Energy-saving type sodium sulphite circulation desulfurizing device and method

A technology of sodium sulfite and desulfurization device, applied in the field of flue gas desulfurization, can solve the problem of insufficient utilization of flue gas waste heat, and achieve the effects of being beneficial to environmental protection, reducing operating costs, and ensuring process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

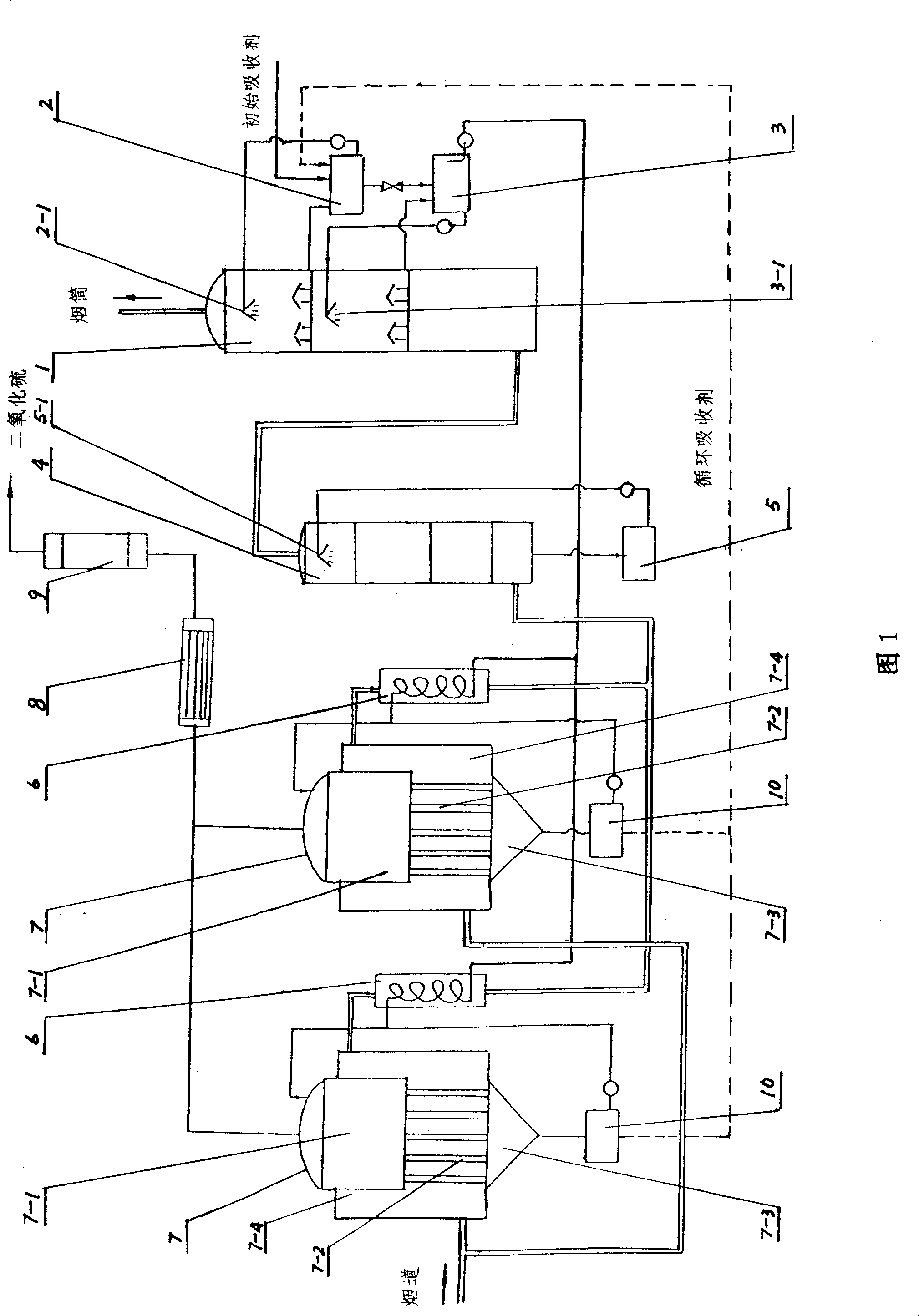

[0039] Embodiment 1: Sodium carbonate is used as the initial absorbent, and the flue gas is desulfurized by an energy-saving sodium sulfite circulating desulfurization device.

[0040] Referring to Figure 1, the interior of the desulfurization tower 1 of the energy-saving sodium sulfite circulating desulfurization device is divided into upper, middle and lower areas by two intervals, and the first absorption liquid circulation tank 2 and the second absorption liquid circulation tank 3 are located in the desulfurization tower outside, the bottom of the upper area of the desulfurization tower communicates with the first absorption liquid circulation tank, the bottom of the middle area of the desulfurization tower communicates with the second absorption liquid circulation tank, and the bottom of the first absorption liquid circulation tank communicates with the second absorption liquid circulation tank; The first nozzle 2-1 connected to the first absorption liquid circulation ...

Embodiment 2

[0059]Embodiment 2: Sodium carbonate is used as the initial absorbent, and the flue gas is desulfurized by an energy-saving sodium sulfite circulating desulfurization device.

[0060] The first step is to prepare the initial absorption solution: the initial absorption agent is Na 2 CO 3 , add soft water (deionized water) into the first absorption liquid circulation tank 2, and gradually add Na 2 CO 3 , so that the concentration by weight in the solution is 16%. After fully dissolving, add 0.05% of the solution weight antioxidant-p-phenylenediamine, and stir evenly; the rest of the steps are the same as in Example 1.

Embodiment 3

[0061] Embodiment 3: Sodium carbonate is used as the initial absorbent, and the flue gas is desulfurized by an energy-saving sodium sulfite circulating desulfurization device.

[0062] The first step is to prepare the initial absorption solution: the initial absorption agent is Na 2 CO 3 , add soft water (deionized water) into the first absorption liquid circulation tank 2, and gradually add Na 2 CO 3 , so that the concentration by weight in the solution is 18%. After fully dissolving, add 0.05% antioxidant-hydroquinone by solution weight and stir evenly; the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com