Patents

Literature

97 results about "Forge welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forge welding (FOW) is a solid-state welding process that joins two pieces of metal by heating them to a high temperature and then hammering them together. It may also consist of heating and forcing the metals together with presses or other means, creating enough pressure to cause plastic deformation at the weld surfaces. The process is one of the simplest methods of joining metals and has been used since ancient times. Forge welding is versatile, being able to join a host of similar and dissimilar metals. With the invention of electrical and gas welding methods during the Industrial Revolution, manual forge-welding has been largely replaced, although automated forge-welding is a common manufacturing process.

Marking of pipe joints

An improved method of permanently marking the location of a tubular joint, the method including creating a cavity into the end surface of one of the tubular ends that are to be joined by a forge weld or screw thread connection, inserting a marker into said cavity and subsequently joining the tubular ends.

Owner:PAPER CONVERTING MASCH CO INC +1

Joining expandable tubulars

A method of joining expandable tubulars includes joining the tubulars by forge welding and flushing a reducing flushing gas around the heated tubular ends during at least part of the forge welding operation such that oxides are removed from the forge welded tubular ends and the amount of irregularities between the forge welded tubular ends is limited.

Owner:SHELL OIL CO

Marking of pipe joints

An improved method of permanently marking the location of a tubular joint, the method including creating a cavity into the end surface of one of the tubular ends that are to be joined by a forge weld or screw thread connection, inserting a marker into said cavity and subsequently joining the tubular ends.

Owner:PAPER CONVERTING MASCH CO INC +1

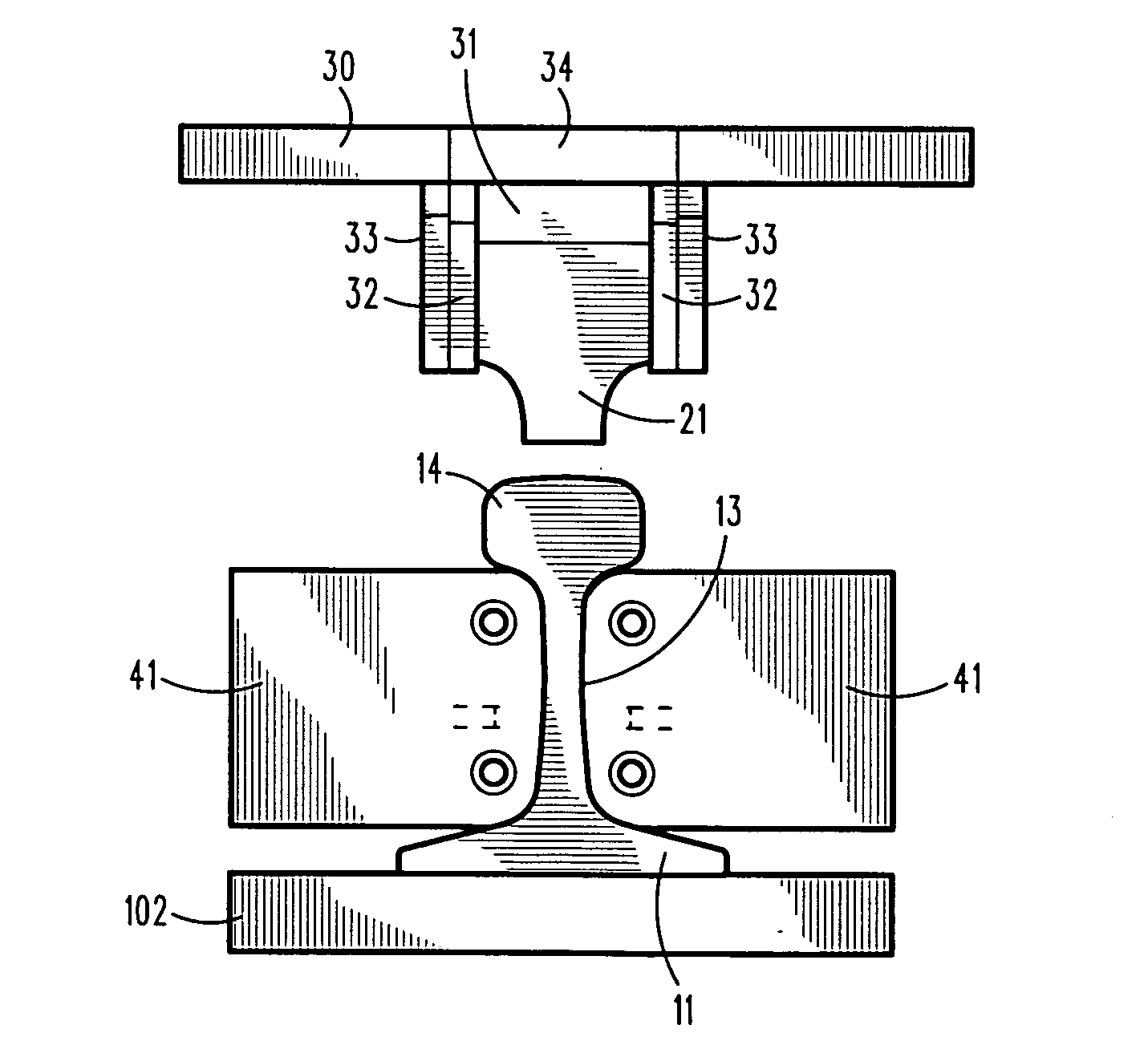

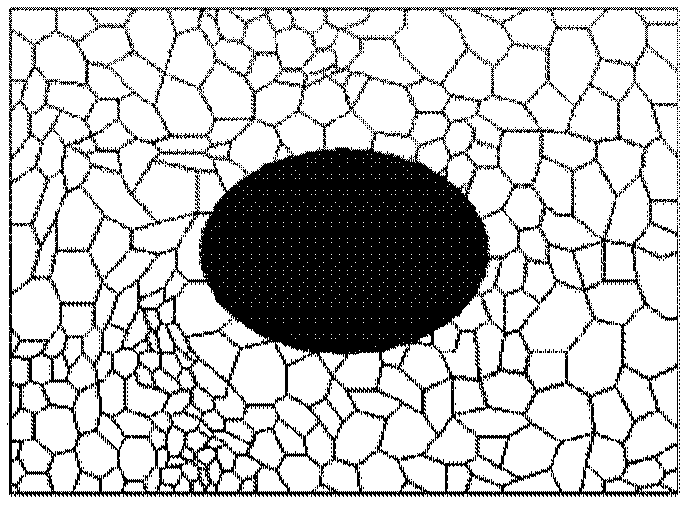

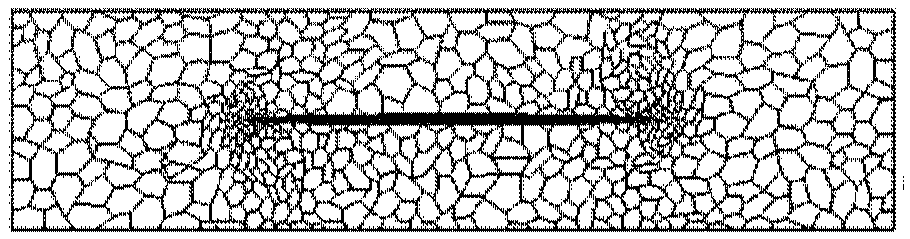

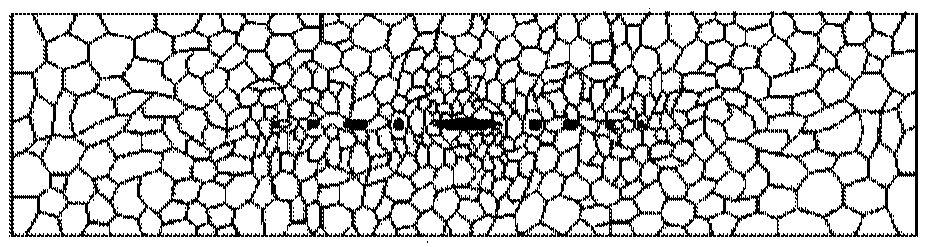

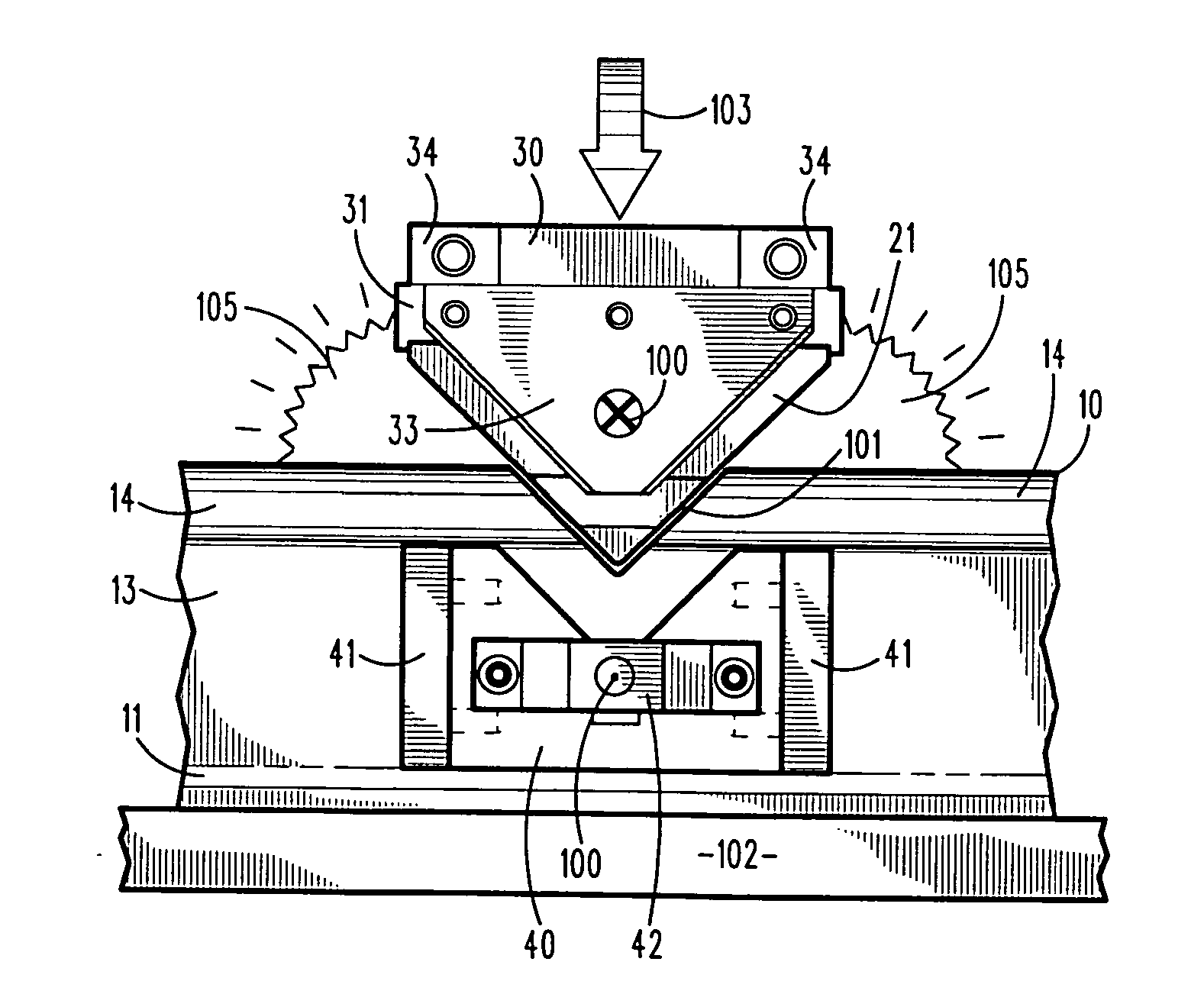

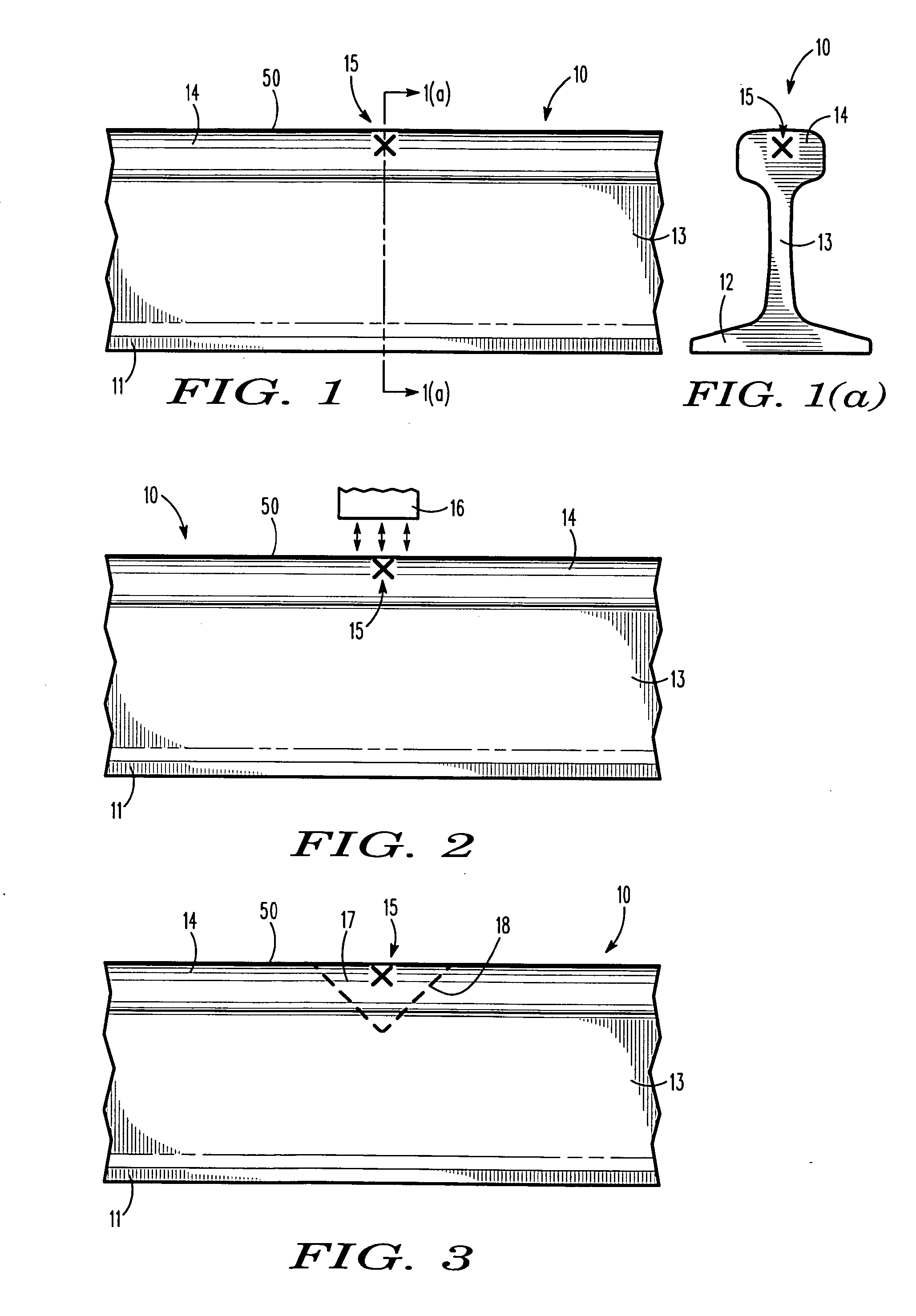

Method and repair insert for repairing metallic structure

InactiveUS20110233293A1Effective timeMore time of runningRailsRailway track constructionElectrical resistance and conductancePower flow

A rail repair method and insert therefor enables repair of rails and rail-like structures. A rail defect is initially identified and removed as contained within a volumetric material portion so as to form a contoured void while maintaining continuity of the rail opposite the void. A pre-formed insert is then placed into the void thereby effecting a rail-to-insert interface. Current is driven through the interface as force directs the insert against the rail. Resistance heat and pressure weld the insert to the rail. The flash welding aspects remove oxides and other impurities from the interface, and the forge welding aspects create a robust solid state weld. Excess material, whether flash, rail, or insert-based, is removed during the finishing processes to provide a virtually seamless rail repair. The solid state weld repair insert and underlying methodology enabled thereby may be used to repair any number of targeted metallic rail-like structures.

