Resin coating 3D printing method and system

A 3D printing and 3D technology, which is applied in the field of resin coating 3D printing methods and systems, can solve problems such as damaged samples, and achieve the effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

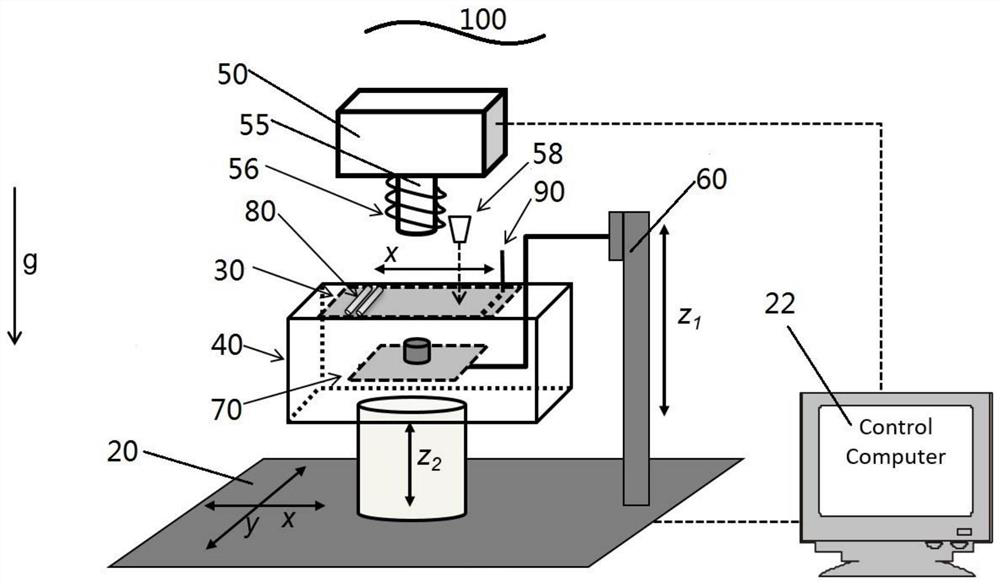

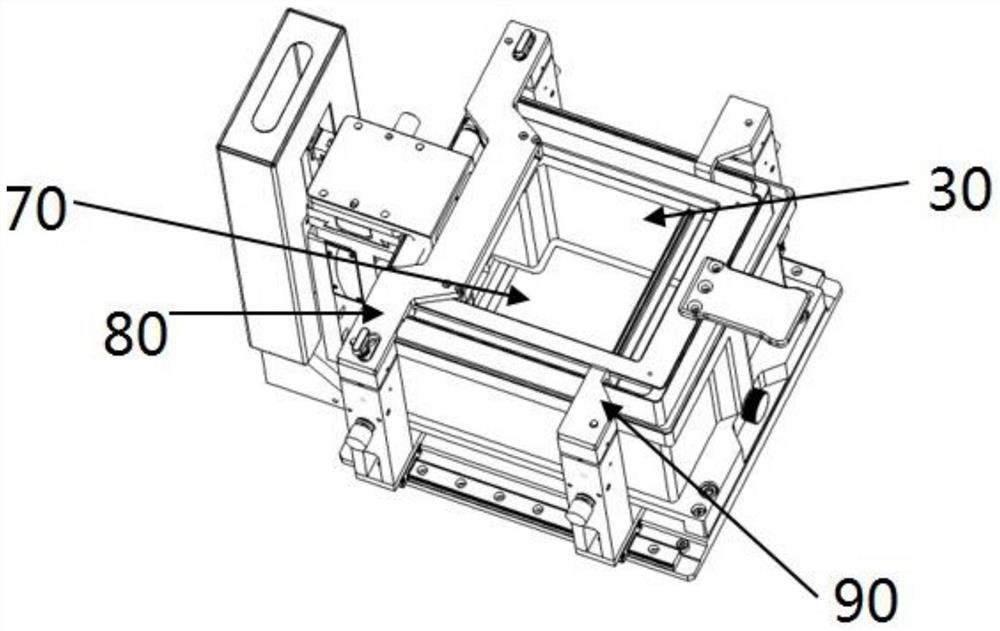

[0042] The 3D printing method of an embodiment of the present invention includes:

[0043] Slicing: generating a 3D digital model of the sample to be printed, cutting the 3D digital model into an image sequence, each image in the image sequence represents a layer of the 3D digital model, and controlling the printing direction according to the slice direction of the model;

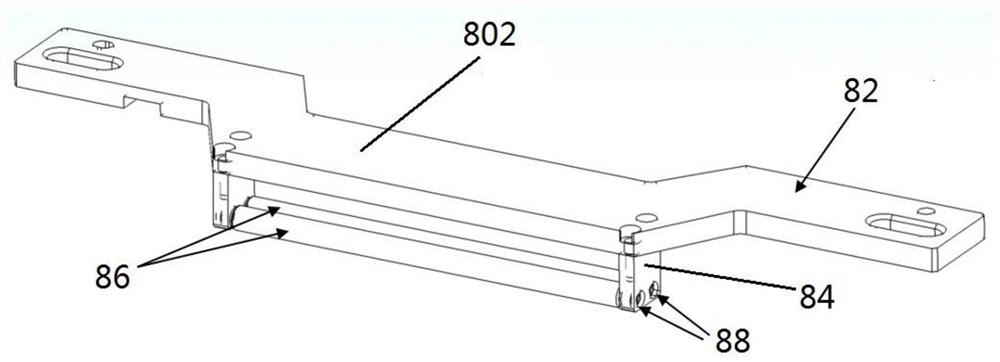

[0044] Projection: control to send the image to the exposure system, the exposure system projects the image onto the surface of the transparent film through the projection lens, the lower surface of the transparent film is in contact with the printing material, and the sample layer to be printed that is in contact with the transparent film is prepared;

[0045] Exposure printing: the exposure system drives light to irradiate the projected image, and the exposure produces a cured layer, which represents the corresponding layer of the projected image in the 3D digital model;

[0046] Continue exposure printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com