Method for laser polishing of glass and polishing processing method of glass hole and glass sheet

A technology of laser polishing and processing method, which is applied in the field of glass sheet polishing, laser polishing glass, and glass holes, can solve the problems of fragmentation caused by surface defects, processing quality description of non-hole walls, and high energy, so as to improve the mechanical properties of glass, The effect of solving micro-cracks on the cut surface and solving the risk of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The polishing process of embodiment 1 glass hole may further comprise the steps:

[0046] 1. Use the first laser (green laser, wavelength 532nm) to irradiate the cutting outline of the preset through hole on the glass (thickness <0.2mm), and the glass is broken along the cutting outline;

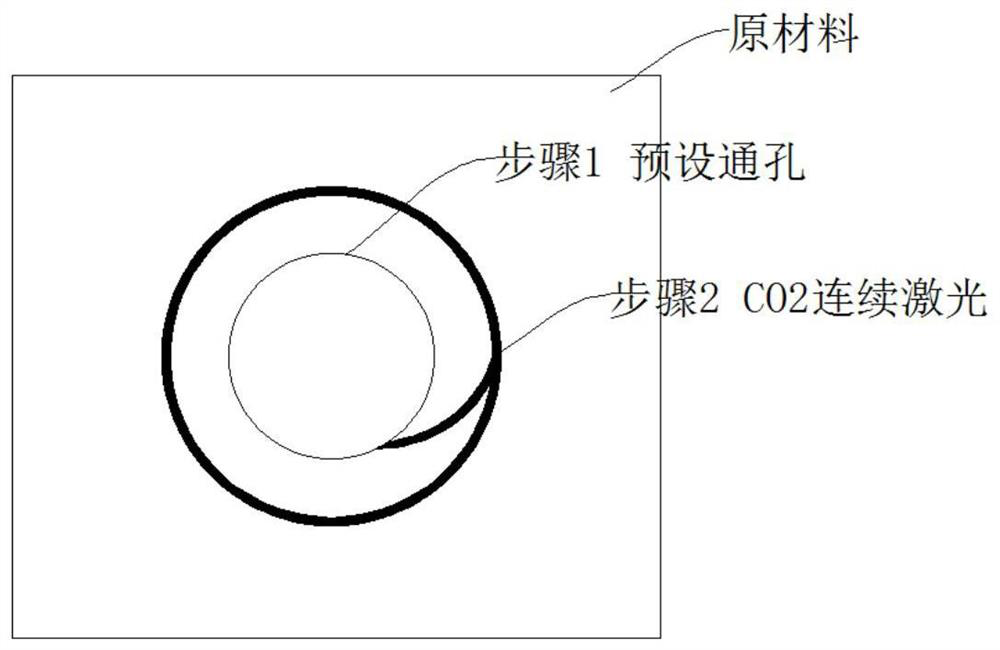

[0047] 2. Use the second laser (CO 2 Continuous laser, wavelength 10.6um, power 45-55W, spot size 10um) from the first starting point of the cut through hole to the second starting point on the polishing contour line of the glass in an arc line, and irradiate along the polishing contour line , so that the glass on both sides of the polishing contour line is evaporated to obtain a polished glass hole; the cutting contour line and the polishing contour line are concentric circles; the difference between the radius of the concentric circles is 0.5mm; as figure 1 as shown,