Owner:HOLLAND CO

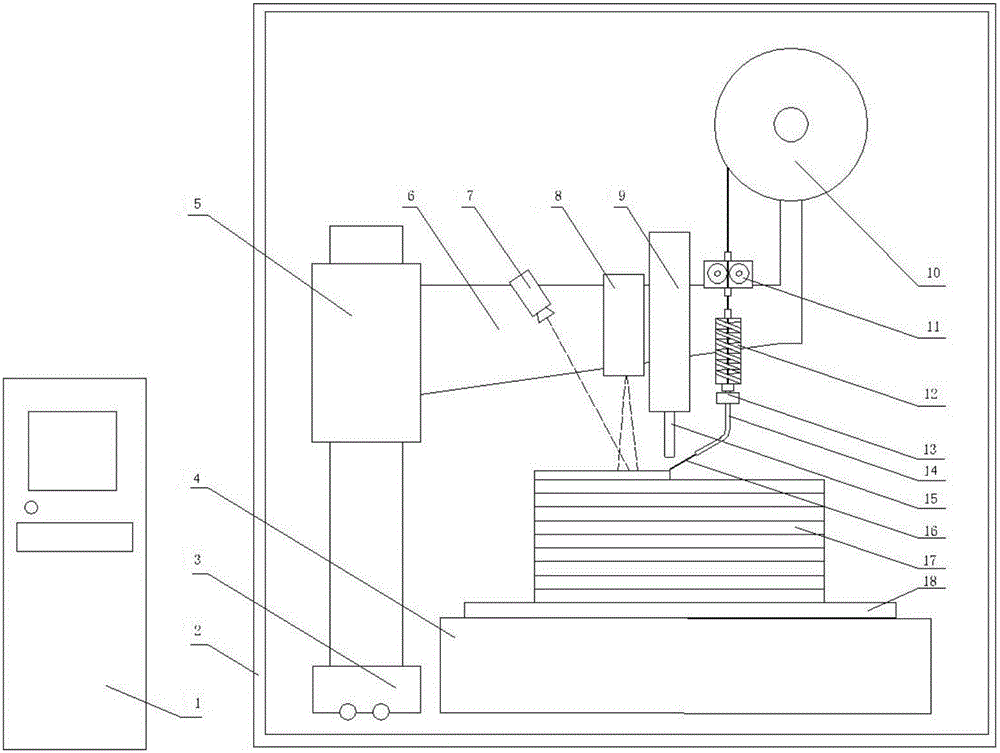

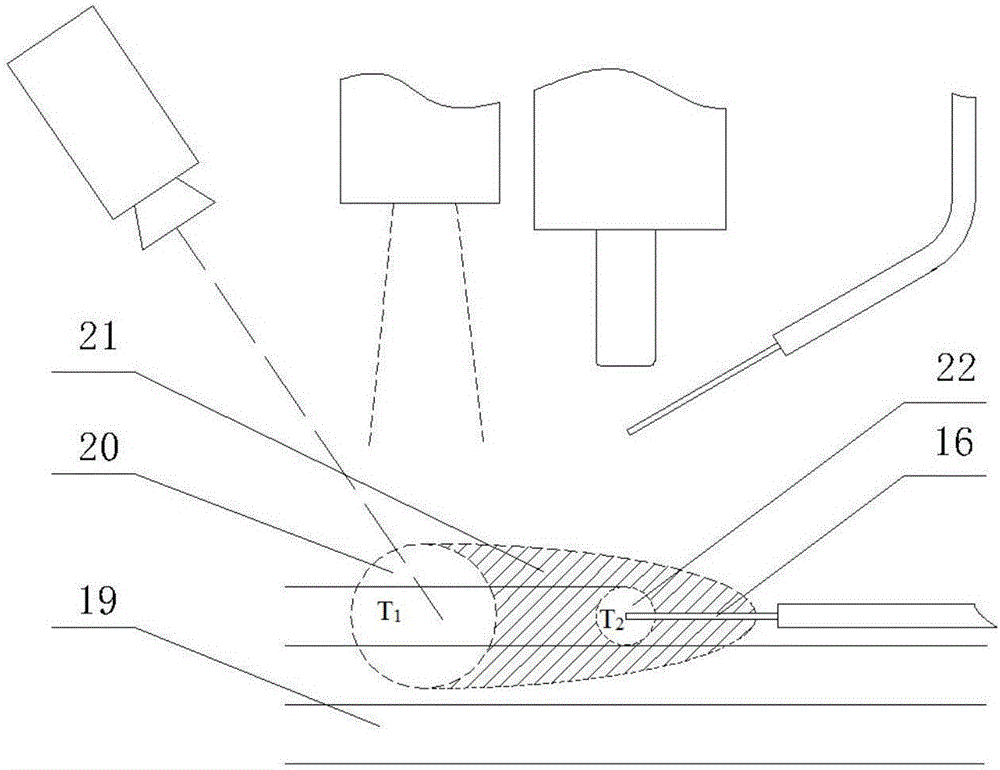

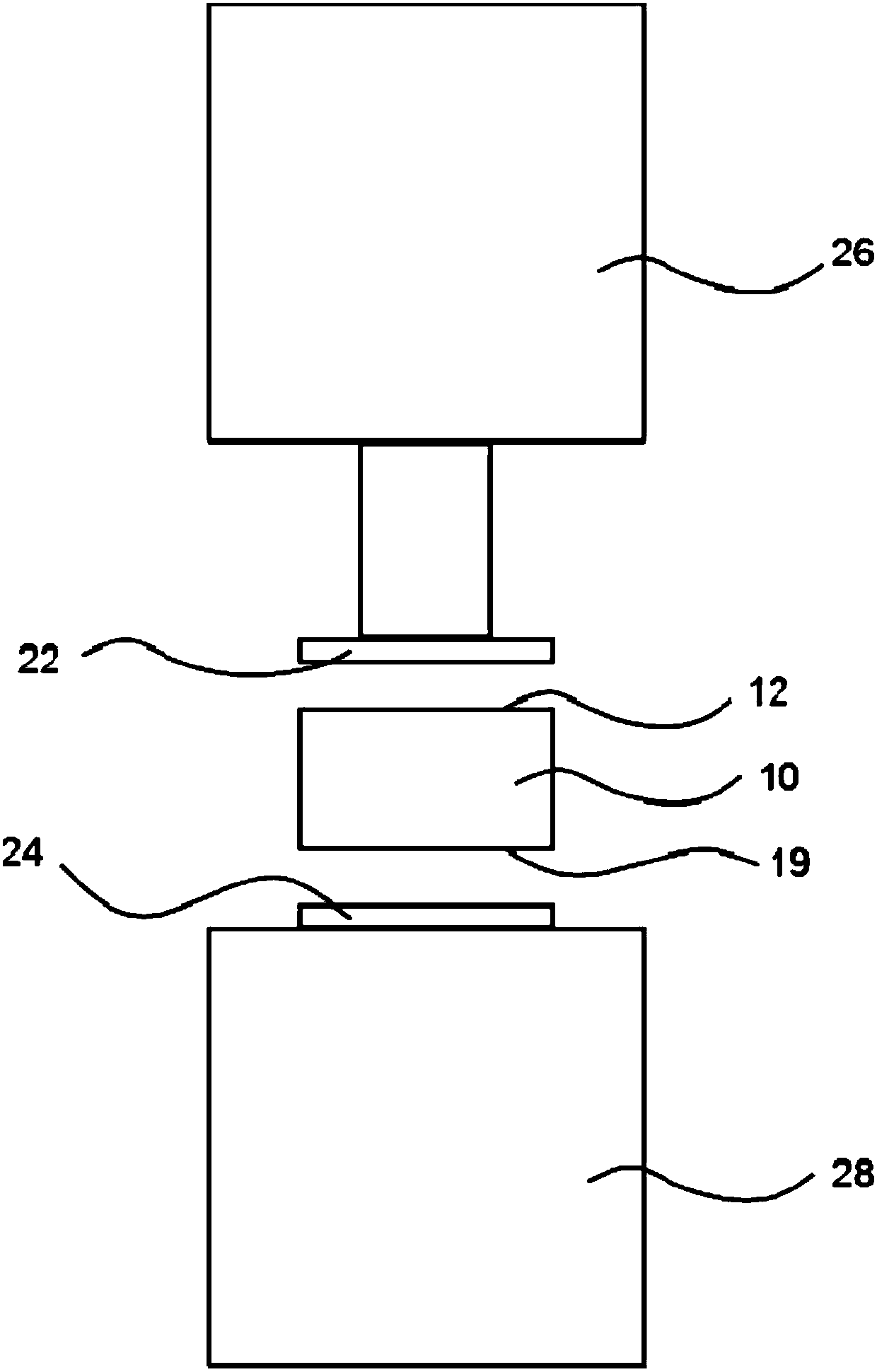

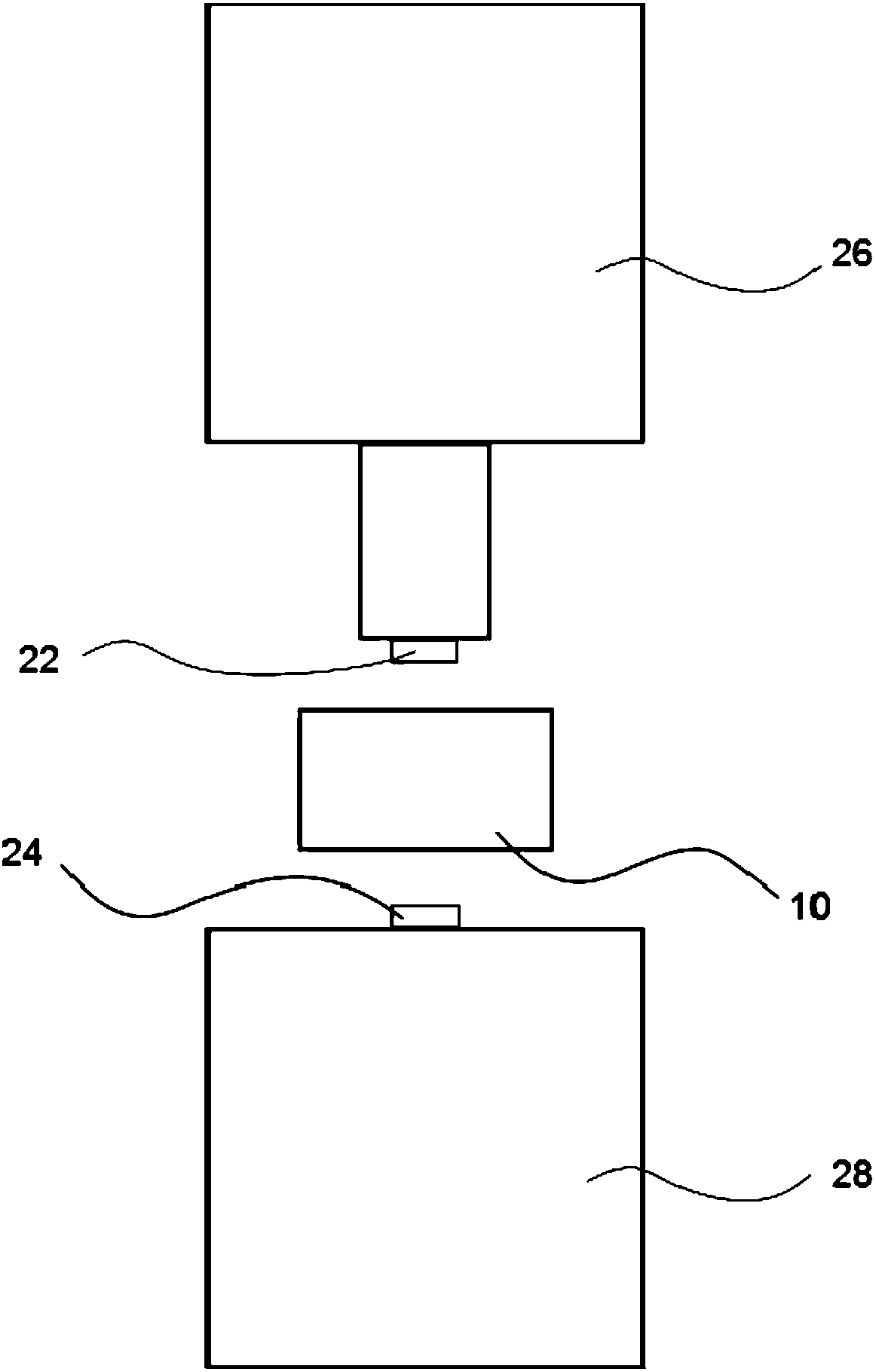

Metal forge welding additional material manufacturing device and forging method

ActiveCN106825348AImprove reliabilityImprove consistencyAdditive manufacturing apparatusPower hammersReciprocating motionManufactured material

The invention provides a metal forge welding additional material manufacturing device and a forging method. The metal forge welding additional material manufacturing device comprises a work bin and a control unit connected with the work bin. The work bin is internally provided with a forging base plate, a machining unit and a moving unit. The moving unit is arranged at the side portion of the forging base plate. The machining unit is located on one side of the moving unit. The machining unit is located above the forging base plate when machining a workpiece. The machining unit comprises a preheating unit, a forging unit, a wire feeder and a wire storage device, all of which are sequentially arranged in the direction from the moving unit to the forging base plate. The forging unit comprises a forging hammer capable of reciprocating up and down, a forging area is formed between the lower portion of the forging hammer and the surface of the workpiece, the forging hammer reciprocates in the forging area, and accordingly the workpiece and a metal wire can be continuously forged. An inner microscopic structure in the manufactured material is a forging structure, grain is fine, the mechanical performance s good, air holes and other common welding metallurgical defects cannot occur, and the reliability and consistency of the metal additional material manufacturing component performance can be greatly improved.

