Combustion nozzle combination device of multi-channel coal water slurry gasification furnace

A combined device and coal-water slurry technology, which is applied in the direction of granular/powdered fuel gasification, can solve problems such as harsh construction and working conditions, bulky preheating burners, gas and oxygen leakage, etc., to improve operational safety and Reliability, control logic is clear, simple and reliable, and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

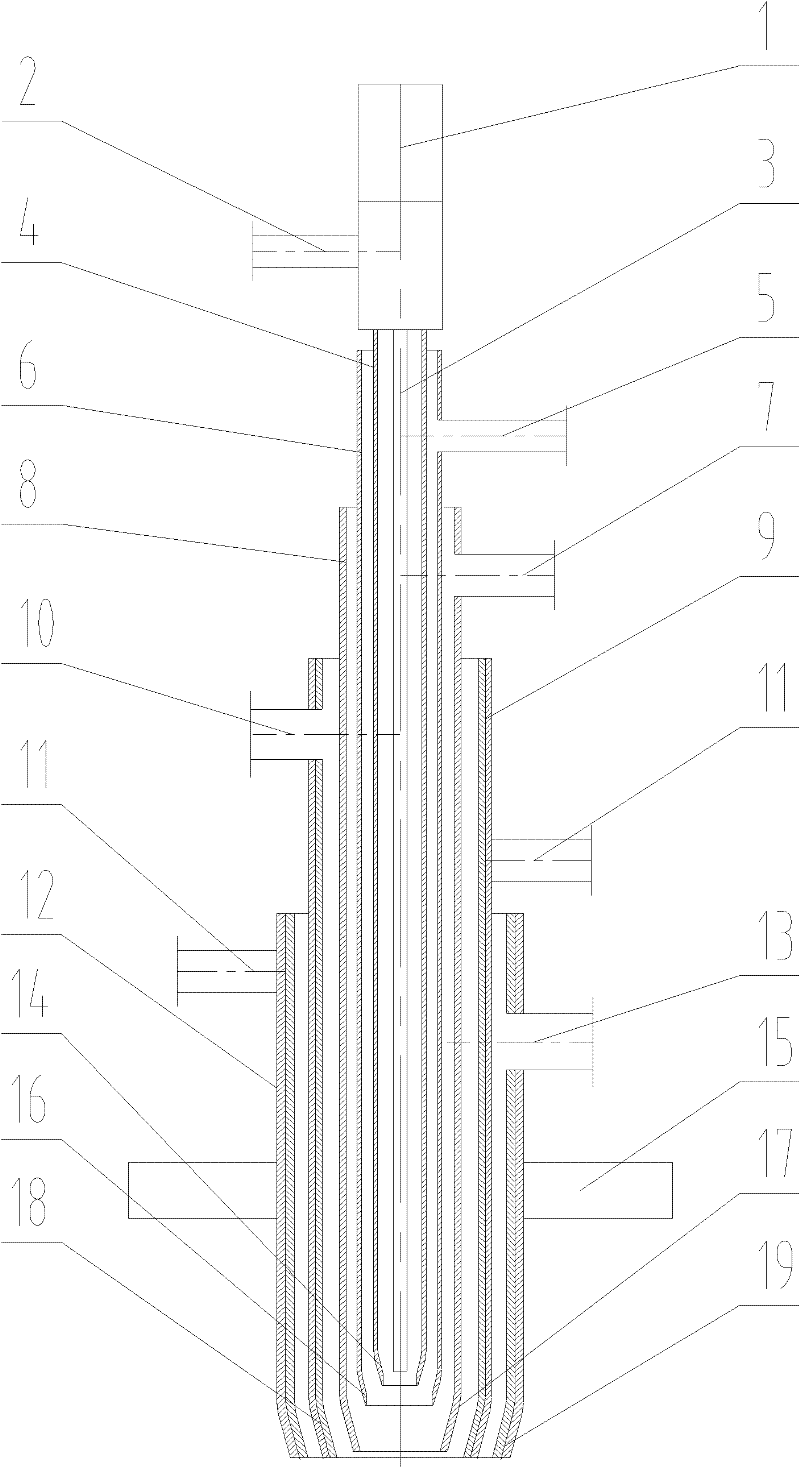

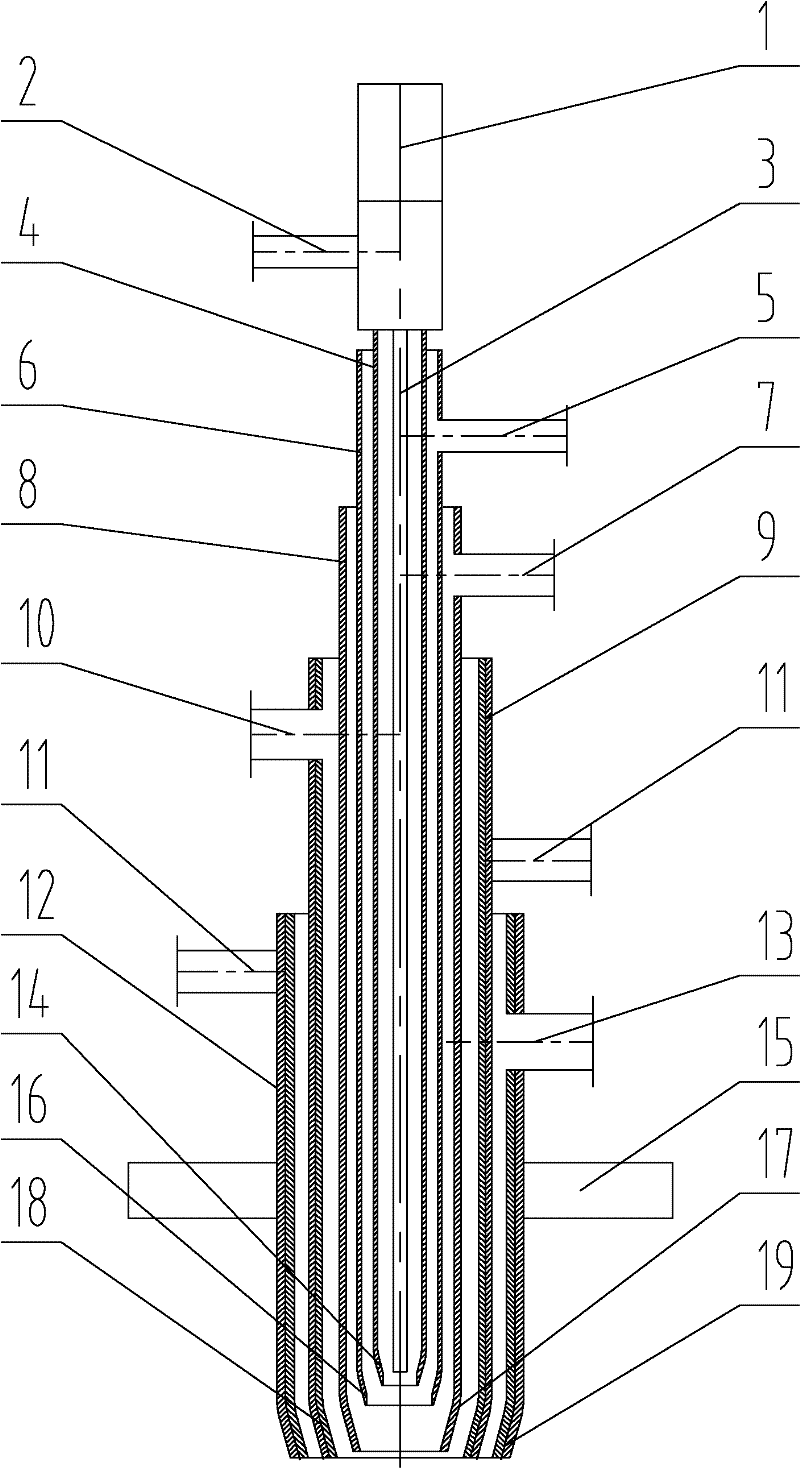

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] Such as figure 1 As shown, the high-voltage electric igniter 1 is connected to the electric ignition rod 3, the entire electric ignition rod 3 is installed in the ignition gas pipe 4, the ignition nozzle 14 is installed at the lower end of the ignition gas pipe 4, and the high-voltage electric igniter 1 is connected to the ignition fuel gas channel 2.

[0015] The ignition gas pipe 4 is wrapped with a central oxygen pipe 6 , a central oxygen nozzle 16 is installed at the lower end of the central oxygen pipe 6 , and one side of the central oxygen pipe 6 is connected to the central oxygen channel 5 .

[0016] The central oxygen pipe 6 and the central oxygen nozzle 16 are wrapped with a coal water slurry pipe 8, the lower end of the coal water slurry pipe 8 is equipped with a coal water slurry nozzle 17, and one side of the coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com