Lost circulation material for malignant loss and preparation method

A plugging agent and vicious technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult to condense and solidify, difficult for plugging materials to stay near the entrance of the leakage layer, and large leakage volume, etc., to achieve durable The effect of strong temperature resistance to salinity, excellent shear thinning performance, and strong anti-washing thinning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: the preparation method of this leakage stoppage agent:

[0011] First recrystallize acrylamide and sodium dodecylbenzenesulfonate with acetone, and recrystallize hexadecyldimethylallyl ammonium chloride with ethyl acetate; first add the recrystallized After 10 grams of hexadecyldimethylallyl ammonium chloride, 17 grams of acrylamide and 9 grams of sodium styrene sulfate, dissolve completely with 160 grams of fresh water, and adjust the pH value of the system to 6.5 with NaOH solution; Introduce nitrogen into the container for 30 minutes, add 0.2 g of initiator potassium persulfate / sodium bisulfite, continue to ventilate nitrogen for 10 minutes, seal it, place it in an incubator at a constant temperature of 40°C, and react for 24 hours; take it out and cool it to room temperature, and precipitate with acetone , repeatedly washed with acetone solution for 3 times, crushed into fine particles, then soaked in acetone for one day, and dried in vacuum at 40°C to...

Embodiment 2

[0012] Example 2: The degree of flushing of the plugging agent is measured by the sieve method, and the experiment proves that the invention has good anti-flushing ability

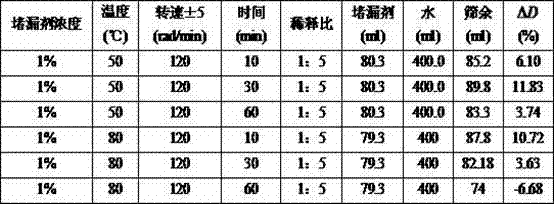

[0013] Table 1 Test results of anti-flushing ability of this lost circulation plugging agent

[0014]

[0015] It is measured by diluting degree of the plugging agent at different temperatures and different concentrations. It is found that the plugging agent with a concentration of 1% still has a strong anti-flushing ability at high temperature.

Embodiment 3

[0016] Embodiment 3: The present invention has a good retention capacity and can effectively reside near the entrance of the leakage layer of large cracks;

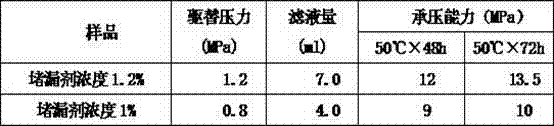

[0017] The retention capacity is to evaluate the network retention performance of the plugging agent in the formation;

[0018] The measurement method is: pour the prepared plugging agent into a core holder equipped with a simulated large crack (the width of the simulated crack is 3 mm), and place a layer of 10-mesh screen on the lower end of the steel cylinder (to simulate a large leak). Put the core holder into a high-temperature oven, increase the ring pressure to 3MPa, turn on the advection pump, simulate the on-site congestion conditions, displace 10ml (1PV) of clean water, and measure the displacement pump pressure and the filtrate volume at the outlet

[0019] Table 2 The results of the residence ability test

[0020]

[0021] It can be seen from the experimental data that after the lost circulation plugging ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com