Owner:青岛卓思三维智造技术有限公司

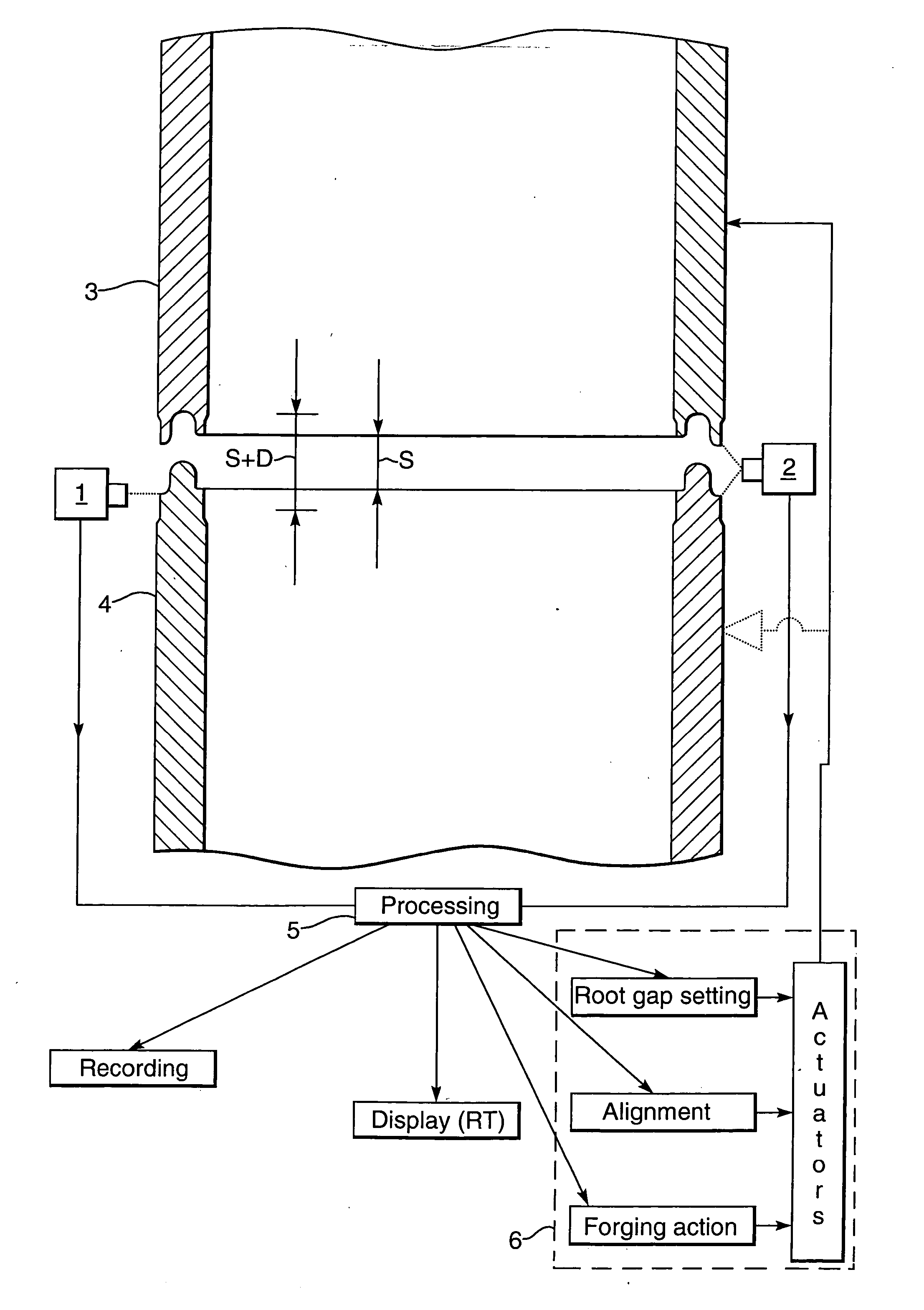

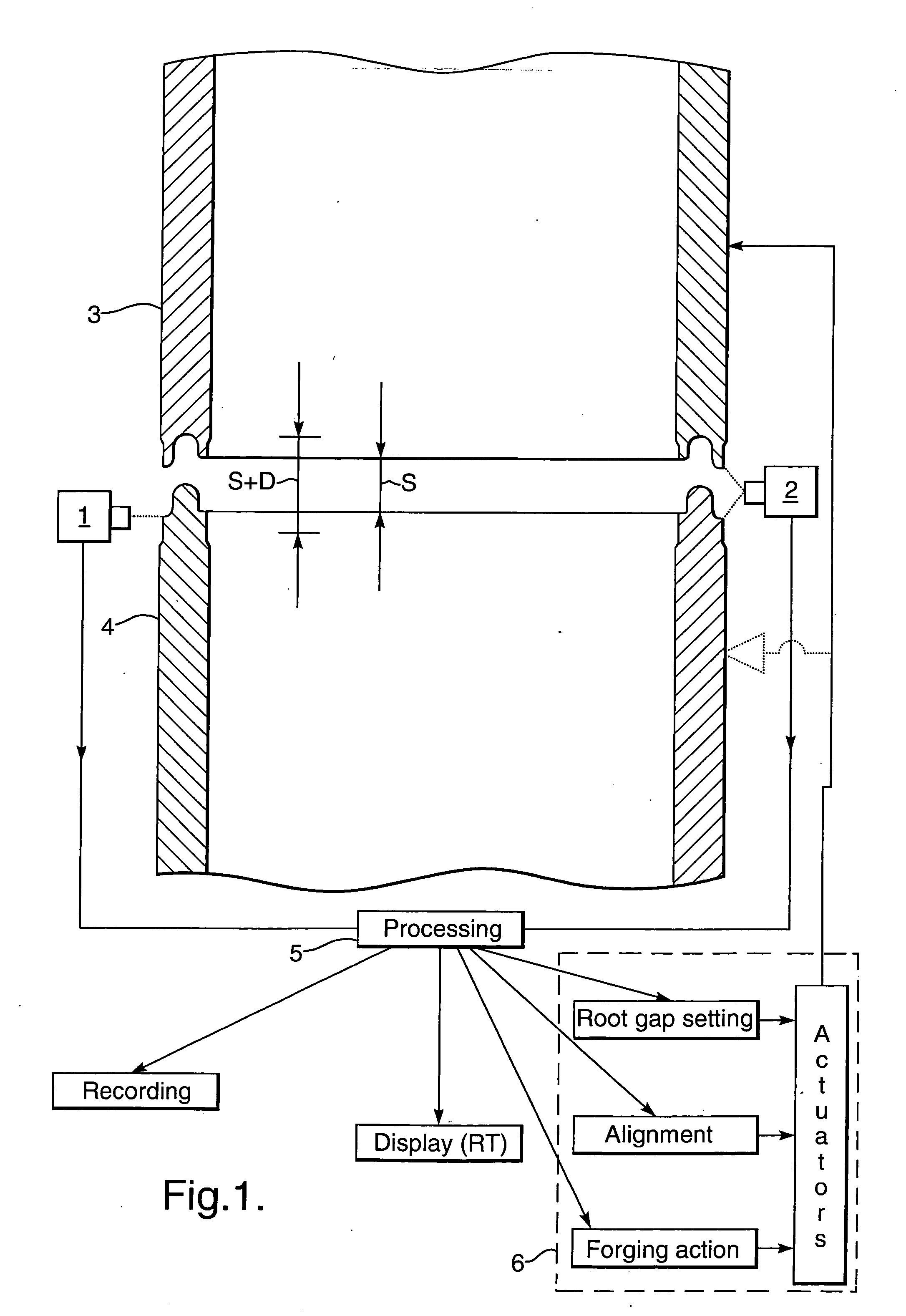

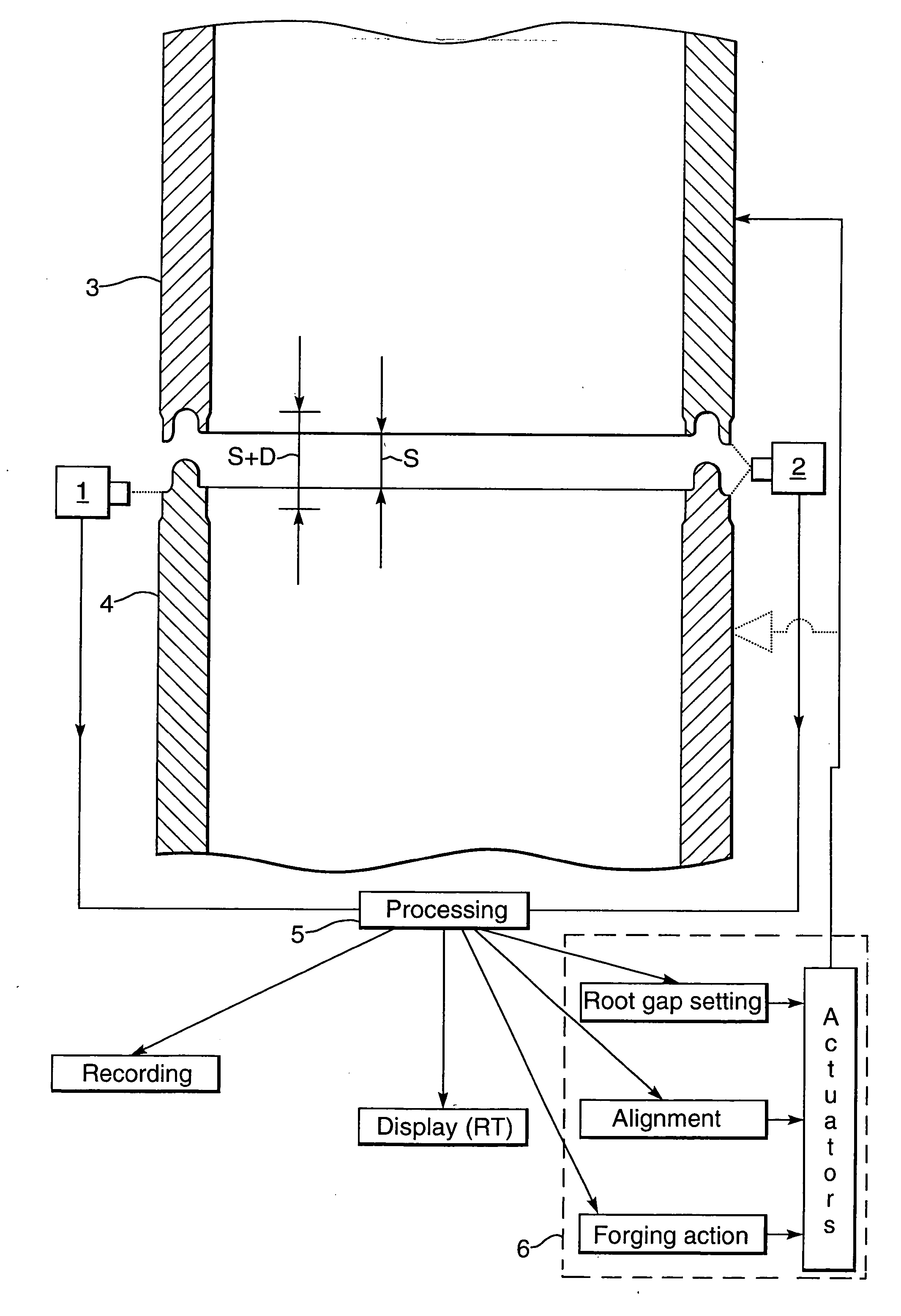

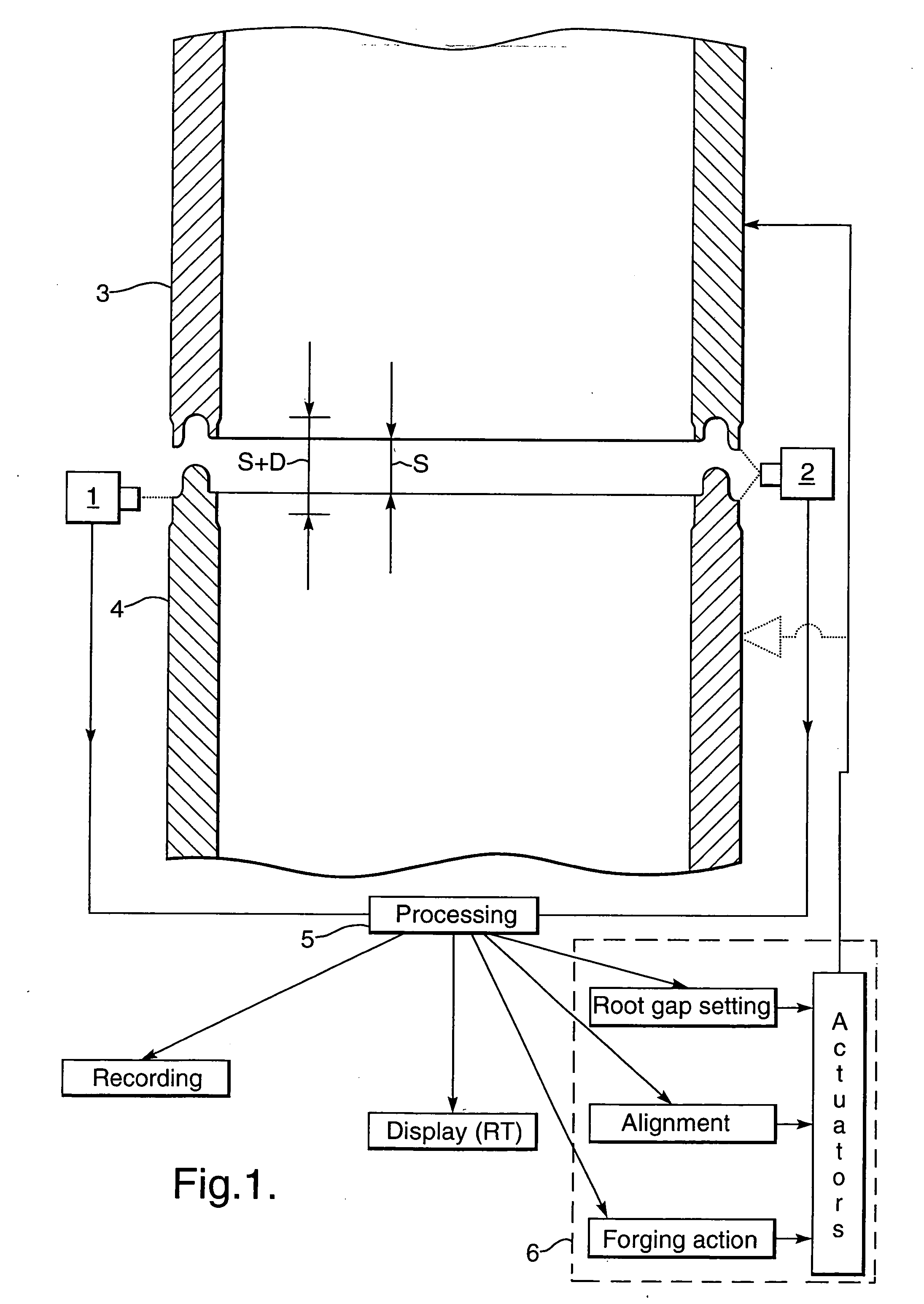

Forge welding process

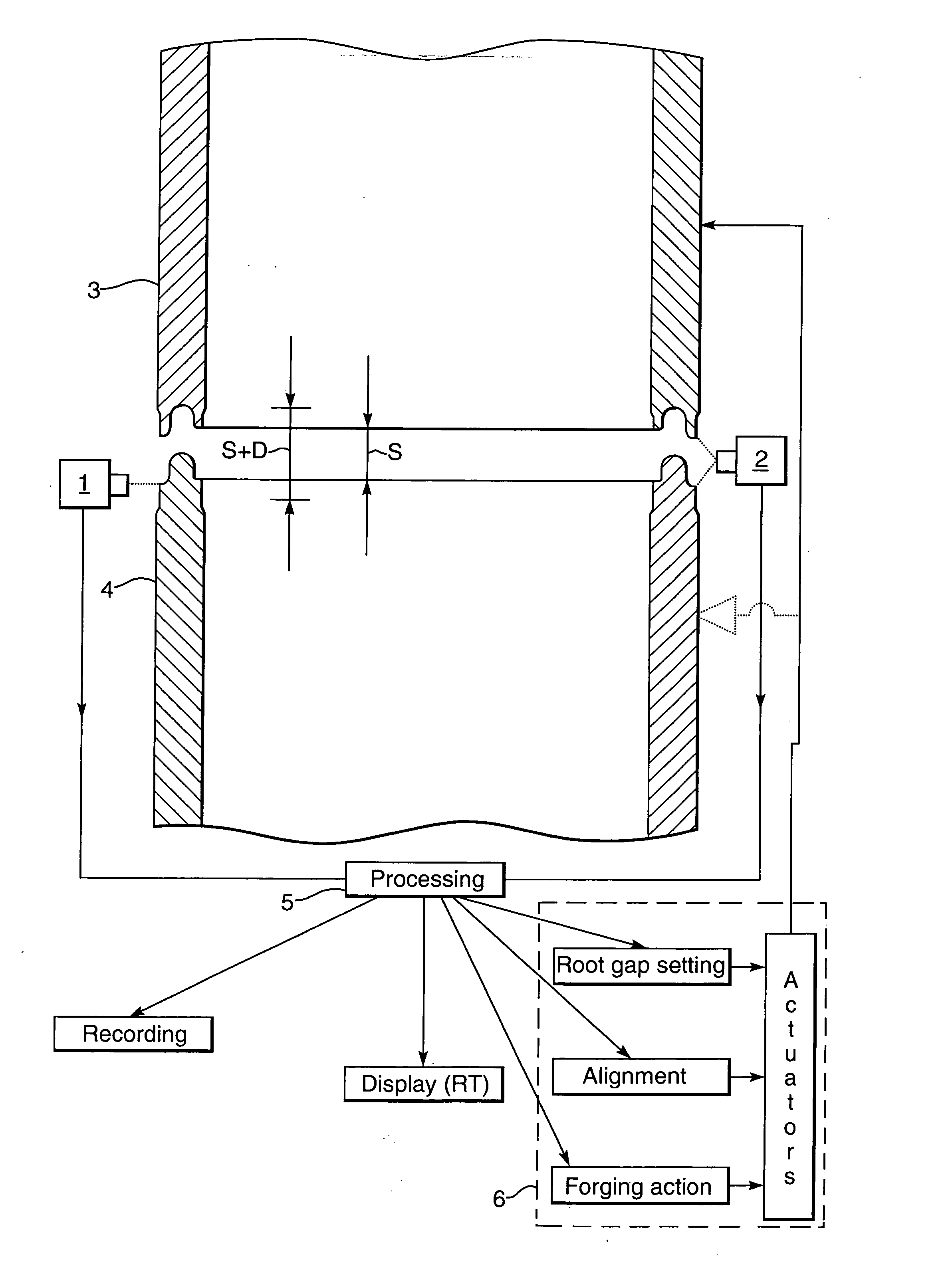

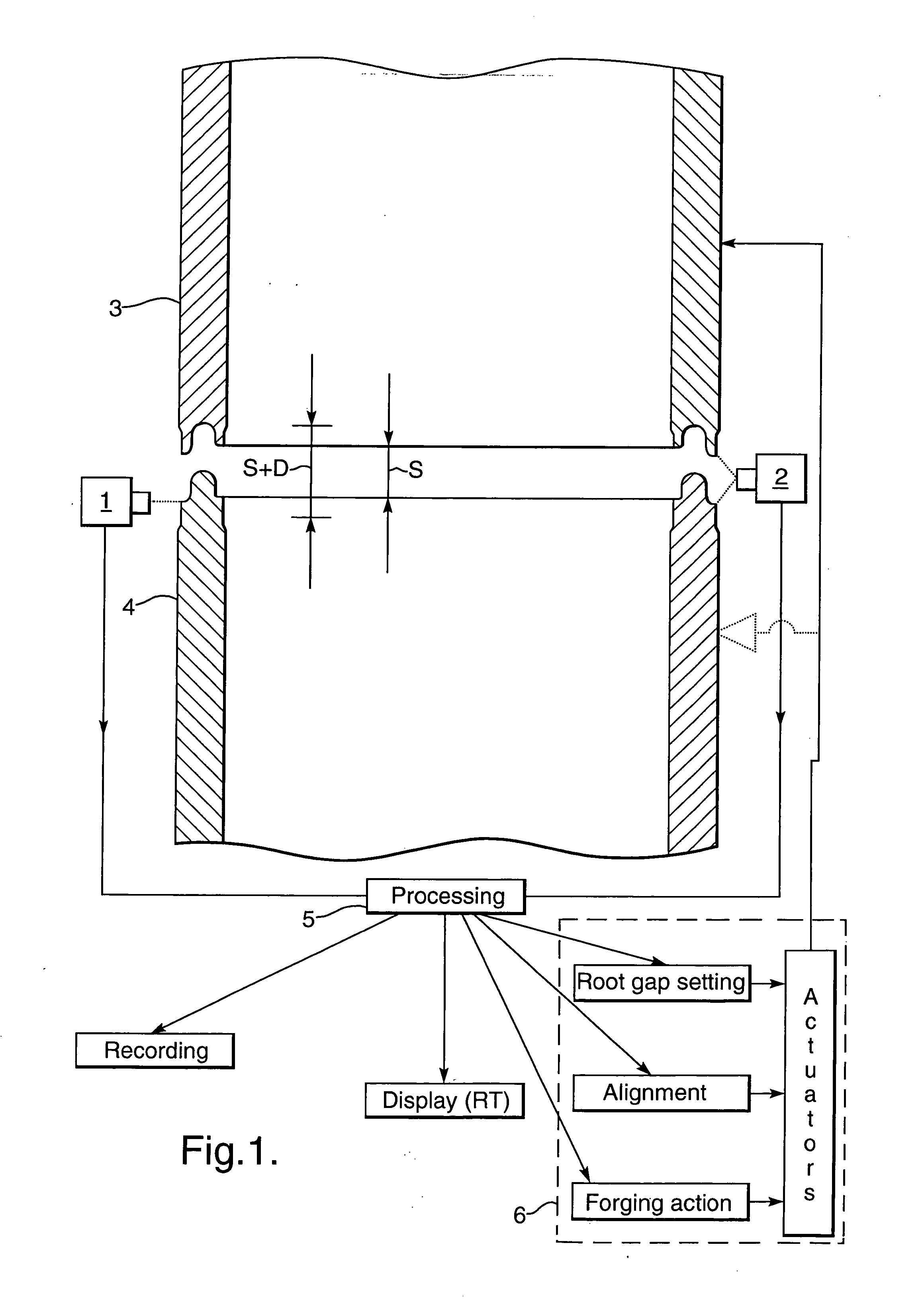

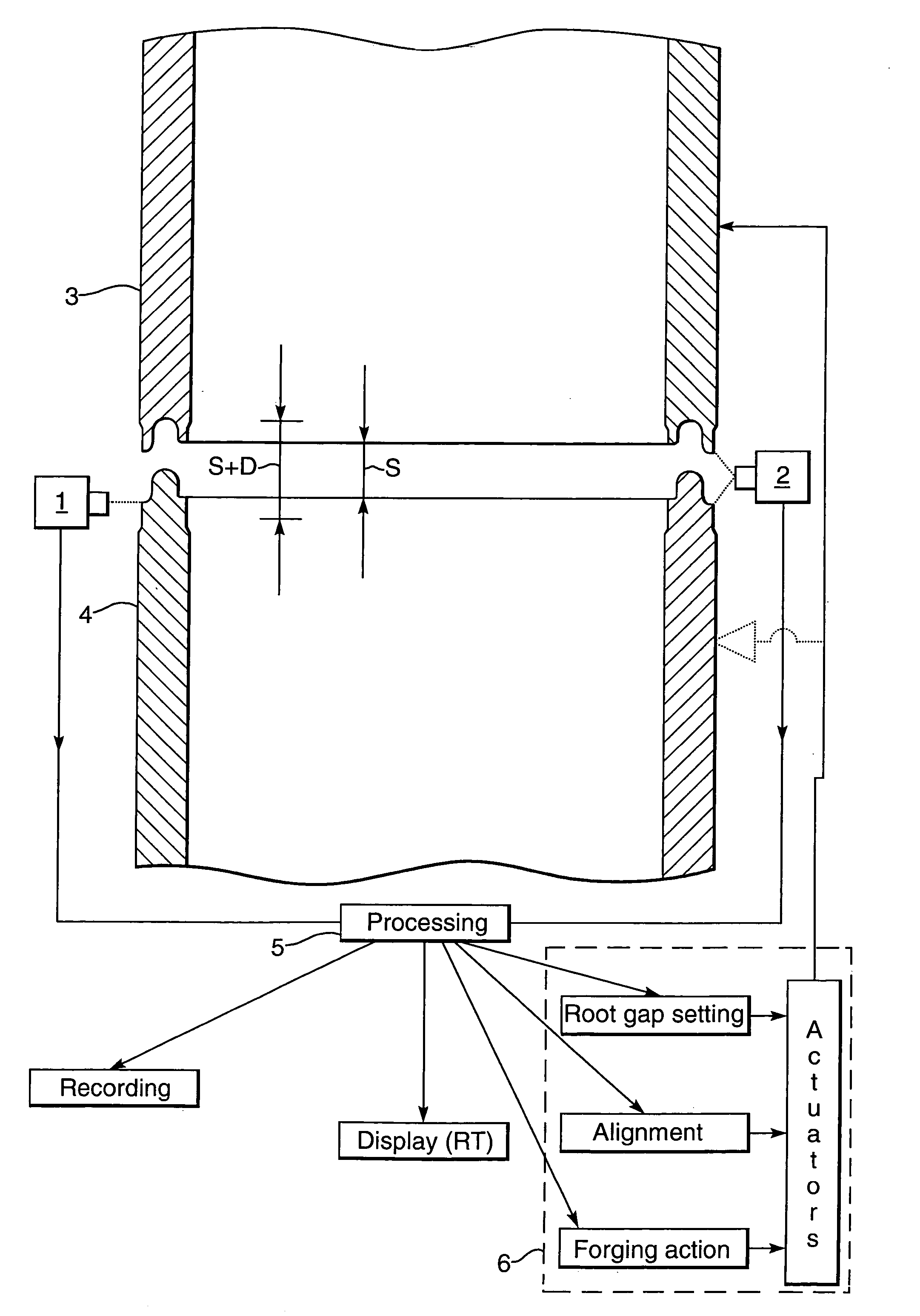

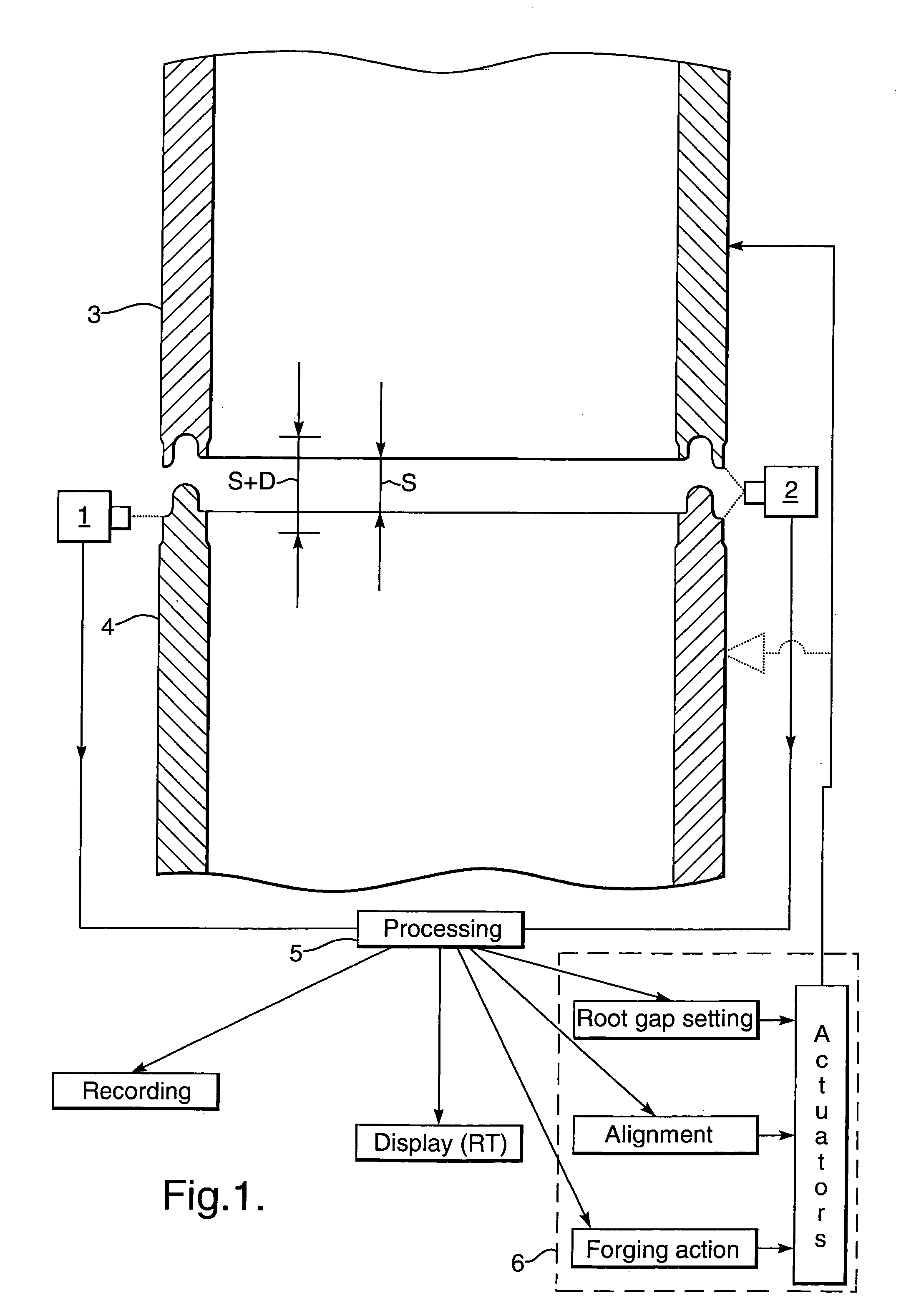

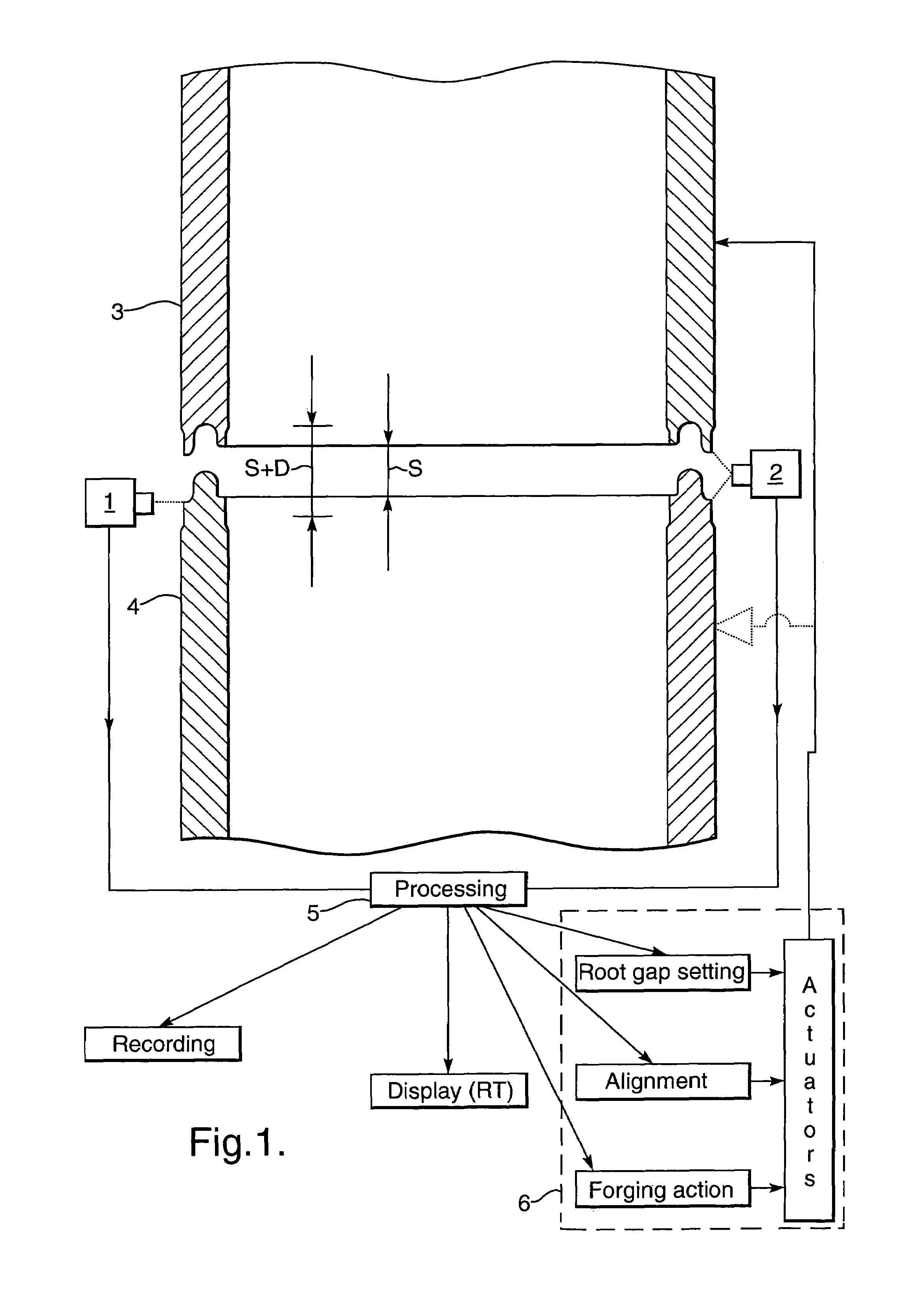

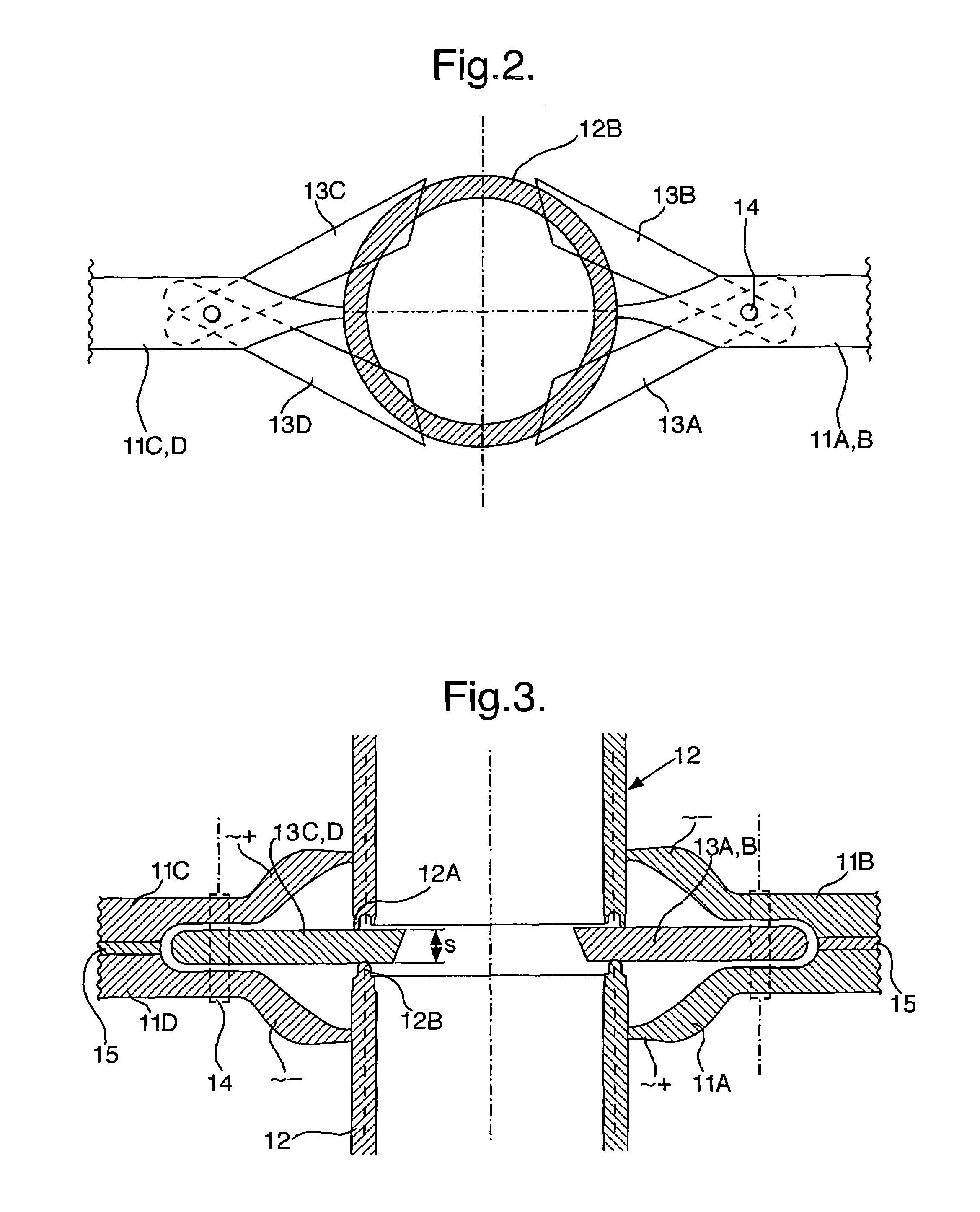

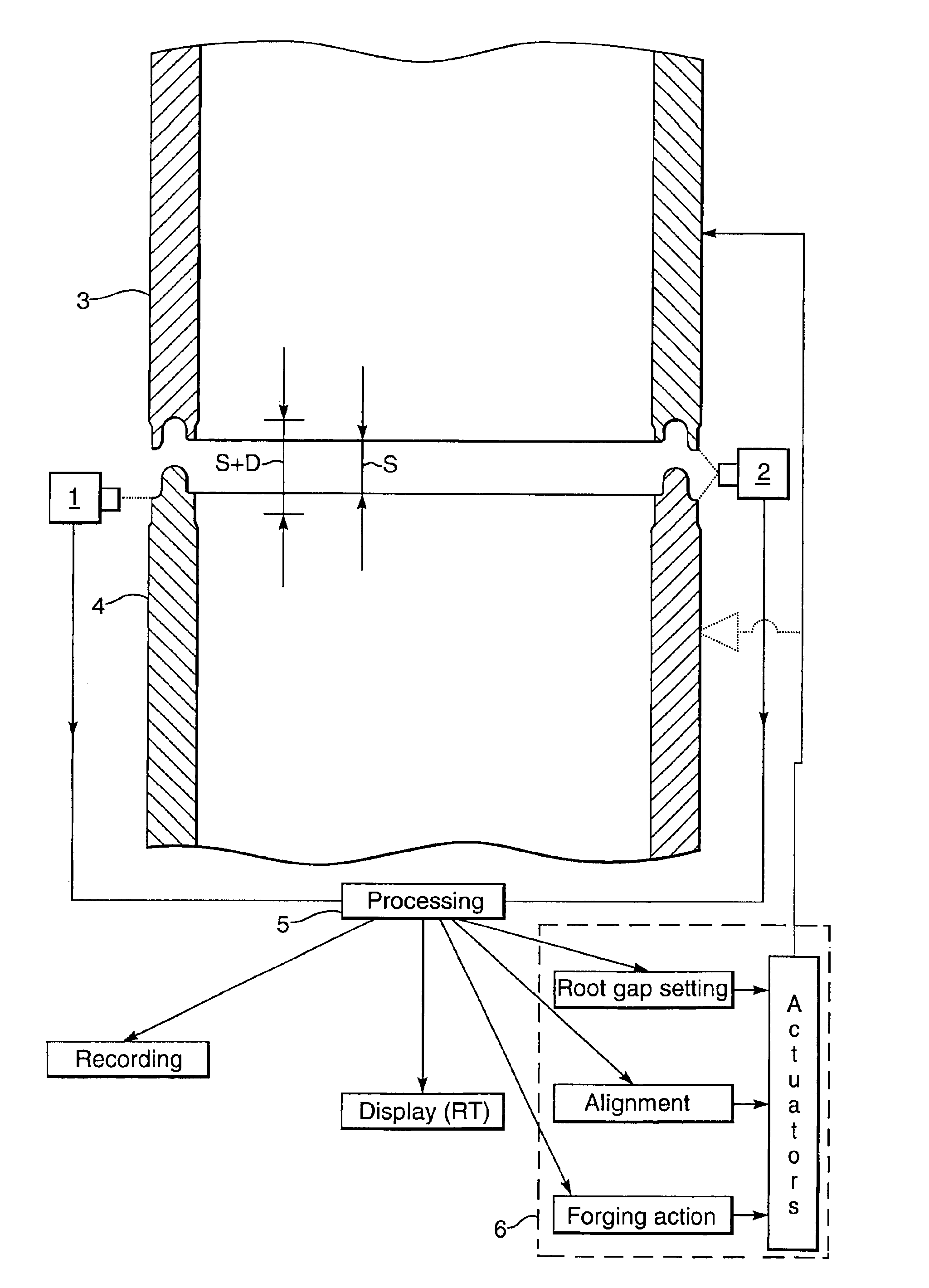

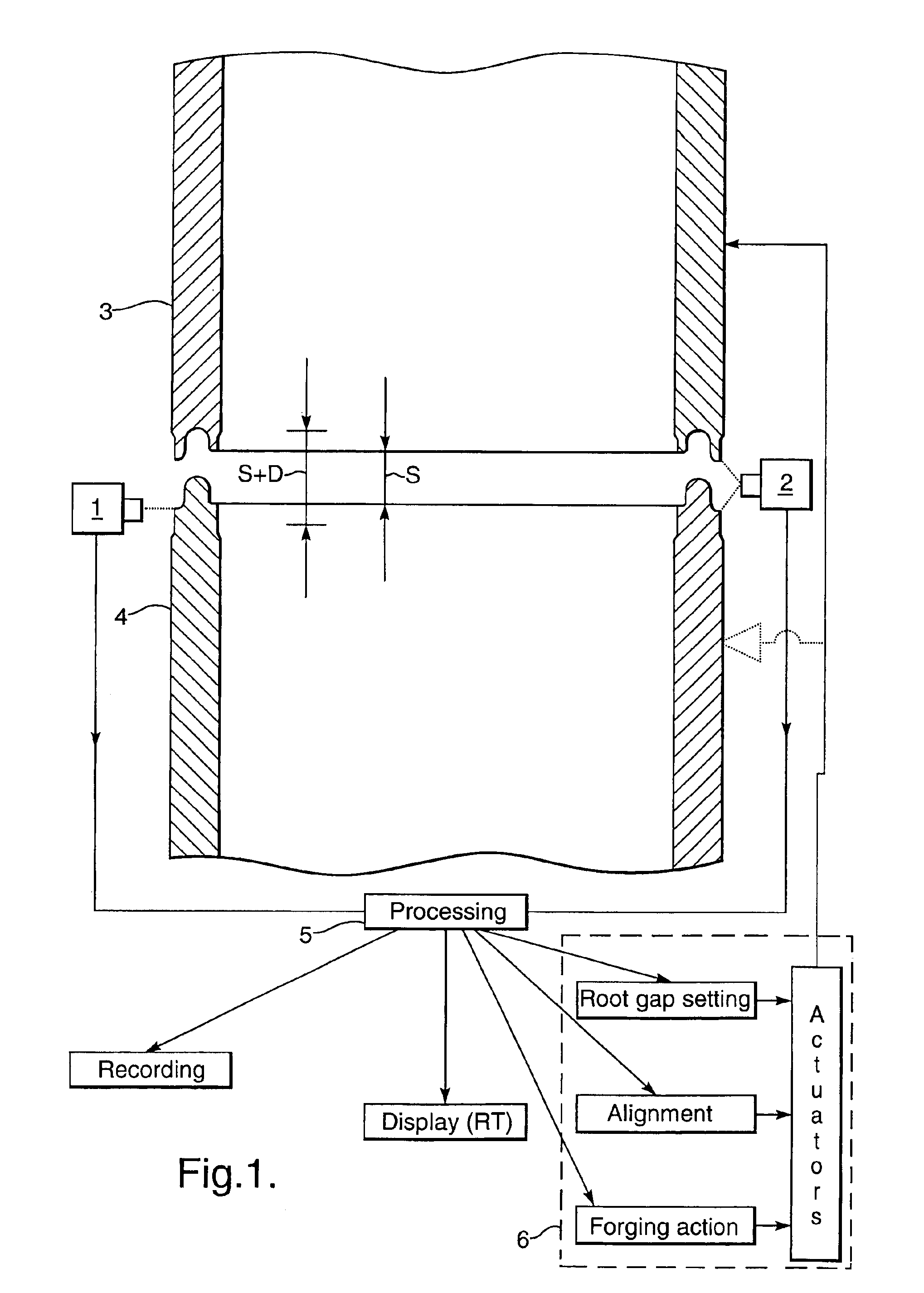

InactiveUS7282663B2Keep the distanceSoldering apparatusWelding monitoring devicesMonitoring systemShielding gas

An automated method for forge welding tubulars including heating the tubular ends to be joined in a welding chamber while the heated tubular ends are maintained aligned and parallel relative to each other and at a small spacing, whereupon the heated tubular ends are pressed together