Plugging agent, preparation method and application thereof, and drilling fluid

A plugging agent and reaction technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low strength, insufficient rigidity of the plugging layer, insufficient retention performance of the plugging formation, etc., and achieve particle size matching. Good effect, improved temperature resistance, good lipophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

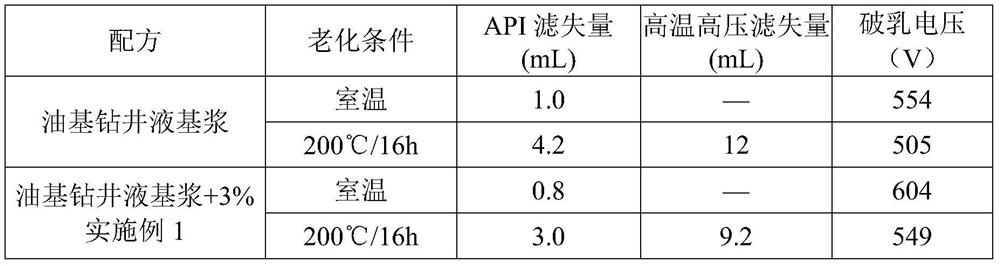

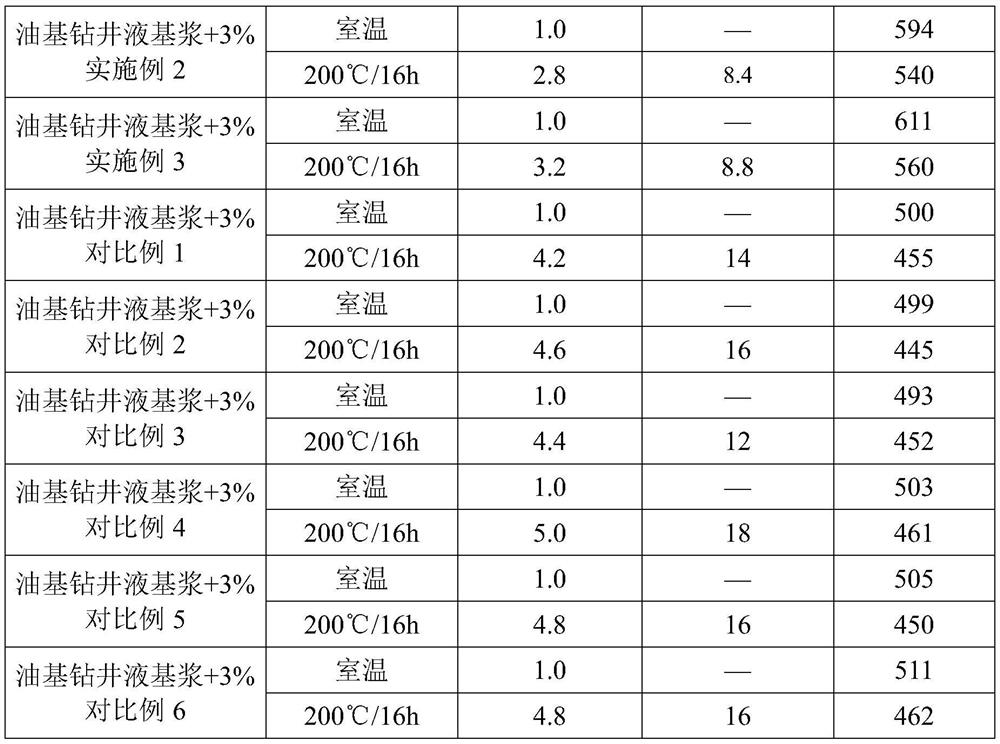

Examples

Embodiment 1

[0045] This embodiment provides a lost circulation agent, which can be used as a lost circulation agent while drilling for high temperature resistant oil-based drilling fluid. The preparation method of this leakage stoppage agent comprises:

[0046] 1. Add 6 g of methacrylic acid, 4 g of acrylamide, and 10 g of 2-(methacryloxy)ethyltrimethylammonium chloride into 200 mL of deionized water, and stir at a stirring rate of 400 r / min for 10 min to obtain a mixed solution .

[0047] 2. Keep the mixture stirred at a stirring rate of 400r / min, add 20g of dimethylaminoethyl methacrylate, 15g of hydroxyethyl methacrylate, 10g of sodium p-styrenesulfonate, 10g of sodium 4-hydroxybenzenesulfonate, Add 2g of emulsifier MS-1 into the mixture, and continue to stir for 20min at a stirring rate of 400r / min to obtain a pre-emulsion.

[0048] 3. Take 1 / 2 of the pre-emulsion and add it to a four-necked flask equipped with a stirrer, a condenser, and a dropping funnel, and pass nitrogen gas for...

Embodiment 2

[0050] This embodiment provides a lost circulation agent, which can be used as a lost circulation agent while drilling for high temperature resistant oil-based drilling fluid. The preparation method of this leakage stoppage agent comprises:

[0051] 1. Add 5 g of acrylic acid, 5 g of caprolactam, and 8 g of dimethyldiallyl ammonium chloride into 200 mL of deionized water, and stir at a stirring rate of 400 r / min for 10 min to obtain a mixed solution.

[0052] 2. Keep the mixed solution stirring at a stirring rate of 400r / min, add 20g of butyl acrylate, 10g of methyl methacrylate, 10g of styrene, 8g of N-vinylpyrrolidone, and 2g of emulsifier MS-1 into the mixed solution, and stir at 400r / min / min stirring rate and continue to stir for 20min to obtain a pre-emulsion.

[0053] 3. Take 1 / 2 of the pre-emulsion and add it to a four-necked flask equipped with a stirrer, a condenser, and a dropping funnel, and pass nitrogen gas for 20 minutes. After the temperature is raised to 60°C...

Embodiment 3

[0055] This embodiment provides a lost circulation agent, which can be used as a lost circulation agent while drilling for high temperature resistant oil-based drilling fluid. The preparation method of this leakage stoppage agent comprises:

[0056] 1. Mix 5g of acrylic acid, 5g of acrylamide, 4g of 2-acrylamido-2-methylpropanesulfonic acid, 5g of 2-(methacryloyloxy)ethyltrimethylammonium chloride, dimethyldiene 5 g of propylammonium chloride was added into 200 mL of deionized water, and stirred at a stirring rate of 400 r / min for 10 min to obtain a mixed solution.

[0057] 2. Keep the mixed liquid stirring at a stirring rate of 400r / min, add 20g of butyl acrylate, 20g of dimethylaminoethyl methacrylate, 10g of sodium p-styrenesulfonate, 10g of N-vinylpyrrolidone, 2g of emulsifier MS- 1 into the mixed solution and continue to stir for 20 min at a stirring rate of 400r / min to obtain a pre-emulsion.

[0058] 3. Take 1 / 2 of the pre-emulsion and add it to a four-necked flask equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com