Method for realizing laser zirconium nitride-based amorphous alloy surface planarization through laser polishing

A technology for surface flattening and amorphous alloys, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of poor surface quality of laser zirconium nitride-based amorphous alloys, and achieve strong practicability and implementation process. Simple, roughness-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

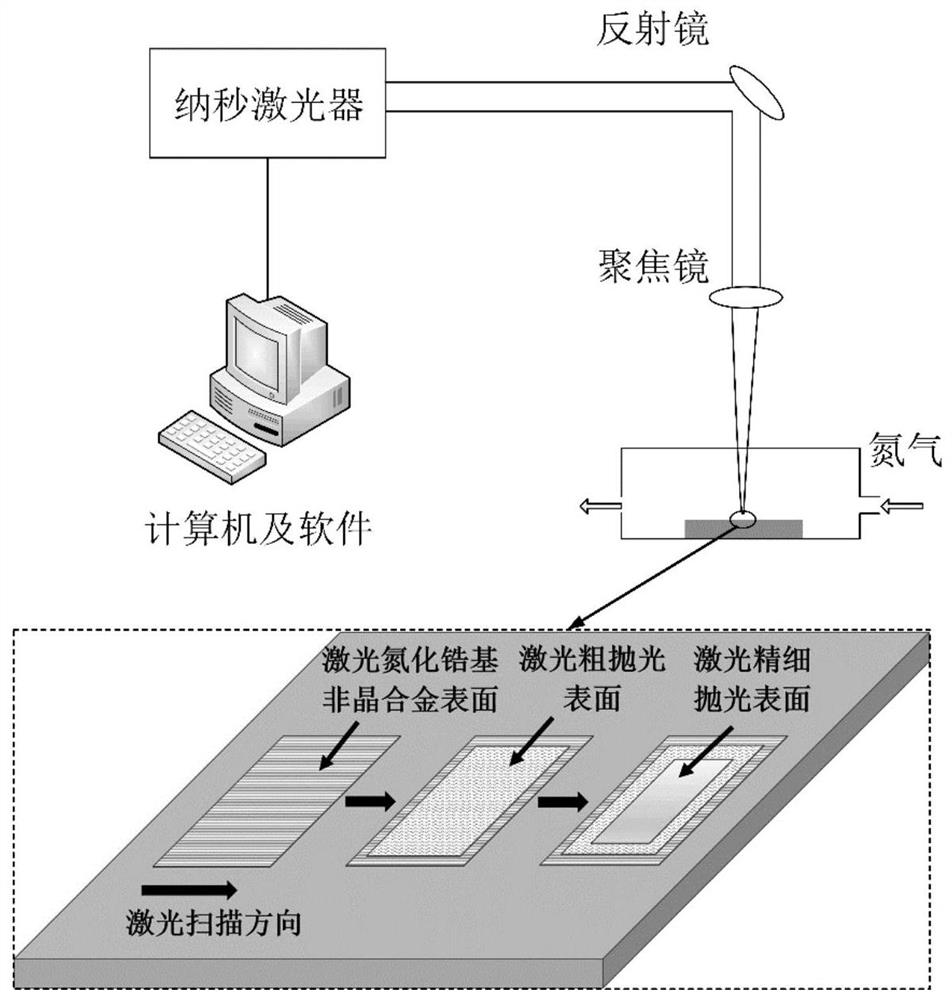

[0034] Taking a typical zirconium-based amorphous alloy (Zr41.2Ti13.8Cu12.5Ni10Be22.5) as an example, the laser nitrided surface was prepared in a nitrogen atmosphere, and then the nitrided surface was laser polished, and the following examples were used for further comparison The implementation process and beneficial effects of the present invention are described.