while a reducing shield gas is injected into the chamber. The positions of the tubular ends are monitored by cameras which are coupled to a pyrometric and position monitoring system which automatically adjusts the position of the tubular ends relative to each other and the heat supplied to the tubular ends during the heating step until the tubular ends have reached a predetermined temperature, whereupon the tubular ends are moved towards each other along a distance which exceeds the spacing monitored between the tubular ends during the heating step with a selected extra distance, such that the tubular ends are firmly pressed against each other and the amount of external and / or internal upset of the tubular ends in the welding zone is limited to an acceptable level.

Owner:SHELL OIL CO

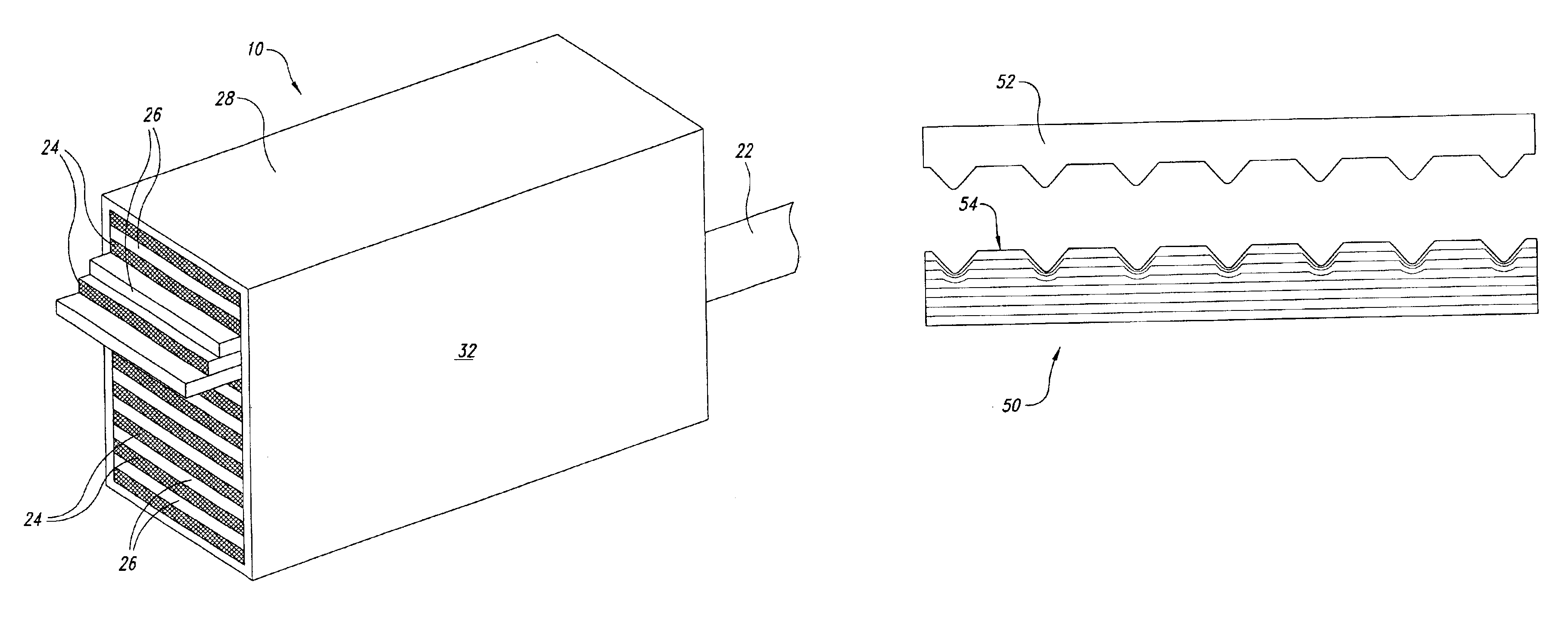

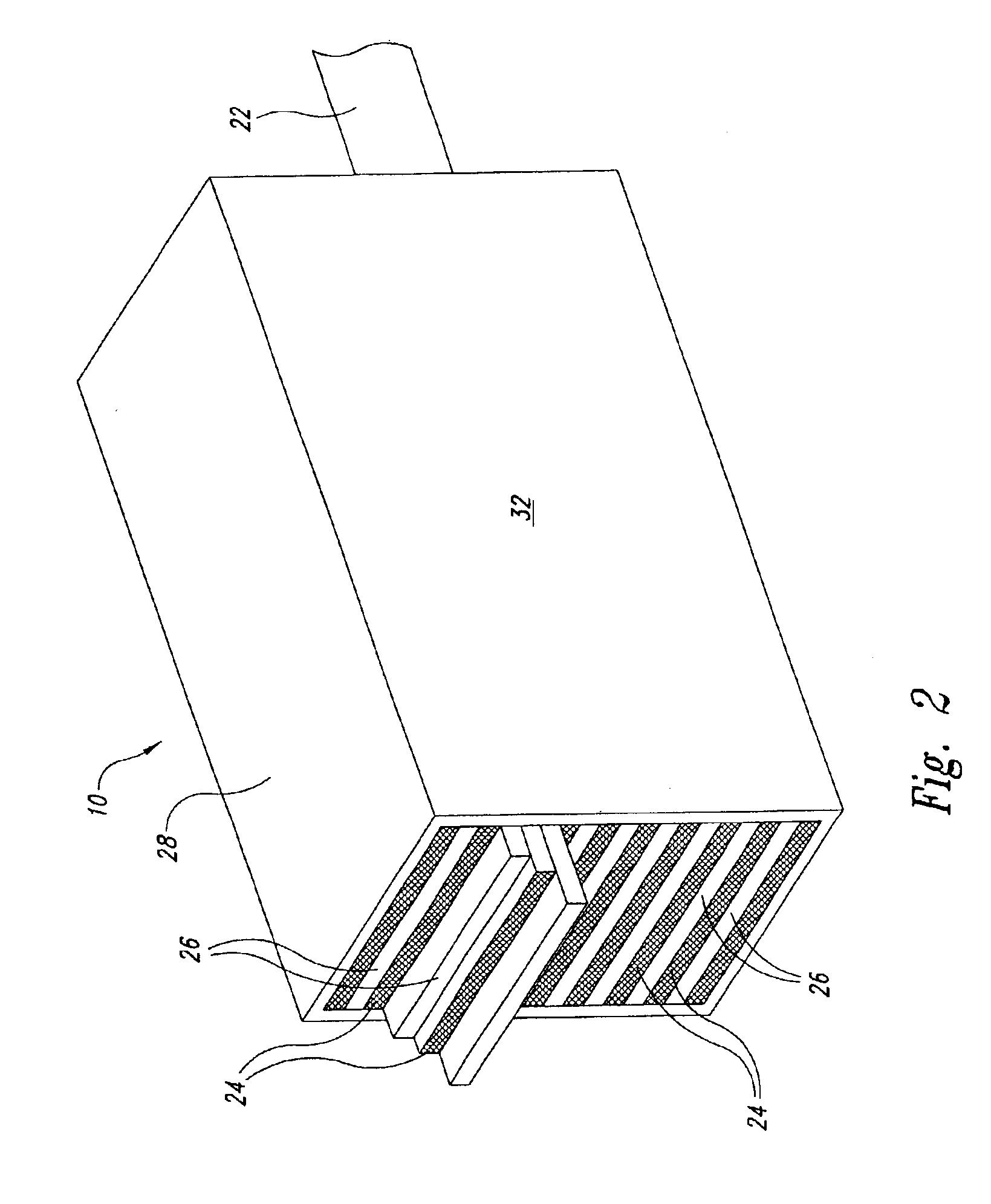

Pressure containing heat transfer tube and method of making thereof

