Coal-water abrasion and corrosion resistant steel plate for railway coal transport vehicle and manufacturing method thereof

A manufacturing method and coal-water technology are applied in the field of process manufacturing of hot-rolled steel sheets, which can solve problems such as insufficient corrosion resistance, and achieve the effects of improving service life, obvious competitive advantages and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

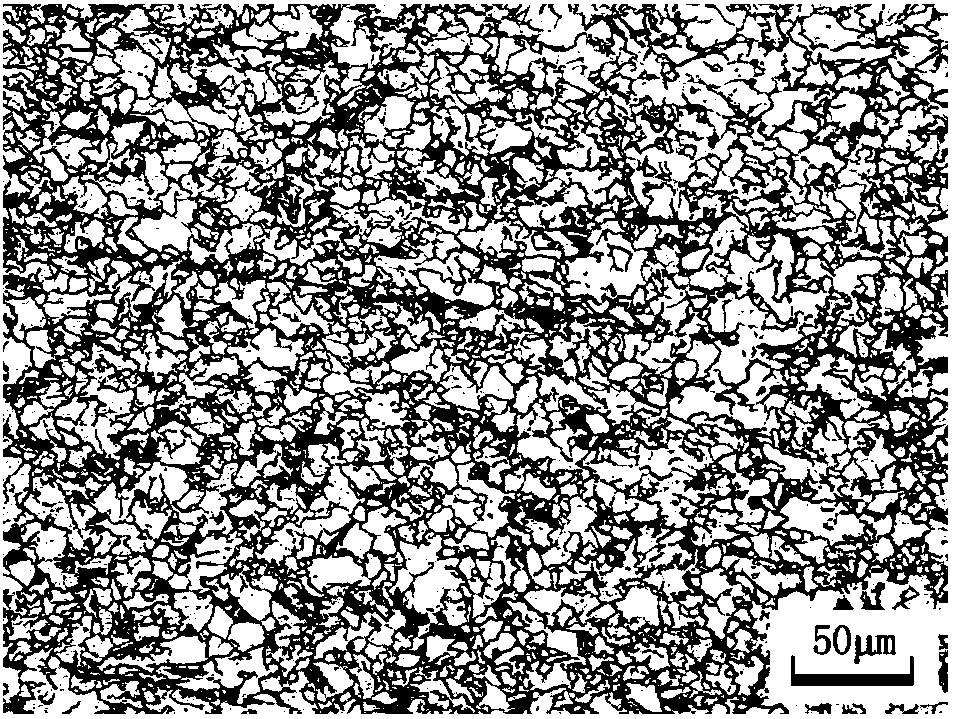

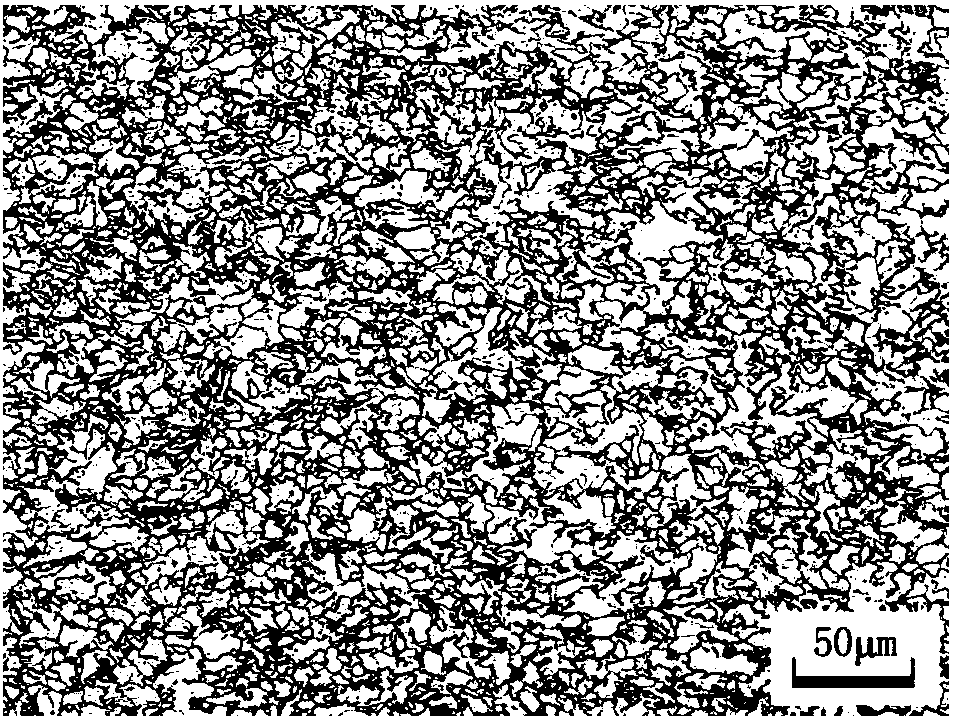

Image

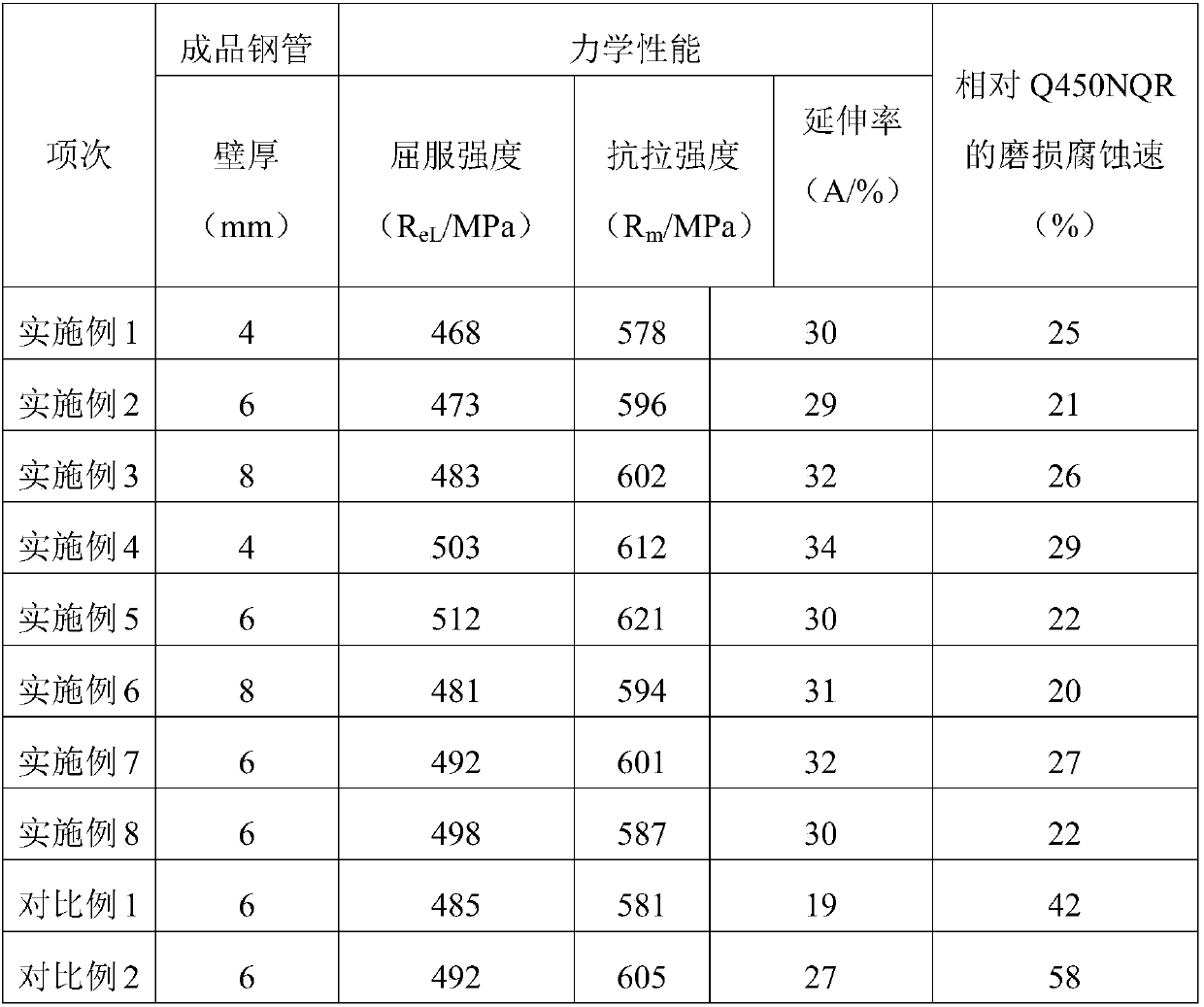

Examples

Embodiment 1

[0036] The chemical composition of the coal-water wear-resistant steel plate is shown in Table 1. After smelting according to the chemical composition shown in Table 1, the continuously cast slab or steel ingot was heated to 1217°C, the finishing temperature of rough rolling was 1080°C, the finishing rolling temperature was 890°C, the cooling rate was 15°C / s, and the coiling temperature was 700°C.

Embodiment 2

[0038] The implementation method is as in Example 1, wherein the continuous casting slab or steel ingot is heated to 1226°C after smelting, the finishing temperature of rough rolling is 1070°C, the finishing rolling temperature is 880°C, the cooling rate is 25°C / s, and the coiling temperature is 680°C.

Embodiment 3

[0040] The implementation method is as in Example 1, wherein the continuous casting slab or ingot is heated to 1231°C after smelting, the finishing temperature of rough rolling is 1060°C, the finishing rolling temperature is 870°C, the cooling rate is 31°C / s, and the coiling temperature is 670°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com