Extraction method of orange peel essential oil

A technology of citrus peel and extraction method, applied in the directions of essential oils/spices, fat generation, etc., can solve the problems of affecting the separation effect, reducing water viscosity, and deteriorating oil aroma, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

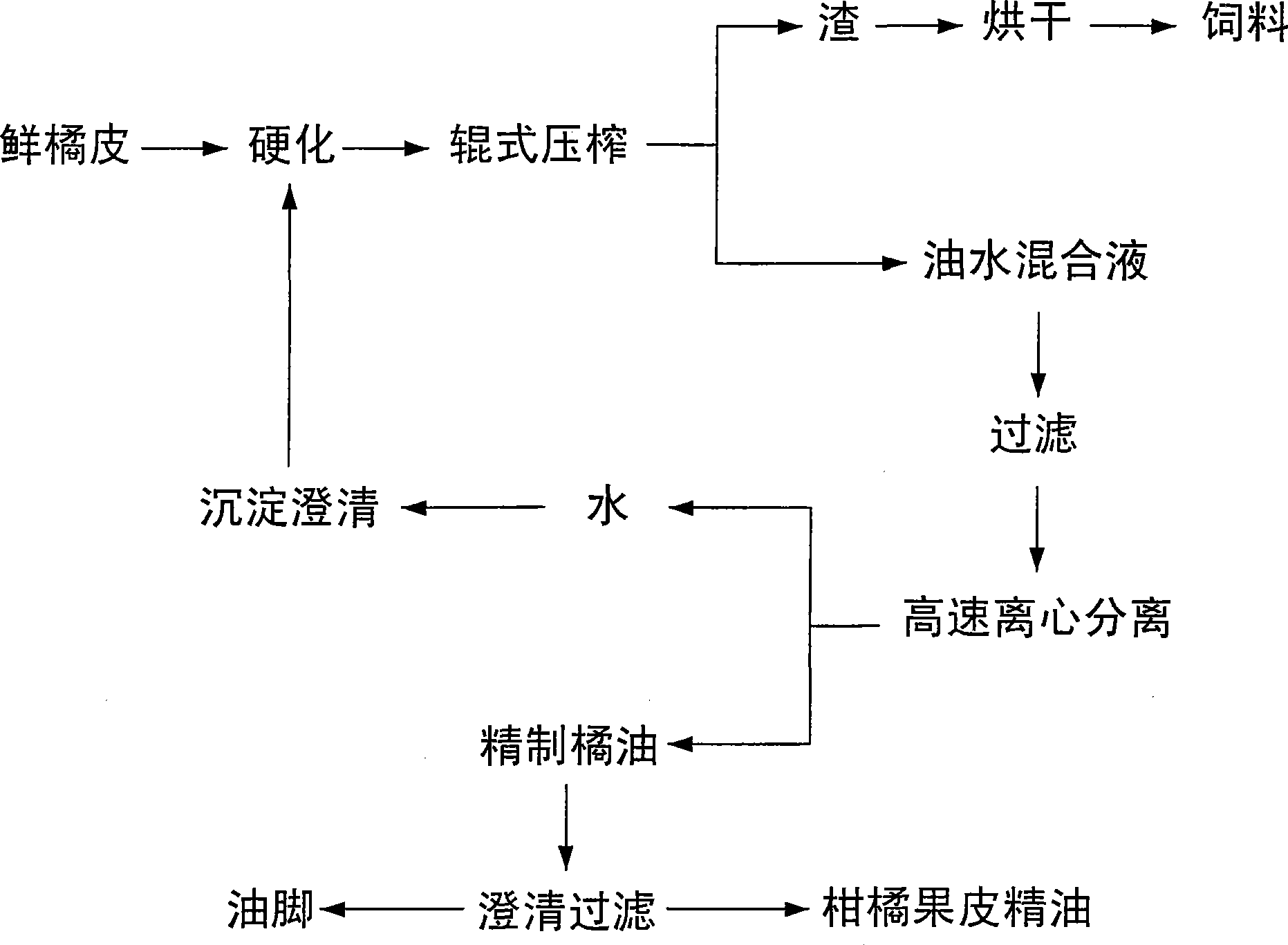

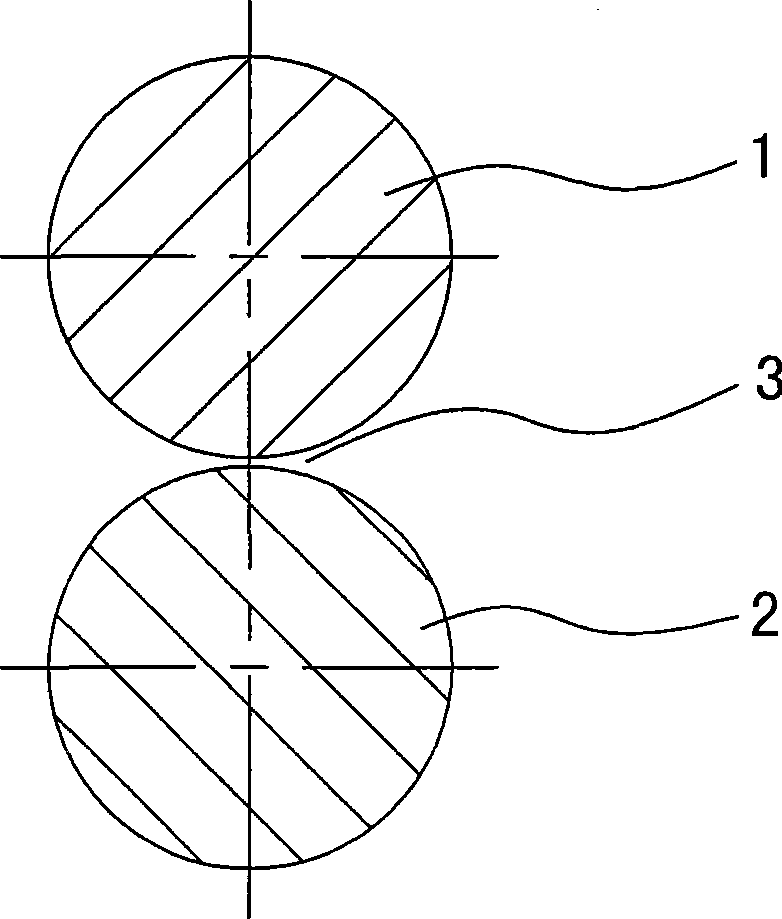

[0030] The extraction method of citrus peel essential oil of the present invention is characterized in that, in proportion by weight, 99.04% to 99.26% of water, 0.1% to 0.2% of sodium benzoate, 0.5% to 0.8% of anhydrous calcium chloride, and 0.04% to 0.06% of sodium bisulfite % prepare hardening solution; then take fresh orange peel and hardening solution according to the weight ratio and mix and soak for 2 to 3 hours in a ratio of 1:4. figure 2 , is a product example, upper roll 1, lower roll 2, feed channel 3, and the gap and pressure between the two rolls of the roll press can be adjusted mutually. In actual production, the roller press can adopt other structural types. The resulting orange peel is dried or used directly as animal feed. Squeeze the mixed solution of gained orange oil and water, filter through 80~120 mesh filter screens, then separate under 18000 rev / min~20000 rev / min rotating speeds with pipeline type high-speed centrifuge, gained orange oil is about 5 ℃ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com