InactiveUS20050067156A1Stationary conduit assembliesHeat exchanger casingsMeet in the middleEngineering

A heat transfer tube and a method of forming a heat transfer tube with indents formed in the opposed walls. The indents may be cold welded or forge welded such that dimples or indentations meet in the middle of the tube. The bottom of a first indentation disposed on a first side of the tube is welded to the bottom of a second indentation formed in the opposite side of the tube.

Owner:OUTOKUMPU OY

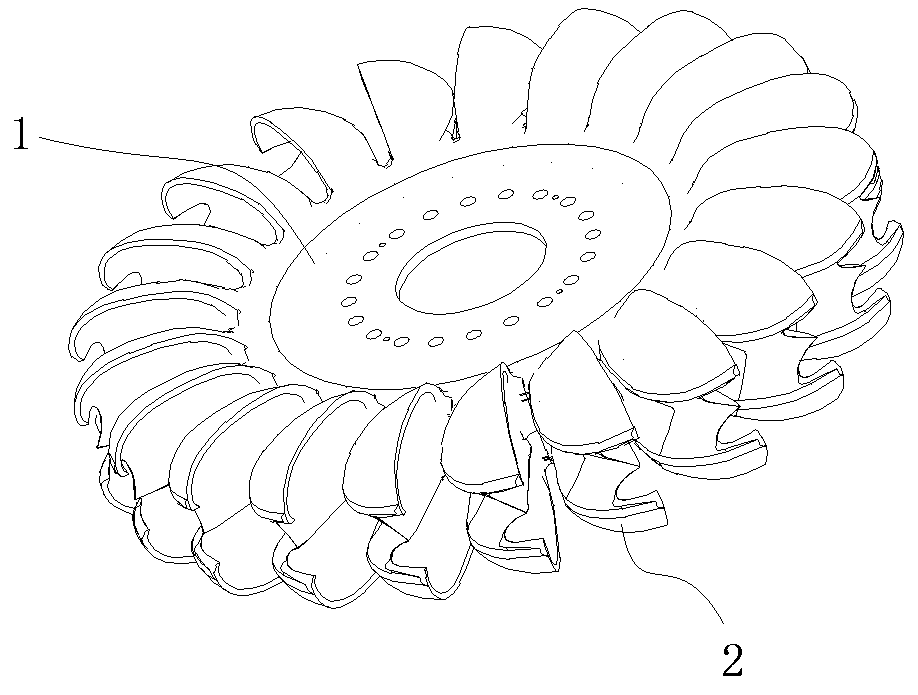

Composite gas turbine discs for increased performance and reduced cost

ActiveUS20060008352A1Reduce manufacturing difficultyReduce alloy costTurbinesBlade accessoriesNickel alloyTurbine

A composite turbine disc includes a high nickel rim section and a steel bore section. The rim section is formed from a high nickel alloy which provides a higher melting point as compared to the material