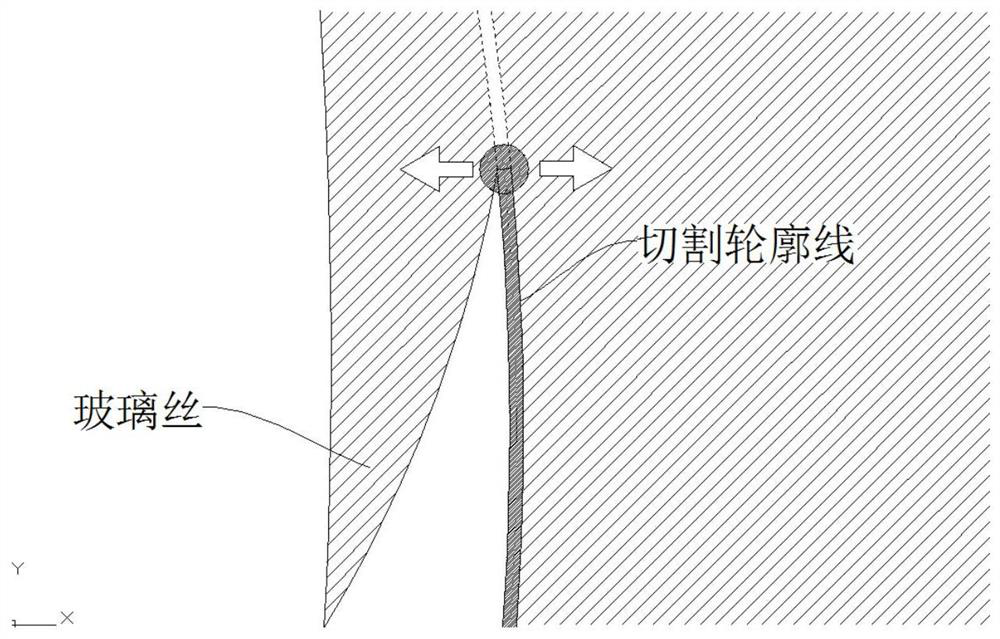

[0048] in CO 2 When the continuous laser is irradiated on a certain place on the polishing contour line, the las...

Embodiment 2

[0049] The polishing processing of embodiment 2 glass flakes

[0050] Proceed as follows:

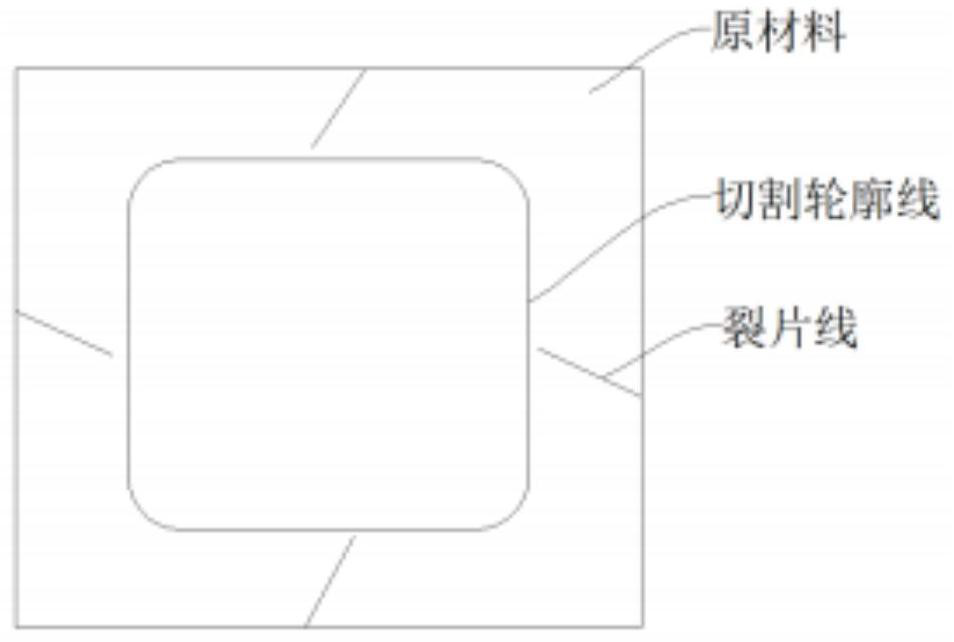

[0051] 1. Use infrared laser (pulse width of picosecond level, wavelength of 1064mm, repetition frequency of 100kHz, average power of infrared laser source of 40-50W, 6-8 repetition pulses per group, spot diameter of 3um) in a thickness of 0.1mm The high-alumina glass is irradiated along the cutting contour line of the preset glass sheet, and cracks are generated on the cutting contour line;

[0052] 2. Use infrared laser (pulse width of picosecond level, wavelength of 1064mm, repetition frequency of 100kHz, average power of infrared laser source of 40-50W, each group of repeated pulses 6-8, spot diameter of 3um) to irradiate the cutting contour of the glass sheet Outer lobes and cracks in the lobes;

[0053] The split line is 0.7-1.0 mm from the outer edge of the glass to the nearest cutting contour line; the extension line of the split line forms an angle of 30-40° with the first cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com