Foal feeding amount control system for coke oven coal feeding cart

A control system and coal truck technology, which are applied in coke ovens, petroleum industry, charging devices, etc., can solve the problems of affecting the production rhythm of coke ovens, long screw feeding time, and less coal addition, etc., and improve labor productivity. , The effect of reducing the number of coke out and accurate quantitative coal feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

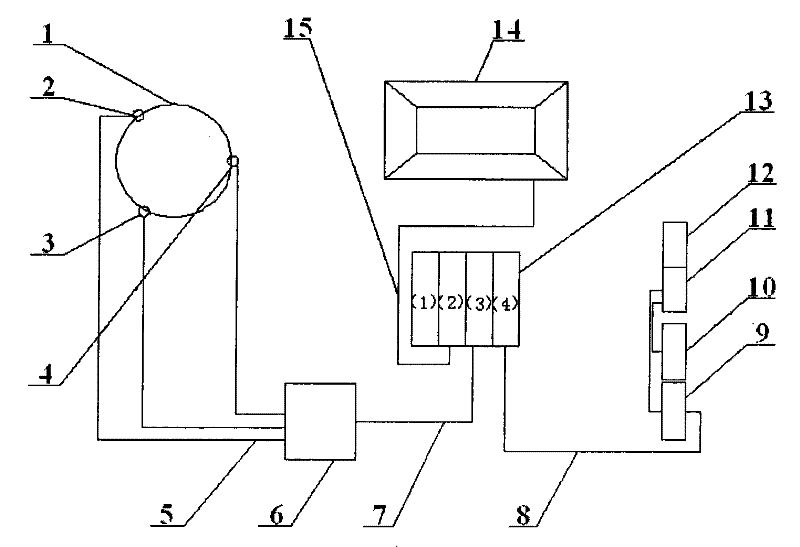

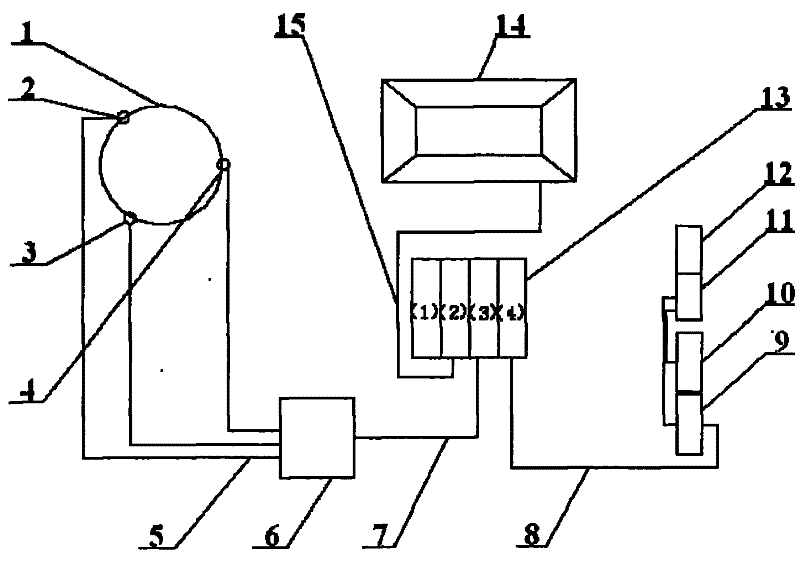

[0025] The coal charging hopper 1 described in the present invention is provided with 3 support points connected with the car body, and the 3 support points are evenly distributed on the outer periphery of the horizontal plane of the coal charging hopper 1, and each support point is installed One said load cell 2, load cell 3, and load cell 4.

[0026] The coal charging hopper 1 is a movable separate body relative to the car body. The coal charging hopper 1 is connected to the car body of the coal charging car through three load cells. The load cells output a standard signal of 4-20mA and send it to the weighing control. 6, setting the tonnage corresponding to the 4mA and 20mA standard signals on the weighing controller 6, and the standard signal is linearly proportional to the corresponding tonnage.

Embodiment 2

[0028] The coal addition control system described in the present invention is provided with a PLC13, and the PLC13 includes a power supply module, a CPU module, an analog input module and a switch output module. The PLC is a programmable controller, which is a new type of electrical control device. PLC has the following advantages: high reliability, strong anti-interference ability; simple system structure, convenient combination, strong versatility; simple programming, convenient use and maintenance; strong function, wide application range; small size, light weight, low power consumption. The invention utilizes the PLC to detect the electric current of the motor and controls the operation of the motor by comparing the magnitude of the load current. Among them, the power module provides the working energy of the PLC; the CPU module is the central processing unit, which is the core component of the PLC; the analog input module accepts the analog signal of the weight of coal, an...

Embodiment 3

[0030] Establish weighing controller 6 in the coal addition control system of the present invention, press figure 1 In the example, the load cells are respectively load cell 2, load cell 3 and load cell 4, each of the above load cells is connected to the weighing controller 6 through the sensor signal line 5, and the load cell The load cell 2, the load cell 3, and the load cell 4 convert the weight of the coal hopper 1 into a standard signal and send it to the weighing controller 6; the weighing controller 6 is connected to the PLC13 through the standard signal line 7. The quasi-signal line 7 is a standard signal line of 4 mA and 20 mA.

[0031] The load cell outputs the standard signal of 4-20mA, which is sent to the weighing controller 6, and the corresponding tonnage of the 4mA and 20mA standard signals is set on the weighing controller, and the standard signal is linearly proportional to the corresponding tonnage. The standard signal output by weighing controller 6 is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com