Composite leather greasing agent and preparation method thereof

A kind of leather fatliquor, compound technology, applied in leather impregnation, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Problems such as poor grease performance, limited application, and low proportion of dialkyl phosphate esters can achieve the effects of excellent comprehensive fatliquoring performance, high active content and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

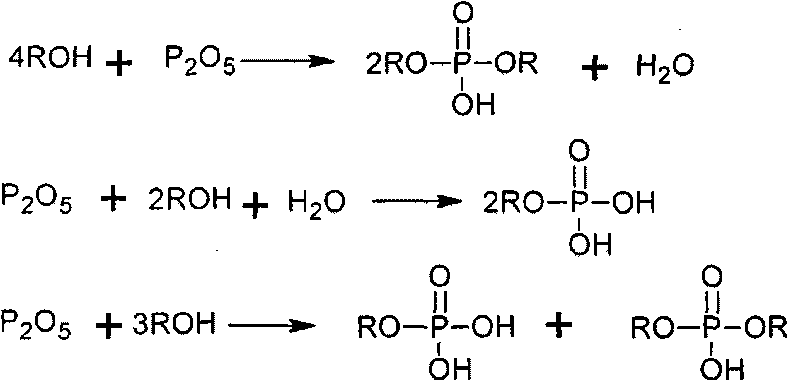

Method used

Image

Examples

Embodiment 1

[0019] Add 872g (1mol) of rapeseed oil into a four-necked flask with a reflux device, raise the temperature to 80°C, then add 67.1g (1.1mol) of monoethanolamine, 3.75g of sodium methoxide, and then raise the temperature to 130°C for 3 hours. After the reaction, the temperature was lowered to 120°C, the degree of vacuum was 0.02-0.05 MPa, and the vacuum was vacuumed for 30 minutes to remove unreacted monoethanolamine to obtain amidated rapeseed oil (hydroxyl value about 147 mg KOH / g).

Embodiment 2

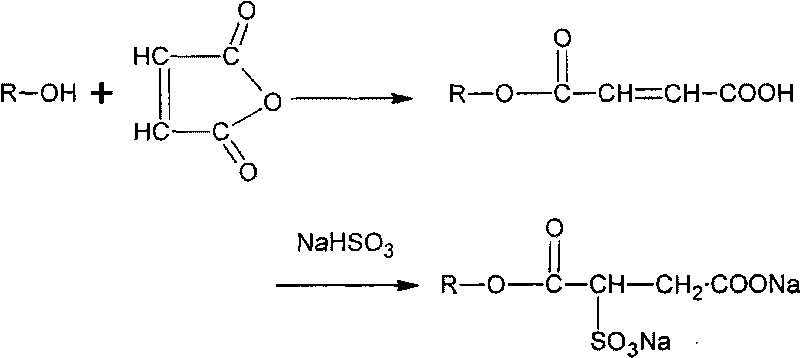

[0021] Add 114g of the amidated modified rapeseed oil prepared in Example 1 into a four-neck flask equipped with a reflux and temperature control device, raise the temperature to 60°C, add 3.55g of phosphorus pentoxide, then raise the temperature to 80°C, and keep the temperature for 2 hours. After the heat preservation is over, lower the temperature to 70°C, add 19.6g of maleic anhydride, then raise the temperature to 90°C, and keep the temperature for 2.5 hours. , adjust the pH of the reactant to 6.5-7.5, then add aqueous sodium bisulfite solution (21.84g sodium bisulfite dissolved in 90.69g deionized water), heat up to 80°C after the addition, and keep the temperature for 2 hours to obtain the effective substance mass fraction About 55% compound leather fatliquor.

[0022] Example 2

[0023] Add 114g of the amidated modified rapeseed oil prepared in Example 1 into a four-neck flask equipped with a reflux and temperature control device, raise the temperature to 60°C, add 5....

Embodiment 3

[0025] Add 152g of the amidated modified rapeseed oil prepared in Example 1 into a four-neck flask with a reflux and temperature control device, raise the temperature to 60°C, add 3.55g of phosphorus pentoxide, then raise the temperature to 80°C, and keep the temperature for 2 hours. After the heat preservation is over, lower the temperature to 70°C, add 29.4g of maleic anhydride, then raise the temperature to 90°C, and keep the temperature for 2.5 hours. , adjust the pH of the reactant to 6.5-7.5, then add an aqueous solution of sodium bisulfite (32.76g of sodium bisulfite dissolved in 145g of deionized water), heat up to 80°C after the addition, and keep the reaction for 2 hours to obtain an effective substance mass fraction of about 55% compound leather fatliquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com