Segmented composite coal-drawing method for surface horizontal wells

A technology of horizontal wells and horizontal sections, which is applied in the field of coal digging and surface horizontal well segmented compound coal dredging, which can solve the problems of difficult large-scale strip pressure relief and outburst elimination targets, difficult construction, small construction aperture, etc., to achieve The effect of shortening the time for outburst elimination and reaching the standard, increasing the amount of coal removal, and increasing the space for pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

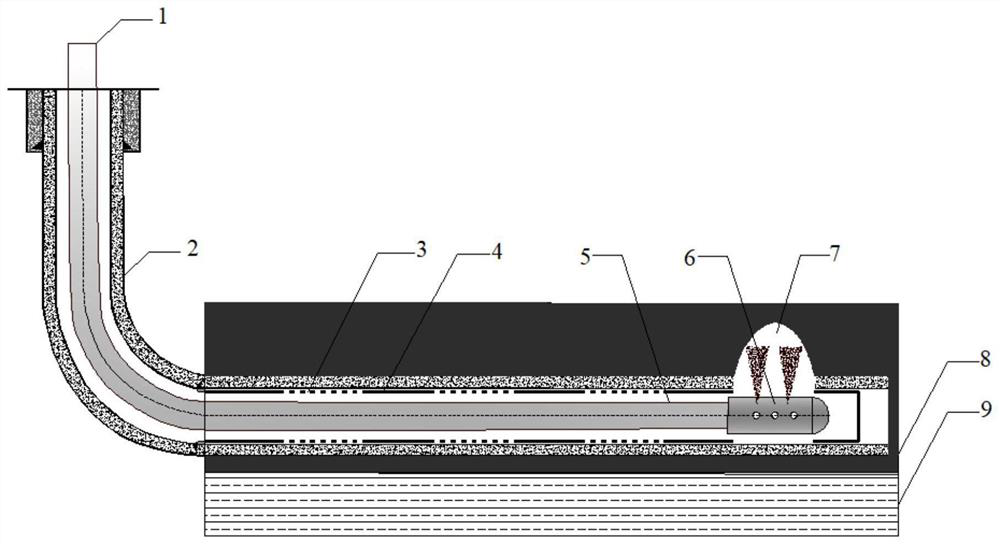

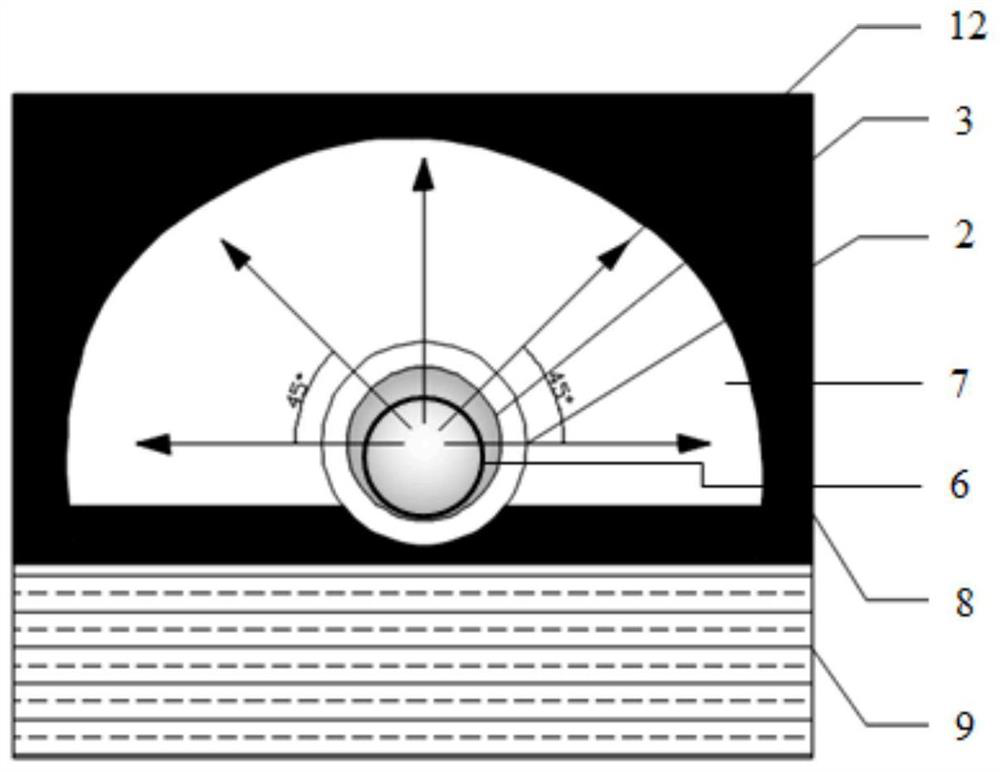

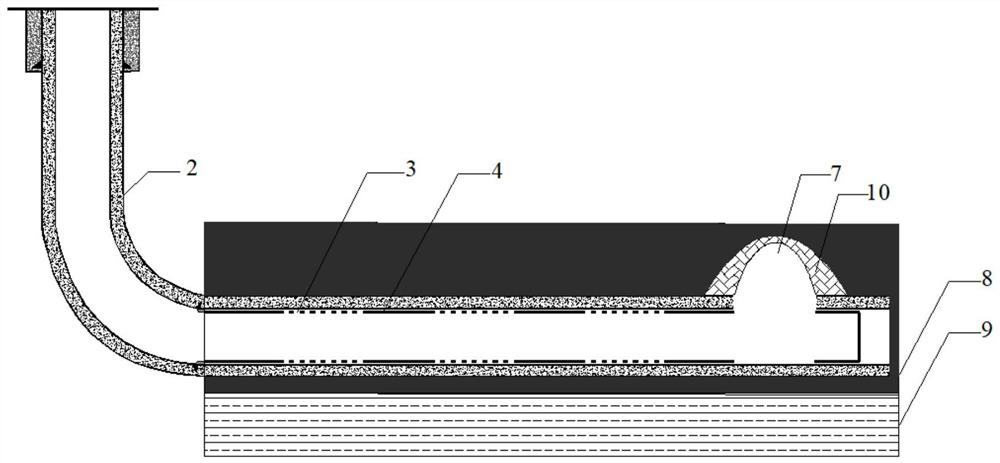

[0040] see Figure 1-Figure 6 , shows a method for stripping pressure relief and outburst elimination of surface horizontal well segmental water / aerodynamic combined coal dredging of the present invention, which is used for striping pressure relief and outburst elimination in broken soft and strong outburst coal seams.

[0041] The method for segmental water / aerodynamic combined coal-drawing strip pressure relief and outburst elimination in a surface horizontal well includes the following steps:

[0042] Step 1: Deploy the L-shaped horizontal well 2 on the ground along the downdip direction of the coal seam 8 roadway, and the horizontal section is located at the bottom of the coal seam 8 (see figure 1 );

[0043] The L-shaped horizontal well 2 is arranged along the down-dipping direction of the coal seam 8 roadway according to the layout direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com