used for the bore section. A plating or forged welding enhanced agent layer is disposed between the bore section and rim section. Composite disc can be formed by forging the rim and bore material together, or by welding the rim and bore material together.

Owner:SIEMENS ENERGY INC

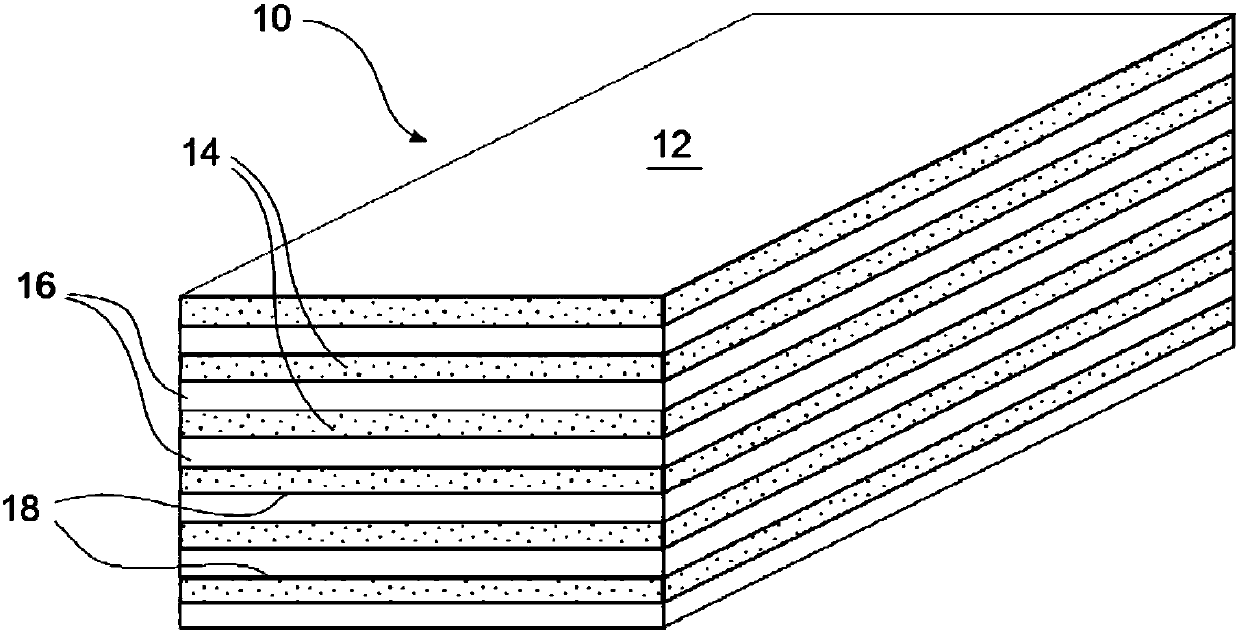

Metal lamination method and structure

A method of forge welding laminates of titanium and titanium alloys includes interleaving first and second pluralities of metal pieces in an enclosure, filling the enclosure with an inert gas, heating the enclosure and the first and second pluralities of metal pieces, and mechanically pressing the enclosure on a first axis with a force sufficient to cause the first and second pluralities of metal pieces to forge-weld together. The first and second pluralities of metal pieces may be metallurgically dissimilar from each other, and may each comprise a percentage of titanium.