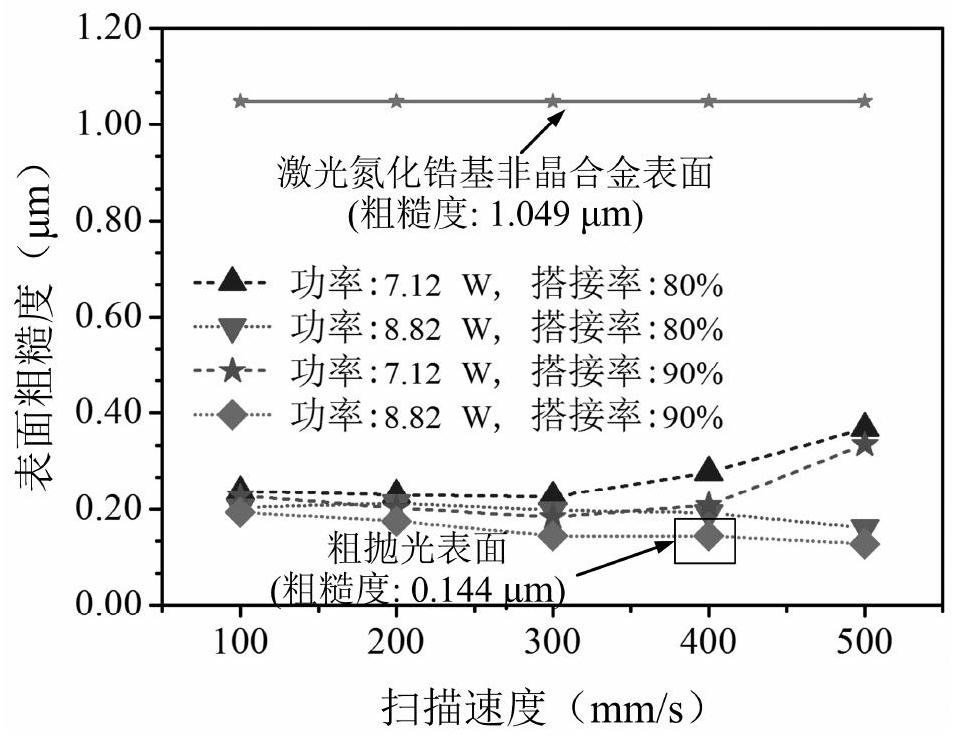

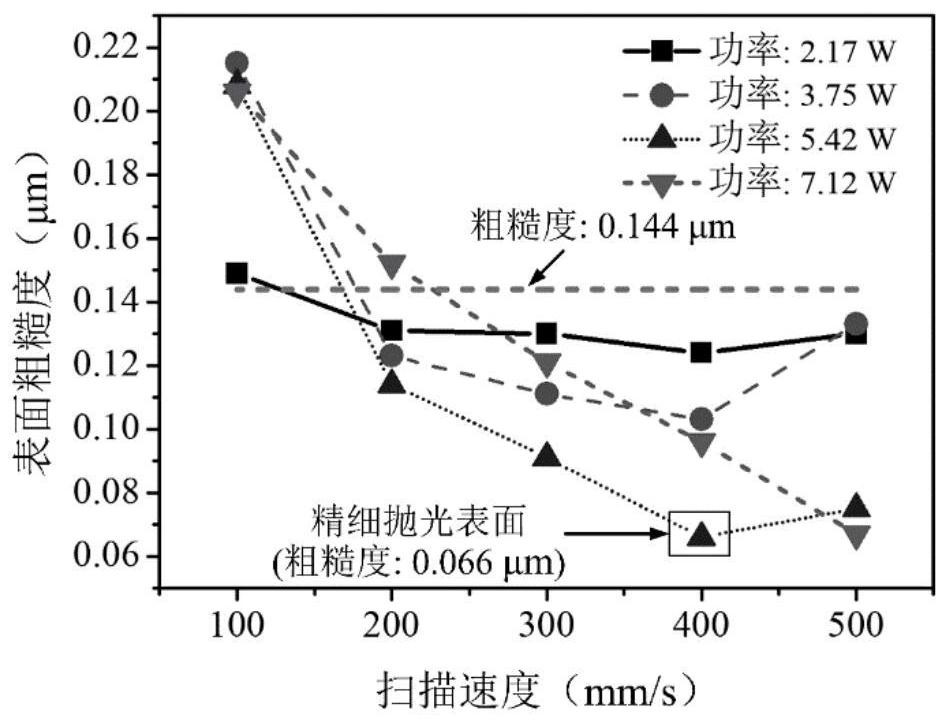

[0035] figure 2 When the average laser power is 7.12-8.82W, the scanning speed is 100-500mm / s, the overlapping rate of adjacent scanning lines is 80-90%, and the scanning is repeated once, after rough laser polishing is performed on the surface of the laser zirconium nitride-based amorphous alloy , the surface roughness value obtained by laser confocal, it can be seen that after rough laser polishing in a nitrogen atmosphere, the surface roughness is reduced by a maximum of 0.905 μm compared with the laser nitrided surface, which is 86.3%, indicating that the laser roughness in a nitrogen atmosphere Polishing ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com