Evaluation Method of Corrosion Condition of Steel-cored Aluminum Stranded Aerial Conductor

A technology for overhead wires and evaluation methods, which is applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., and can solve problems such as prediction of remaining life without evaluation of corrosion status of overhead wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

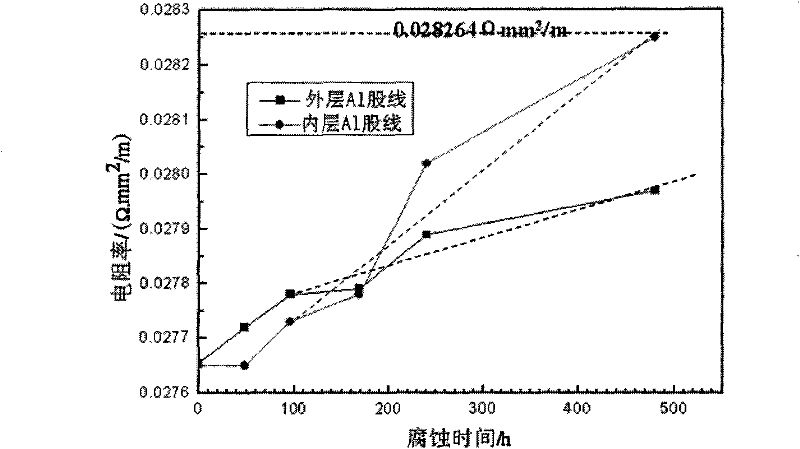

[0016] Evaluation of the corrosion of steel-cored aluminum stranded conductors in coastal areas simulated by sodium chloride (NaCl) salt spray

[0017] (1) Solution preparation: Use chemically pure sodium chloride (NaCl) to prepare a 45-55g / L sodium chloride (NaCl) deionized aqueous solution, with a pH of 6.5-7.2.

[0018] (2) Test conditions and working parameters: YWX / F-250E salt spray test chamber, the temperature of the test chamber is 35±2℃, and the sedimentation volume is 1-2mL / 80cm 2 ·H. The intermittent spray corrosion method is adopted, every 8 hours of continuous spraying, the machine is stopped, the sample is taken out of the salt spray box, and it is naturally dried in the laboratory for 16 hours to complete a dry / wet corrosion test cycle (24h).

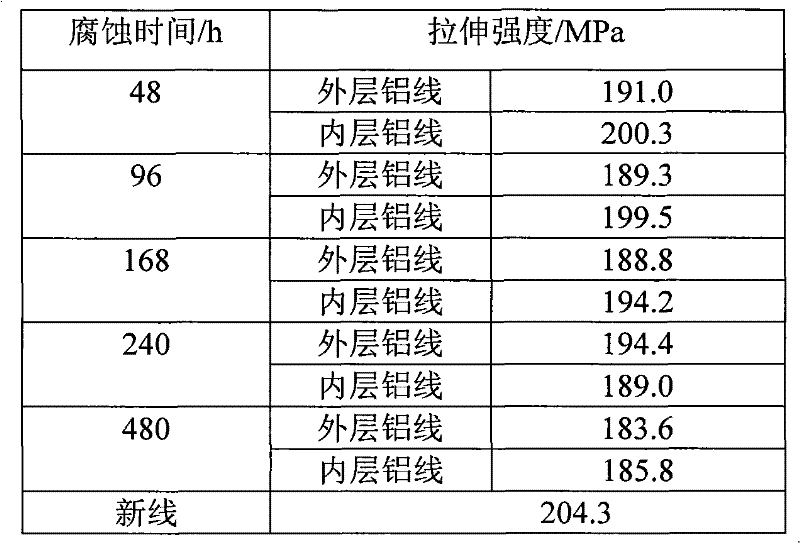

[0019] (3) Test period: 48-480h. Take out samples from the test box at regular intervals for testing.

[0020] (4) Type of overhead wire: LGJ150 / 25 steel core aluminum stranded wire.

[0021] (5) Tensile mechanical performance te...

Embodiment 2

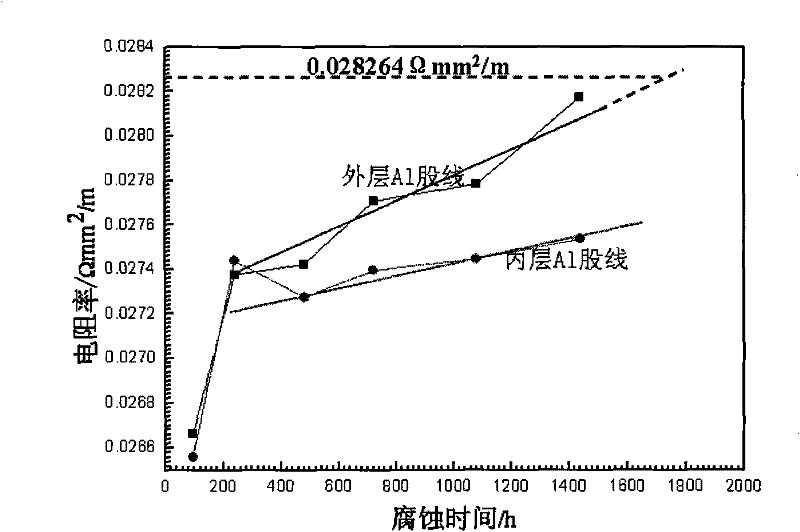

[0028] Sodium bisulfite + sodium chloride (NaHSO 3 +NaCl) Evaluation of corrosion status of steel-cored aluminum-stranded wires in simulated industrial pollution areas with salt spray

[0029] (1) Solution preparation: use chemical pure sodium bisulfite (NaHSO 3 ) And sodium chloride (NaCl) to prepare sodium bisulfite (NaHSO 3 )+sodium chloride (NaCl) aqueous solution (concentration: 10.4g / L sodium bisulfite (NaHSO) 3 ), 0.59g / L sodium chloride (NaCl), pH value is 4.5-5.0).

[0030] (2) Test conditions and working parameters: YWX / F-250E salt spray test chamber, the temperature of the test chamber is 35±2℃, and the sedimentation volume is 1-2mL / 80cm 2 ·H. The intermittent spray corrosion method is adopted, every 8 hours of continuous spraying, the machine is stopped, the sample is taken out of the salt spray box, and it is naturally dried in the laboratory for 16 hours to complete a dry / wet corrosion test cycle (24h).

[0031] (3) Test period: 96-1440h. Take out samples from the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com