Method for exploiting coal-bed methane by utilizing water force of horizontal pinnate well of double well-shaft to scour, drill and relieve pressure

A coalbed methane and well hydraulic technology, which is applied in the field of coalbed methane mining by hydraulic flushing and pressure relief in double shaft horizontal pinnate wells, can solve problems such as blockage, difficulty in maintaining pressure relief space, easy collapse, blockage, etc. Increased pressure relief space, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with an embodiment (accompanying drawing):

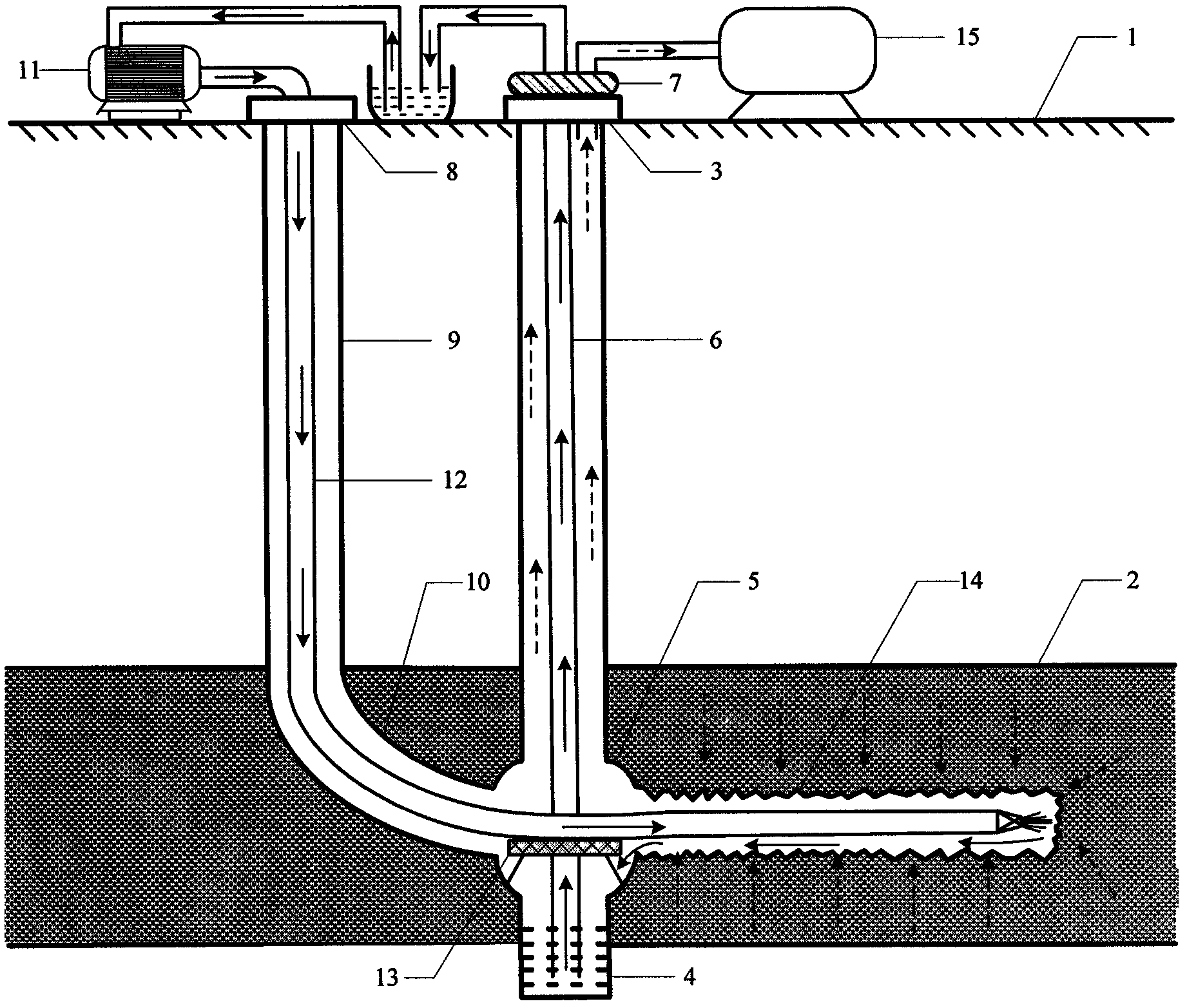

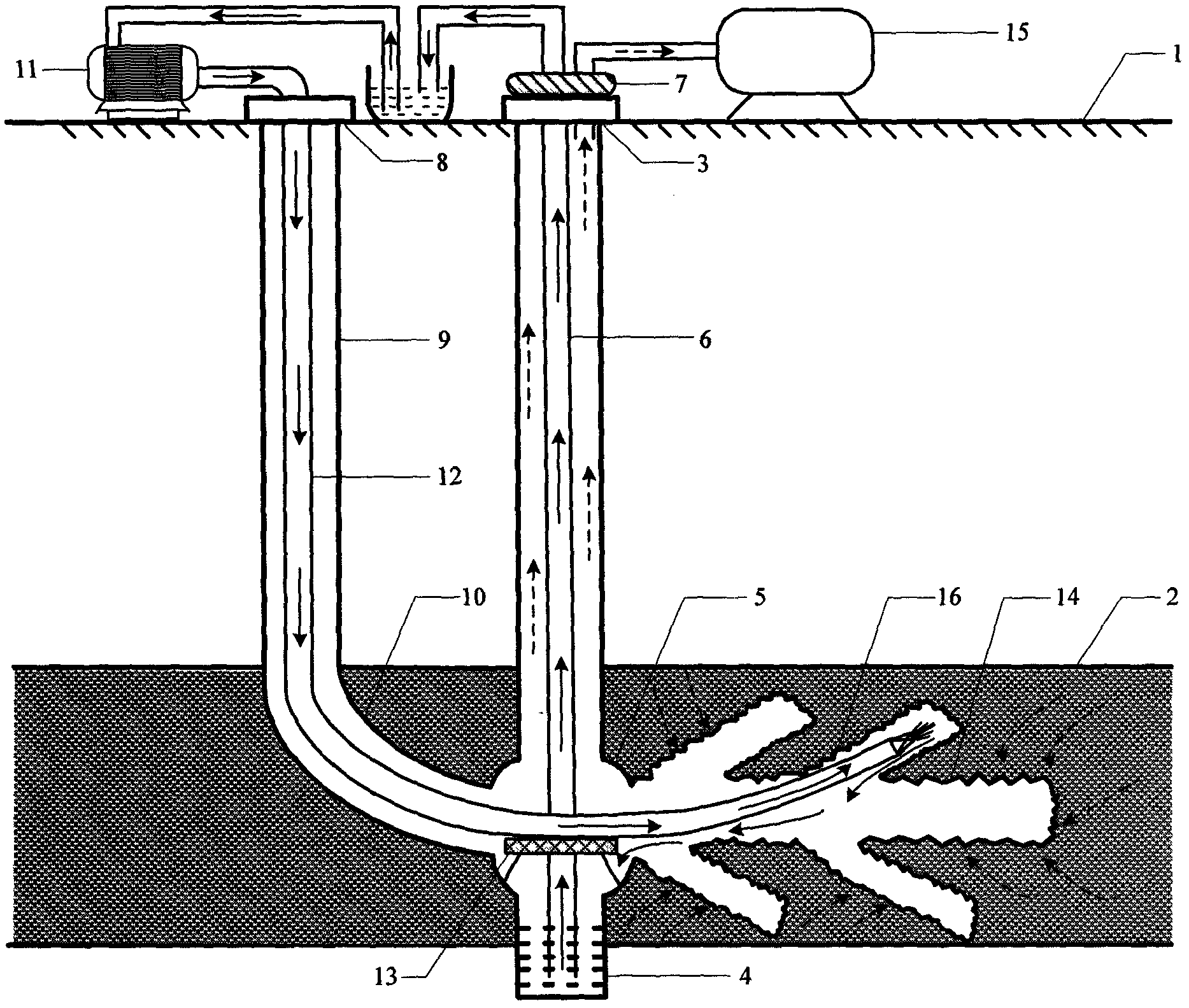

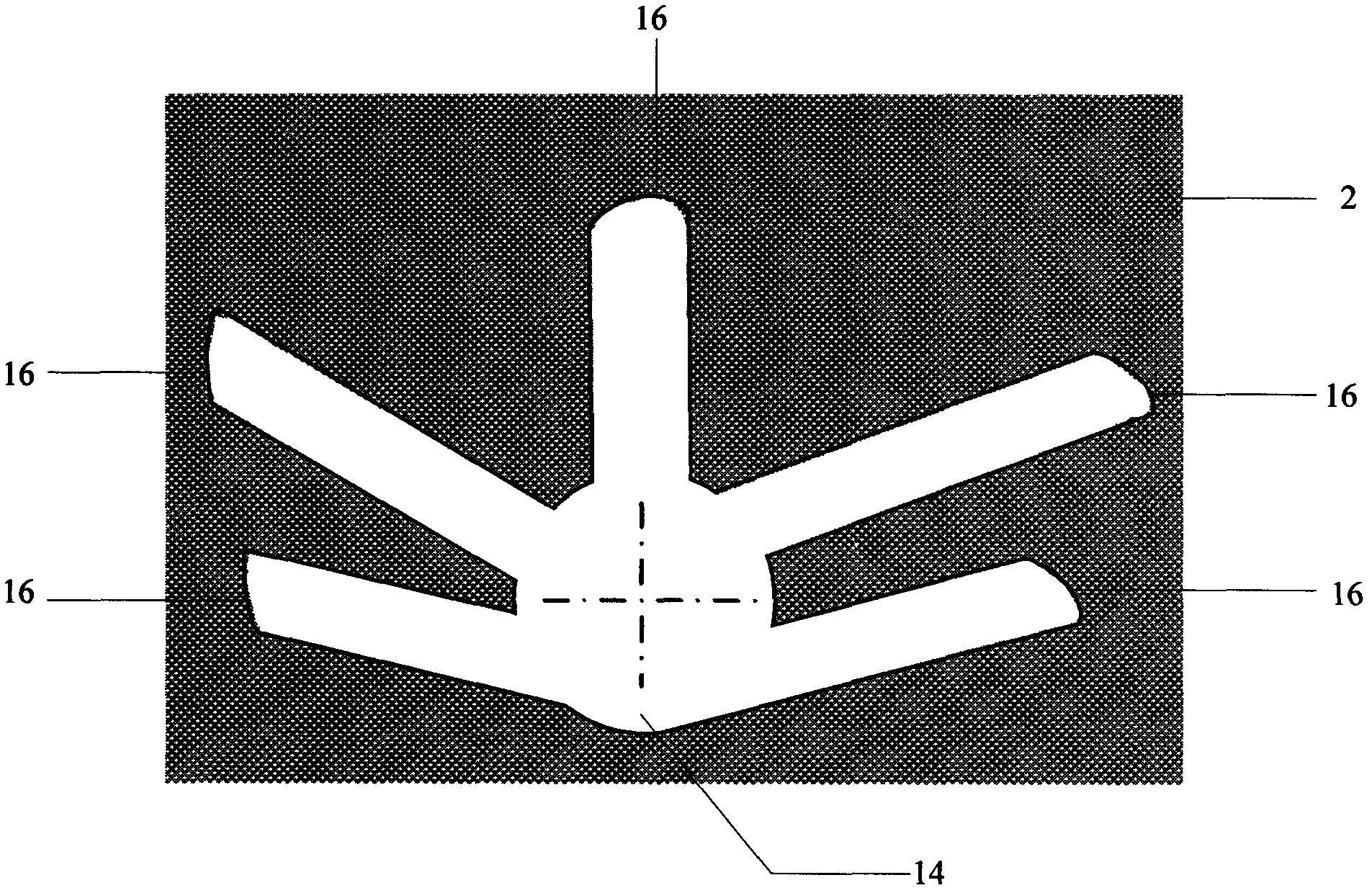

[0024] (1) Firstly, drill a vertical extraction well 3 at a predetermined position, which is drilled from the ground 1, and after passing through the target coal seam 2, continue to drill into a pocket 4 at a certain distance to form a well pit for gathering coal water.

[0025] (2) Then, run a special casing in the second section of the corresponding target coal seam, generally a fiberglass casing, cut off the fiberglass casing to expose the coal seam after cementing, and ream the hole to form the cave 5.

[0026] (3) Coal-water lifting equipment 6 is set in the aforementioned drainage vertical well 3, and a gas, coal and water separation device 7 is installed at the wellhead. The coal-water lifting equipment 6 generally adopts electric submersible pumps, gas-lift diaphragm pumps, rope buckets, screw pumps, jet transport equipment and the like.

[0027] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com