Owner:ALPHA KNIFE SUPPLY LLC +3

Forming method for sandglass-shaped metal structure

The invention discloses a forming method for a sandglass-shaped metal structure. The forming method is characterized by comprising the following steps: preparing a plurality of elements; stacking theplurality of elements together to form a shape having a cross section area which is gradually increased from the middle to the two ends; welding and packaging the plurality of elements which are stacked together into a preform; and welding interferences among the plurality of elements together through forge welding to prepare a blank from the preform. According to the forming method disclosed by the invention, a plurality of metal blanks with smaller sizes are used as structure elements for preparing a large metal blank.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Composite gas turbine discs for increased performance and reduced cost

A composite turbine disc includes a high nickel rim section and a steel bore section. The rim section is formed from a high nickel alloy which provides a higher melting point as compared to the material used for the bore section. A plating or forged welding enhanced agent layer is disposed between the bore section and rim section. Composite disc can be formed by forging the rim and bore material together, or by welding the rim and bore material together.

Owner:SIEMENS ENERGY INC

Joining expandable tubulars

InactiveUS20050050726A1Fluid removalHigh frequency current welding apparatusEngineeringForge welding

A method of joining expandable tubulars includes joining the tubulars by forge welding and flushing a reducing flushing gas around the heated tubular ends during at least part of the forge welding operation such that oxides are removed from the forge welded tubular ends and the amount of irregularities between the forge welded tubular ends is limited.

Owner:SHELL OIL CO

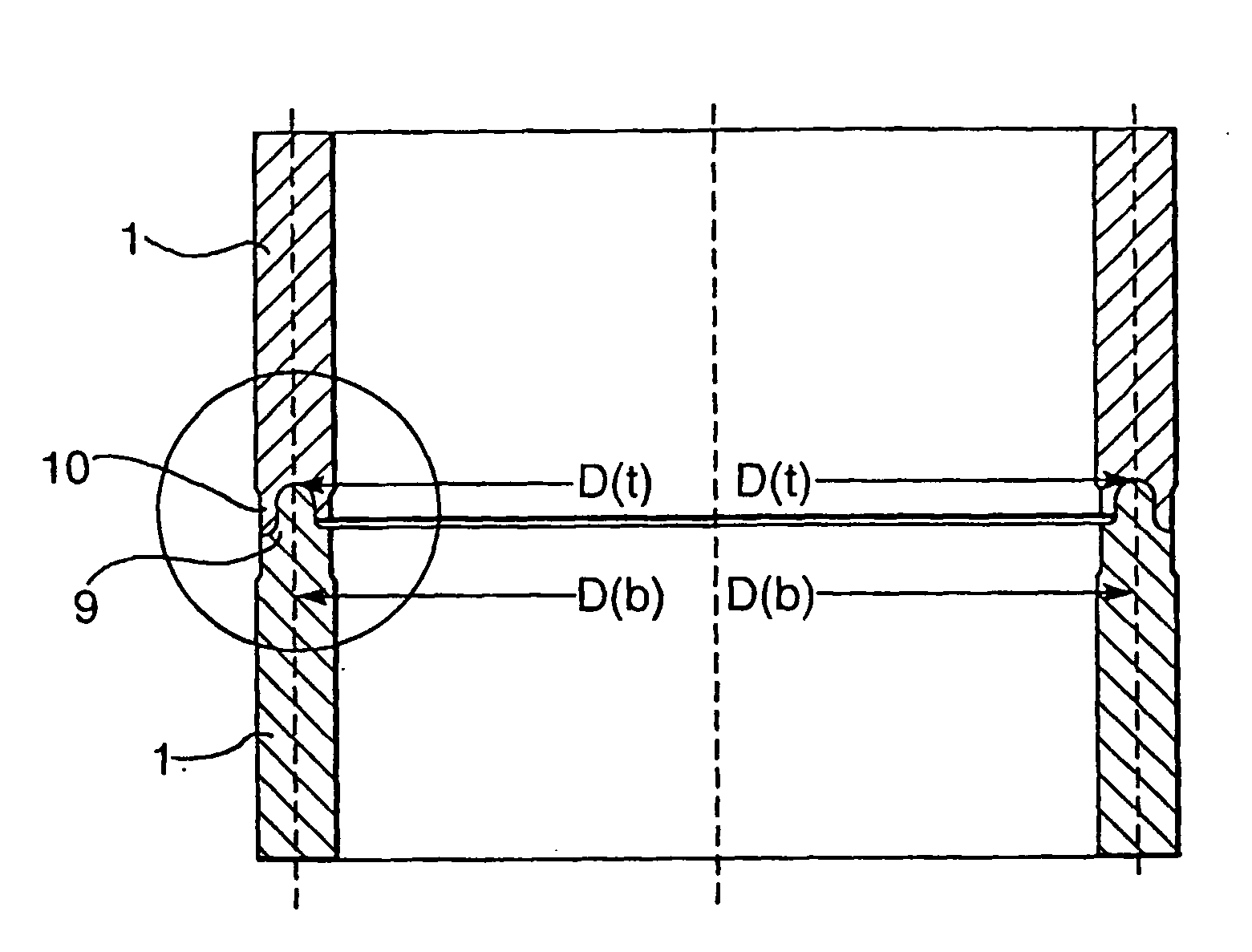

Forge welding of heavy duty tubulars

InactiveUS20060169752A1Avoid shear stressHigh frequency current welding apparatusWelding/cutting media/materialsPipe fittingEngineering

A method of joining heavy duty oilfield, well, or other tubulars includes the step of joining the tubulars by forge welding and flushing a reducing flushing gas around the heated tubular ends during at least part of the forge welding operation such that oxides are removed from the forge welded tubular ends and the amount of oxide inclusions and irregularities between the forge welded tubular ends is limited. The tubular ends may have a teethed sinusoidal or other non-planar shape to inhibit any abrupt variations of the wall strength in the welding area and / or to reduce shear forces to the forge weld when the tubulars are twisted and / or radially expanded.

Owner:SHELL OIL CO

Vibrating casting and forging composite forming method for aluminum alloy forgings

ActiveCN106312016AHigh densityIncrease profitMetal-working apparatusMolten stateVolumetric Mass Density

The invention provides a vibrating casting and forging composite forming method for aluminum alloy forgings and belongs to an aluminum alloy forging machining method. The vibrating casting and forging composite forming method for the aluminum alloy forgings solves the problems that by means of an existing casting and forging composite forming technology, the forging penetration is poor and the microdefect compaction effect is poor due to one-time compaction in the forging process, so that the forging defects are eliminated, and the forging performance is improved. The vibrating casting and forging composite forming method comprises the steps of alloy smelting, extrusion casting and vibrating die forging. By the adoption of the vibrating casting and forging composite forming method, the advantage that the forming performance of an aluminum alloy in the molten state is good and the advantage that through vibrating die casting, grains can be refined effectively and the density of the forgings is increased are combined; microdefect compaction during the casting process is promoted through high-pressure extrusion casting, the impact heating and stress wave superposition effect is generated through high-frequency vibration and compaction, the forging penetration is improved, the compaction and forge welding of the defects during the forging process are promoted, and the mechanical property is improved; and the vibrating casting and forging composite forming method has the beneficial effects that the technological process is short, the material utilization rate is high, energy is saved and the equipment investment is small and is especially suitable for forming of the complex aluminum alloy forgings of automotive steering knuckle control arms and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Constructing-and-forging method for preparing homogenized forged pieces

ActiveUS20180078995A1Good composition uniformityImprove compactnessWelding/cutting auxillary devicesCleaning using toolsHeating furnaceVacuum chamber

A constructing-and-forging method for preparing homogenized forged pieces comprises: preparing preformed billets: cutting off a plurality of continuous casting billets, milling and smoothing surfaces of the billets to be welded, performing vacuum plasma cleaning operation to the surfaces to be welded, stacking the plurality of billets and sealing around the surfaces in a vacuum chamber by electron beam welding; forge-welding and homogenizing the preformed billets: heating the preformed billets to a certain temperature in a heating furnace and taking the heated preformed billets out of the heating furnace, forging the preformed billets by a hydraulic press, then using three-dimensional forging to disperse the welded surfaces such that composition, structure and inclusion of the interface areas are at the same level as those of the bodies of the billets. Cheap continuous casting billets are stacked and forge welded.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

