Coal-water fluid gasifying spray nozzle

A technology of coal water slurry and nozzle, which is applied in the direction of combustion method, block/powder supply/distribution, liquid fuel supply/distribution, etc., which can solve the problem of poor load adjustability, reduced service life of refractory bricks, and change of nozzle atomization angle Larger problems, to achieve the effect of large load adjustment range, convenient installation and disassembly, flexible and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with the embodiment shown in accompanying drawing, this patent will be further described:

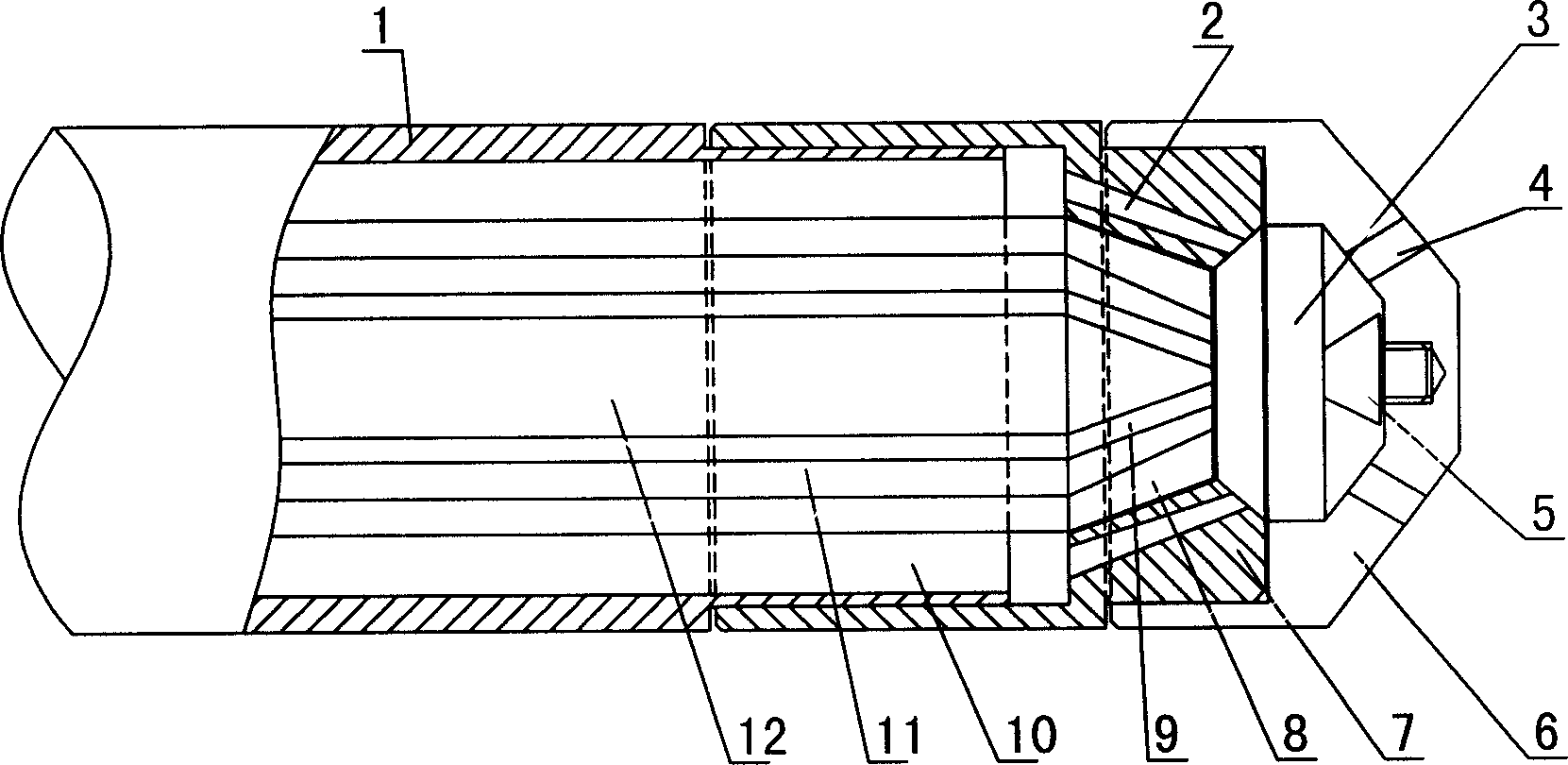

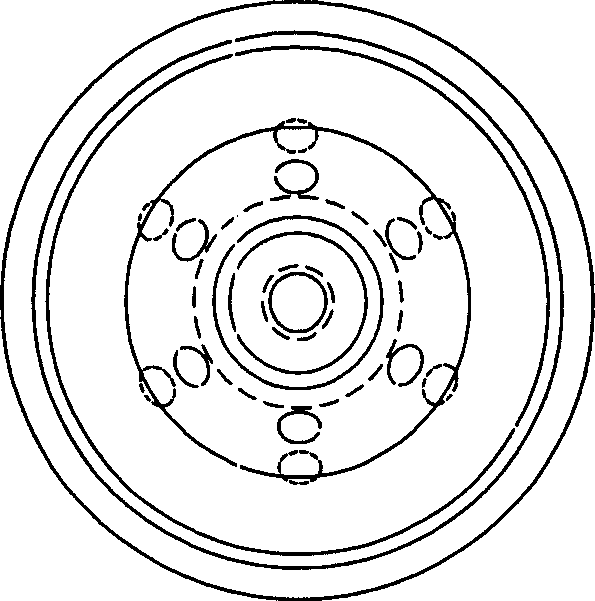

[0014] As shown in the figure, the coal-water slurry gasification nozzle of the present invention includes an outer sleeve 1, a central pipe oxidant channel 12, a middle-ring coal-water slurry channel 11 outside the central pipe, an outer-ring oxidant channel 10 outside the middle ring, three The cross-section of the channel is composed of a circular tubular structure with the same circle center; the central tube nozzle 9 connected with the central tube channel, the middle ring tube nozzle 8 connected with the middle ring channel, and the outer ring tube nozzle 7 connected with the outer ring channel; The mixing chamber 3 shoots out from the evenly arranged nozzle holes 4 on the atomizing head 6 after being fully impacted and broken, forming a high-speed atomizing airflow. The end of the central pipe oxidant channel 12 has a tapered tapered structure, forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com