Forge welding double-middle-plate structure chute

A plate structure and double-layer structure technology, applied in the field of the middle tank, can solve the problems of low strength of the middle tank, limited coal flow, unstable quality, etc., and achieve the effect of increased strength, high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

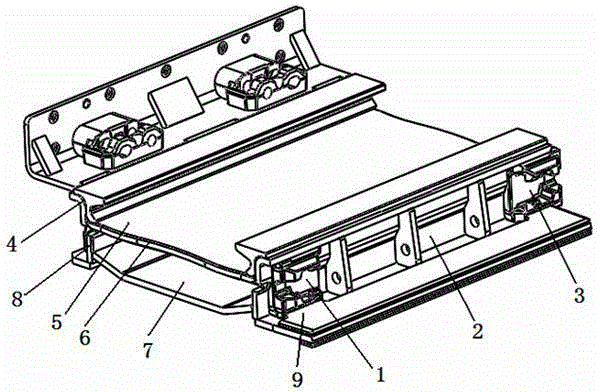

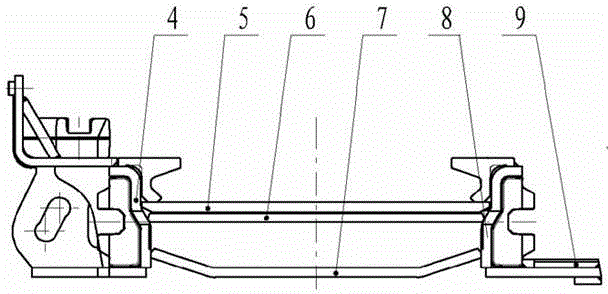

[0017] like figure 1 and figure 2 Shown, the present invention comprises middle plate, bottom plate 7, the baffle stand plate 4 that is positioned at middle plate both sides, the shovel stand plate 8 that is positioned at the both sides of bottom plate 7 and middle plate and bottom plate 7, is positioned at the shovel stand plate 8 outsides Shovel coal plate 9, above-mentioned shovel vertical board 8 is flat plate. During manufacture, the present invention adopts a forged and welded structure, and all components do not adopt cast products; the structure is simple, easy to manufacture, the contact specific pressure is small, and it is wear-resistant.

[0018] The middle plate is a double-layer structure, including the live middle plate 5 and the lower middle plate 6. The joints of the middle plates adopt a W-shaped structure, which can sacrifice part of the wear of the middle plates to protect most of the joints from wear. The strength of the invention is guaranteed by the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com