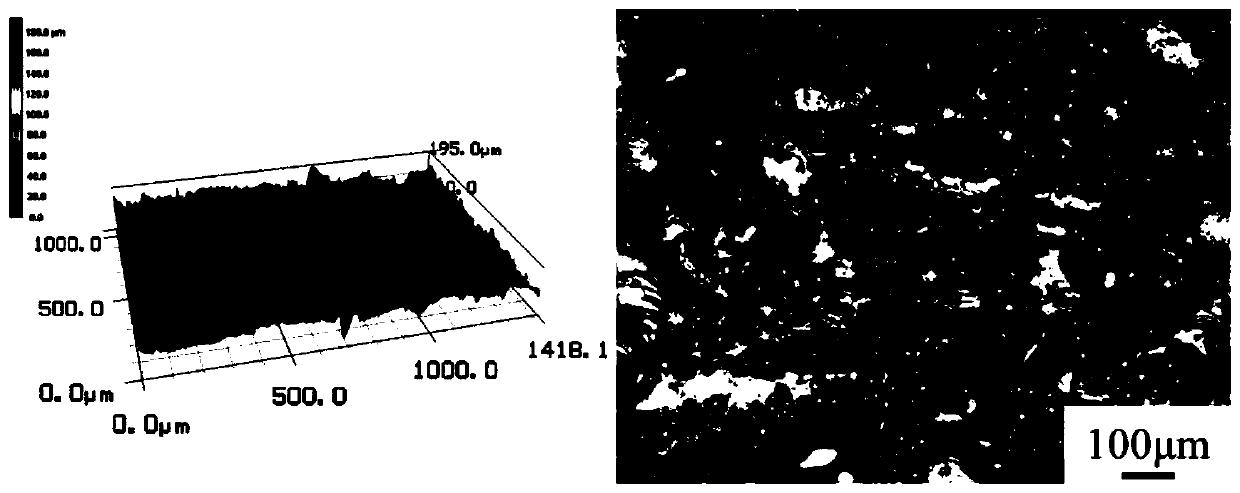

[0030] Take an Inconel 718 alloy plate with a thickness of 5mm, and use laser cleaning technology to remove oil and rust on the surface of the material. The surface characterization results are as follows figure 2 shown.

[0031] Put the workpiece in the magnetic field, and perform laser polishing without starting the magnetic field. The surface characterization results are as follows: image 3 shown;

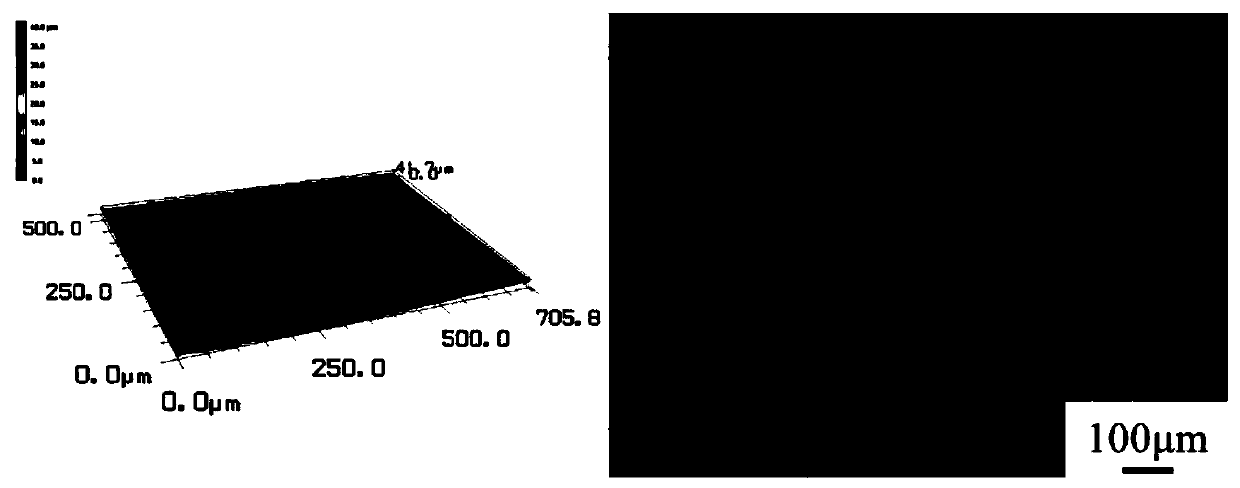

[0032] Set the magnetic field parameters: current 5A, voltage 10V, frequency 50Hz, start the magnetic field, perform laser polishing, and the surface characterization results are as follows Figure 4 shown;

[0033] Laser polishing is carried out on the workbench of the laser processing system. The polishing laser processing parameters are: laser wavelength 1064nm, laser pulse width 200ns, laser power 90W, laser repetition frequency 250kHz, beam scanning speed 50mm / s, set scanning area 8mm×8mm, scan The spacing is 20 μm, and the number of scans is 3 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com