Gas coal hydrofracture field time-space monitoring device and method

A hydraulic fracturing and monitoring device technology, applied in the direction of material resistance, etc., can solve the problems of increased construction cost, inability to realize the comprehensive evolution of coal and rock mass structure, continuous evaluation of time and space, and impact on coal mine safety production, etc., to achieve low production cost, Good airtightness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

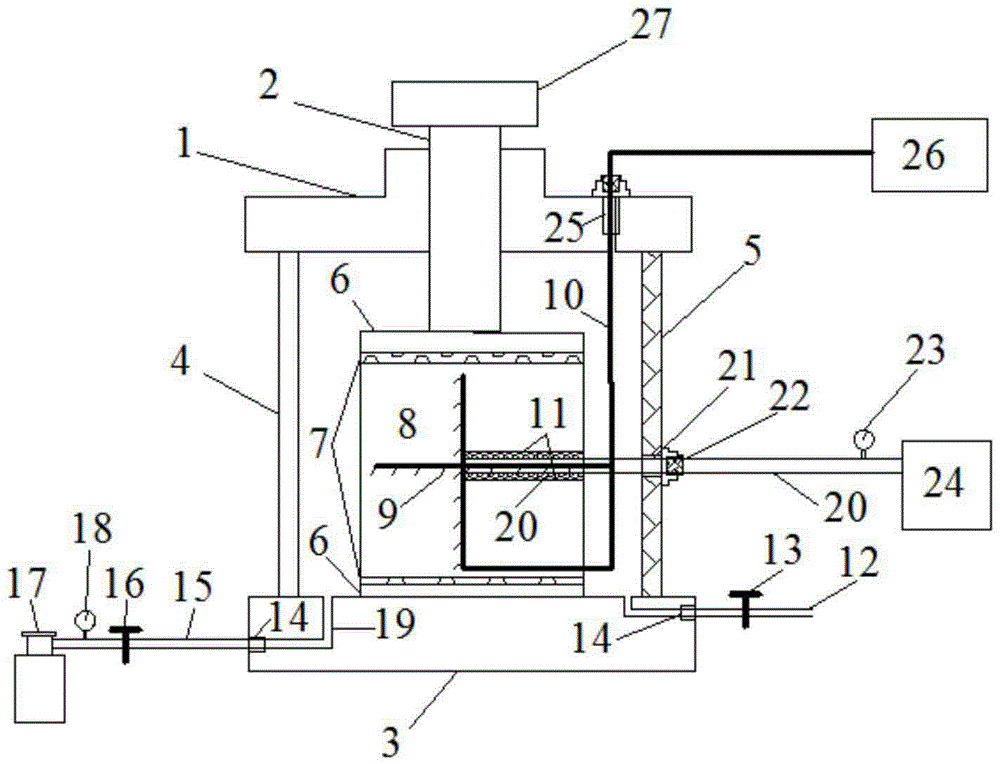

[0040] like figure 1 As shown, the gas-coal hydraulic fracturing fracture field space-time monitoring device of the present invention is composed of a main cavity, an in-situ stress simulation module, a gas filling and discharging module, a hydraulic fracturing module and a resistivity testing module. The main cavity includes a base 3, a square cylinder disposed on the base 3 and an upper cover 1 disposed on the square cylinder. The front, rear and left sides of the square cylinder are observable hydraulic fracturing surfaces. The plexiglass 4 of the real-time fracture evolution process on the surface of the coal sample 8, the right side is the steel plate 5 with the guide hole 21, the base 3 is provided with a left channel and a right channel leading to the cylinder body, and the left channel and the right channel entrance There are sealing bolts 14 respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com