Preparation method of anion sulfonate type coal water slurry dispersant

An anionic sulfonate and coal-water slurry technology, which is applied in liquid carbon-containing fuels, petroleum industry, fuels, etc., can solve the problems of poor fluidity of coal slurry and poor stability of coal slurry, and achieve excellent dispersion and stabilization , not easy to gel, good fluidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

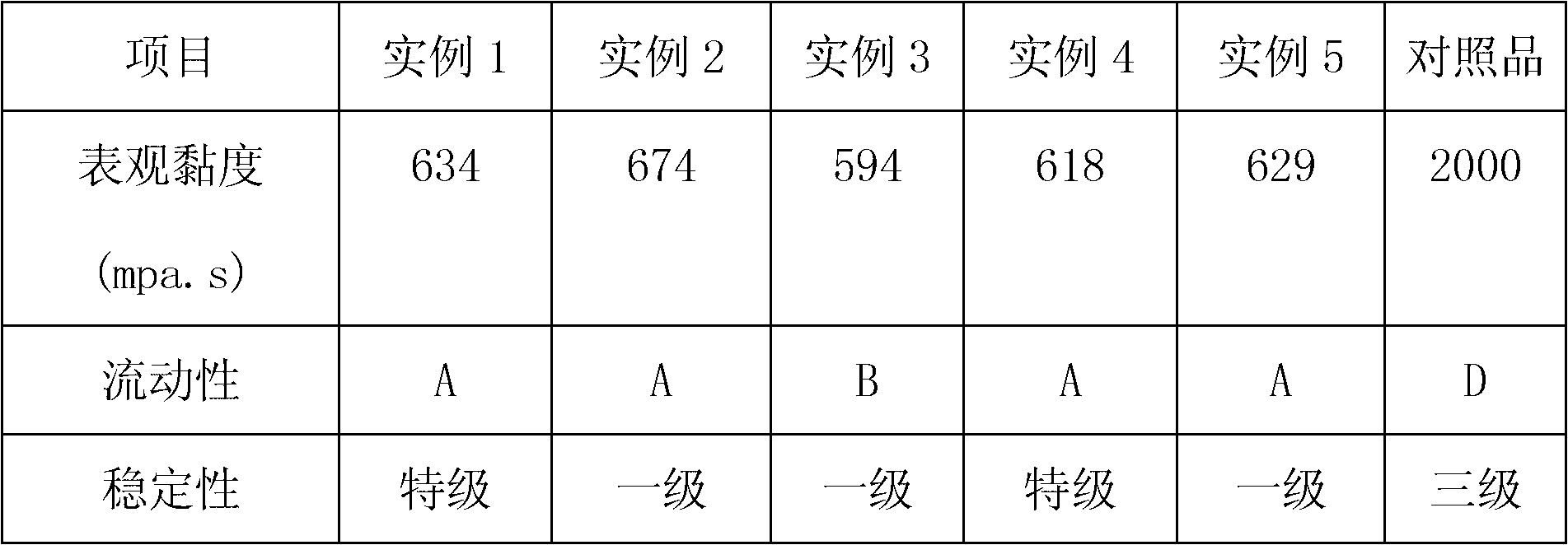

Examples

Embodiment 1

[0021] 1) First, mix acrylic acid (AA), itaconic acid (IA) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) according to the mass ratio of AA:IA:AMPS=5:2:10, and then Add water and stir evenly to obtain a terpolymer with a solid content of 20%; 2) Next, use sodium hypophosphite as a chain transfer agent, and add the chain transfer agent to the terpolymer in an amount of AA, 5% of the total mass of IA and AMPS; 3) Then, add 0.5% of the total mass of AA, IA and AMPS to the initiator of the terpolymer, and stir to obtain a mixture. The initiator is ammonium persulfate; 4) Finally, The mixture was reacted in a water bath at 80° C. for 4 hours, then cooled to room temperature, and then the pH was adjusted to 9 to obtain an anionic sulfonate-type terpolymer coal-water slurry dispersant.

Embodiment 2

[0023] 1) First, mix acrylic acid (AA), itaconic acid (IA) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) according to the mass ratio of AA:IA:AMPS=5:2:10, and then Add water and stir evenly to obtain a terpolymer with a solid content of 40%; 2) Next, use sodium hypophosphite as a chain transfer agent, and add the chain transfer agent to the terpolymer in an amount of AA, 7% of the total mass of IA and AMPS; 3) Then, add 0.7% of the total mass of AA, IA and AMPS to the terpolymer and stir to obtain a mixture. The initiator is potassium persulfate; 4) Finally, The mixture was reacted in a water bath at 85° C. for 5 hours, then cooled to room temperature, and then the pH was adjusted to 10 to obtain an anionic sulfonate-type terpolymer coal-water slurry dispersant.

Embodiment 3

[0025] 1) First, mix acrylic acid (AA), itaconic acid (IA) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) according to the mass ratio of AA:IA:AMPS=5:2:10, and then Add water and stir evenly to obtain a terpolymer with a solid content of 25%; 2) Next, use sodium hypophosphite as a chain transfer agent, and add the chain transfer agent to the terpolymer in an amount of AA, 15% of the total mass of IA and AMPS; 3) Then, add AA, IA and an initiator of 1.0% of the total mass of AMPS to the terpolymer, and stir to obtain a mixture. The initiator is potassium persulfate-sodium sulfite, persulfuric acid The mass ratio of potassium: sodium sulfite = 2:1; 4) Finally, the mixture was reacted in a water bath at 90°C for 4 hours, cooled to room temperature, and then adjusted to pH 10 to obtain an anionic sulfonate terpolymer coal water slurry Dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com