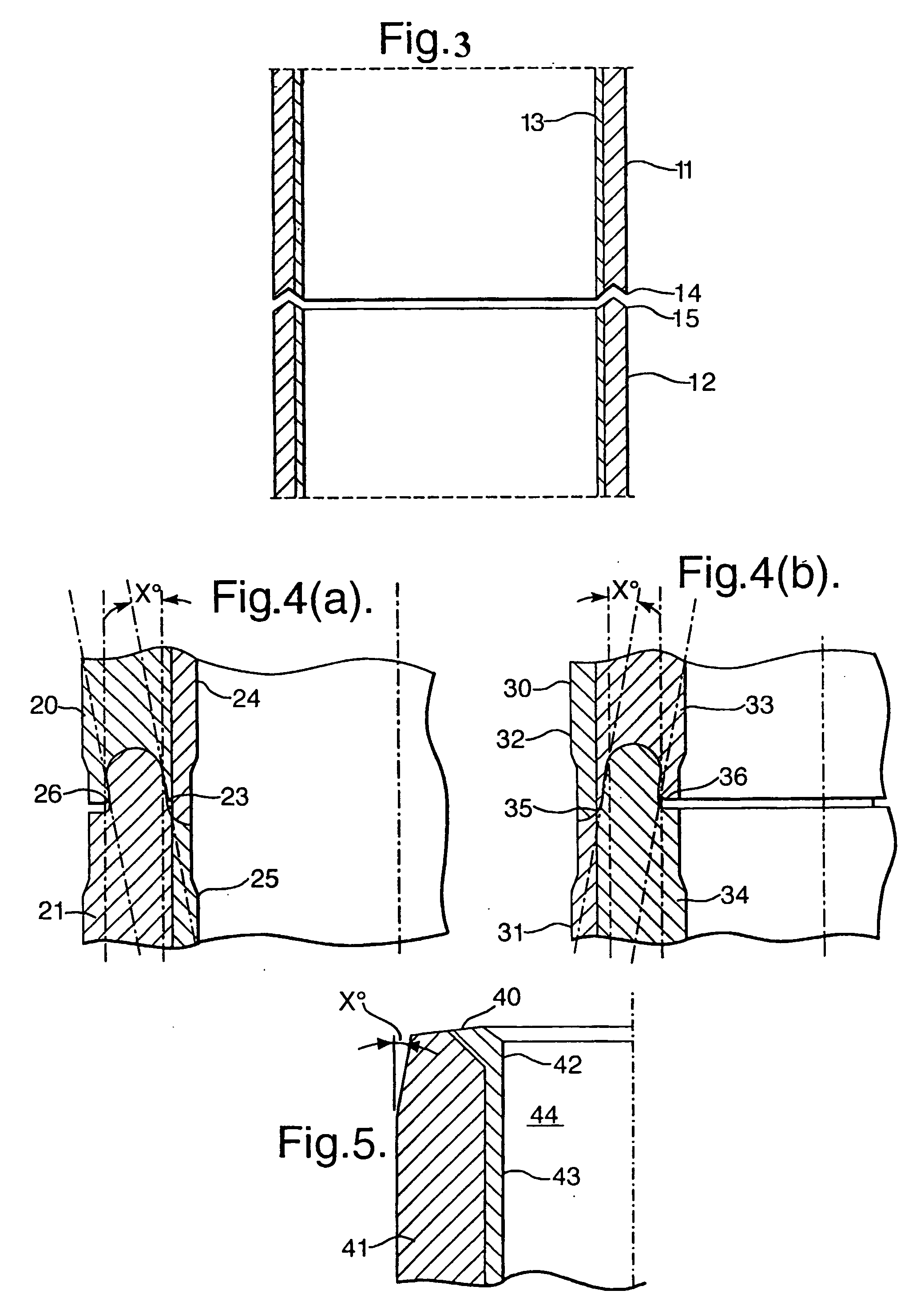

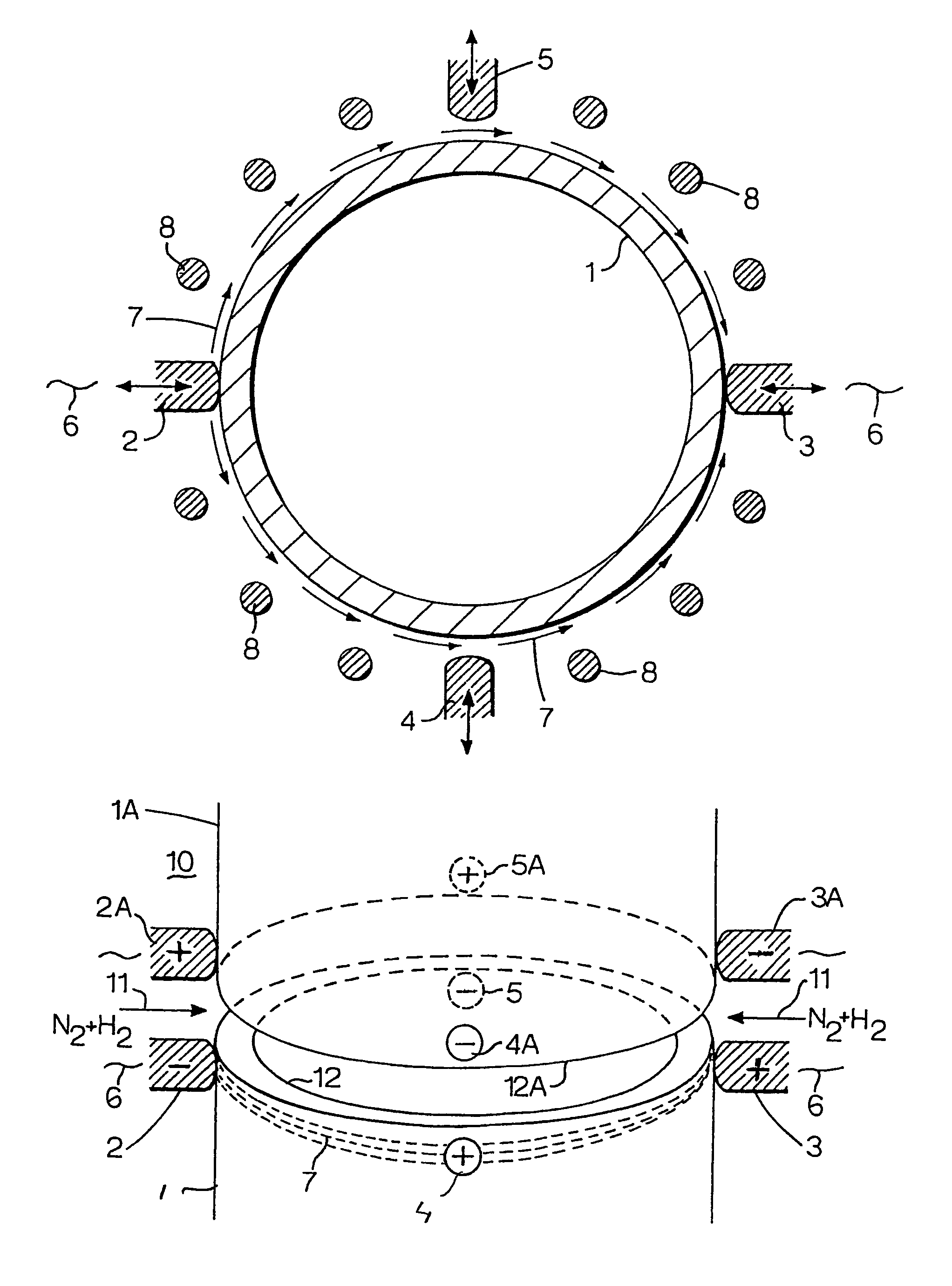

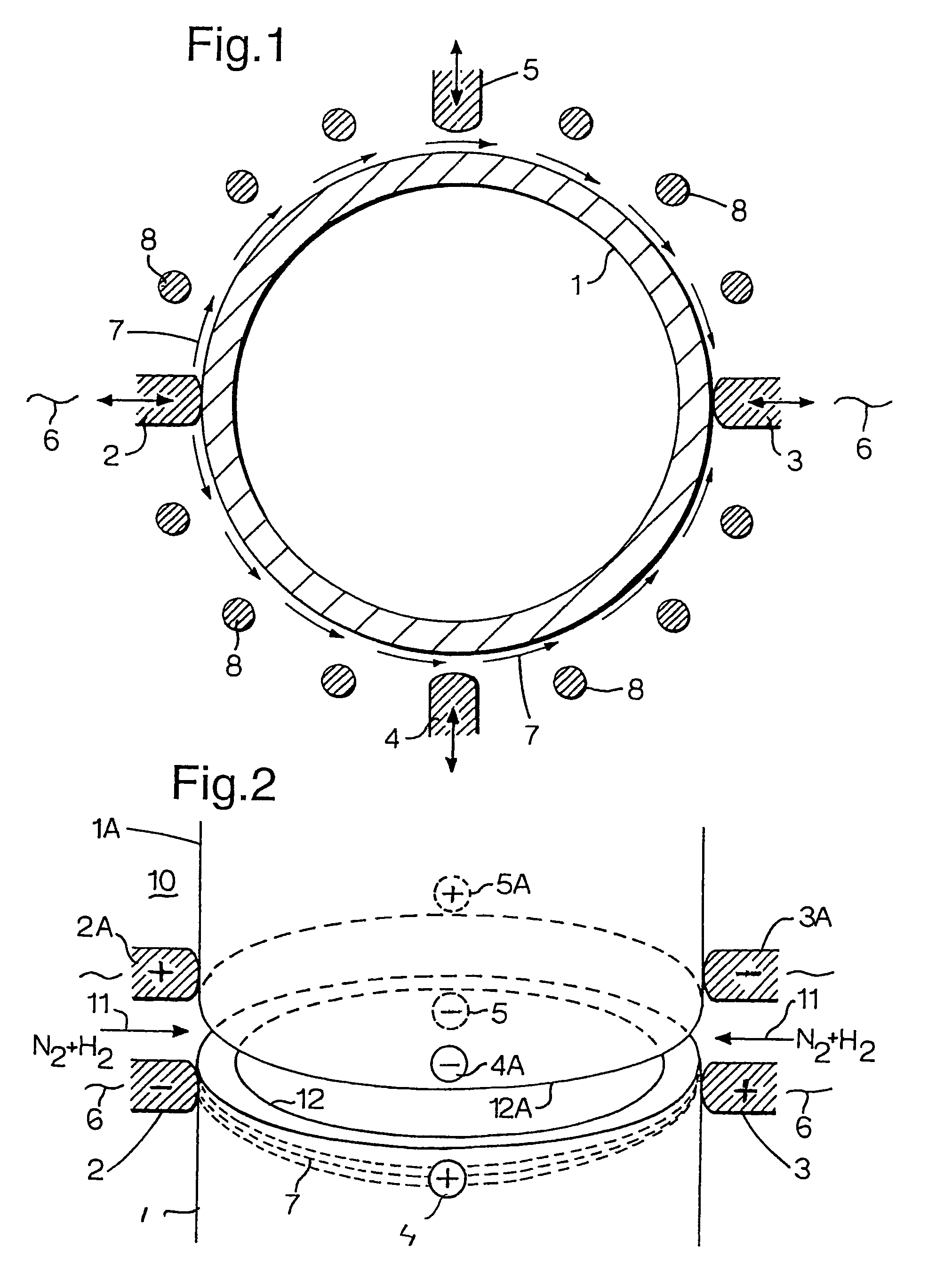

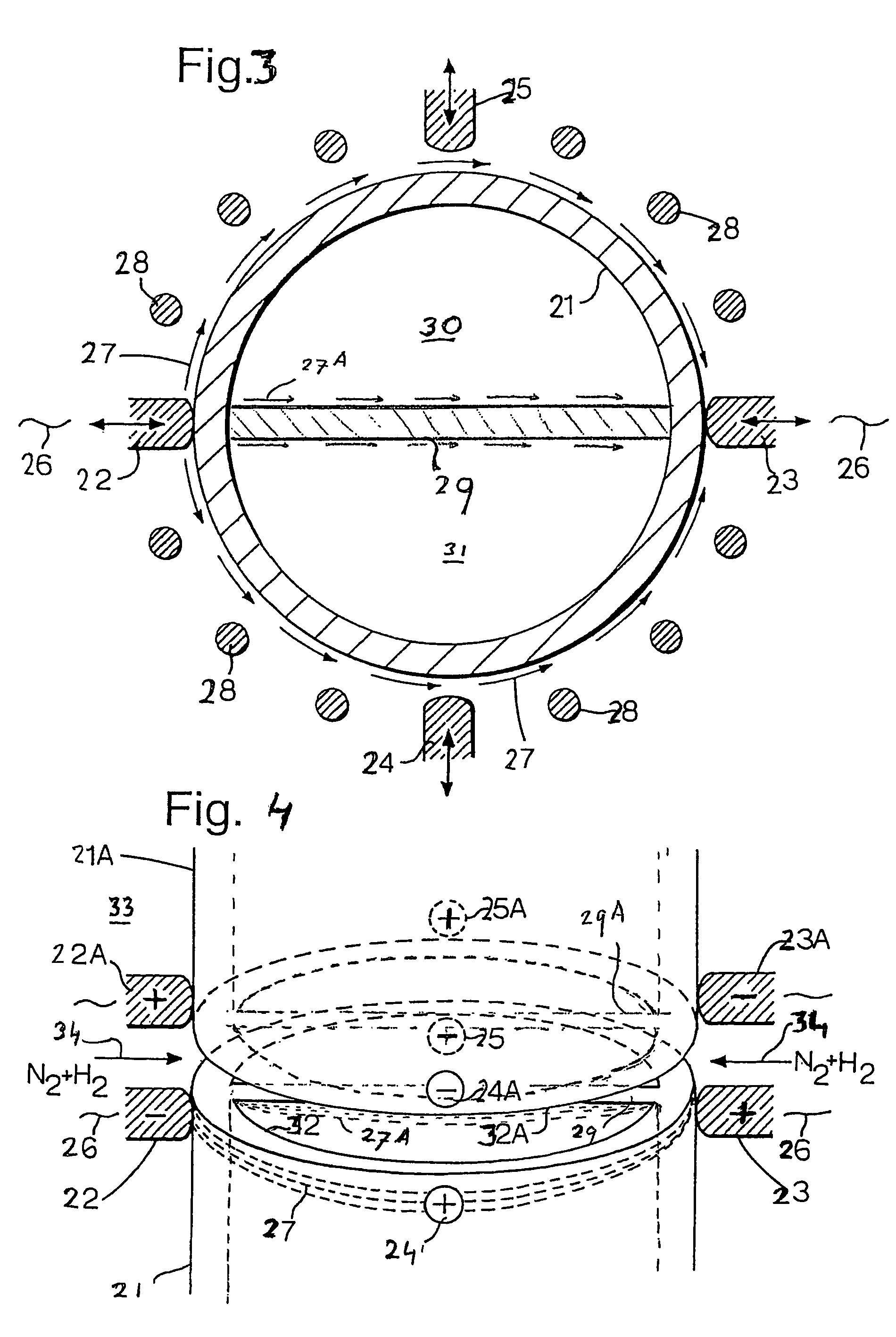

Method for interconnecting tubulars by forge welding

InactiveUS20050092715A1Reduces unequal heatingReduce heatHigh frequency current welding apparatusResistance welding apparatusPipe fittingCarbon Dioxide / Helium

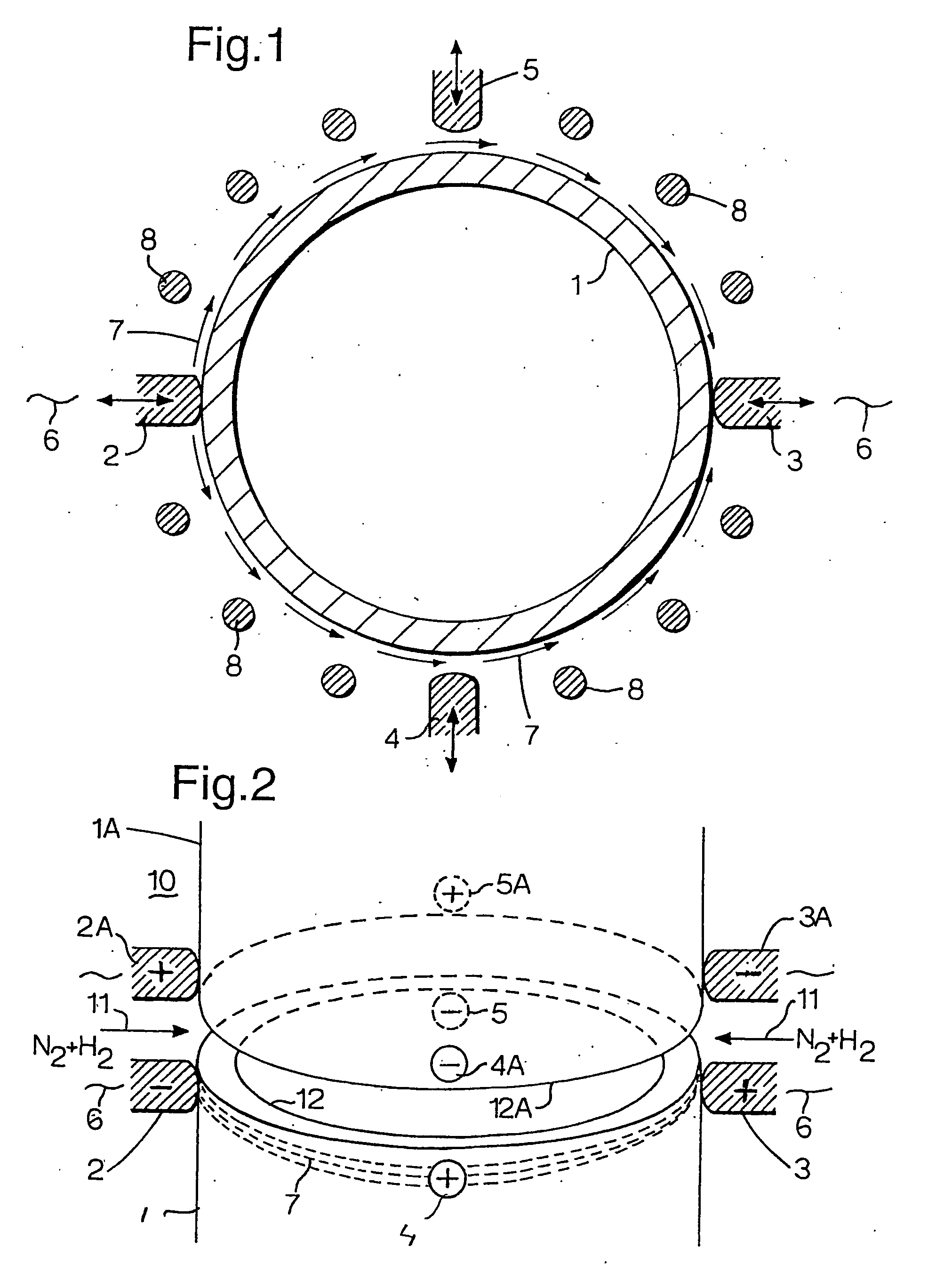

A method for interconnecting tubulars by forge welding involves arranging the tubular ends that are to be interconnected at a distance, up to a few millimeters from each other in a shield gas chamber, into which a reducing non-explosive flushing fluid mixture (e.g. N2+H2) is injected; heating each tubular end within the space by means of at least three electrodes that are pressed at circumferentially spaced intervals against the wall of each tubular, adjacent to the tubular end such that a high frequency electrical current is transmitted in a substantially circumferential direction through the tubular segments between the electrodes; and moving the thus uniformly heated tubular ends towards each other until a forge weld is formed between the heated tubular ends.

Owner:SHELL OIL CO

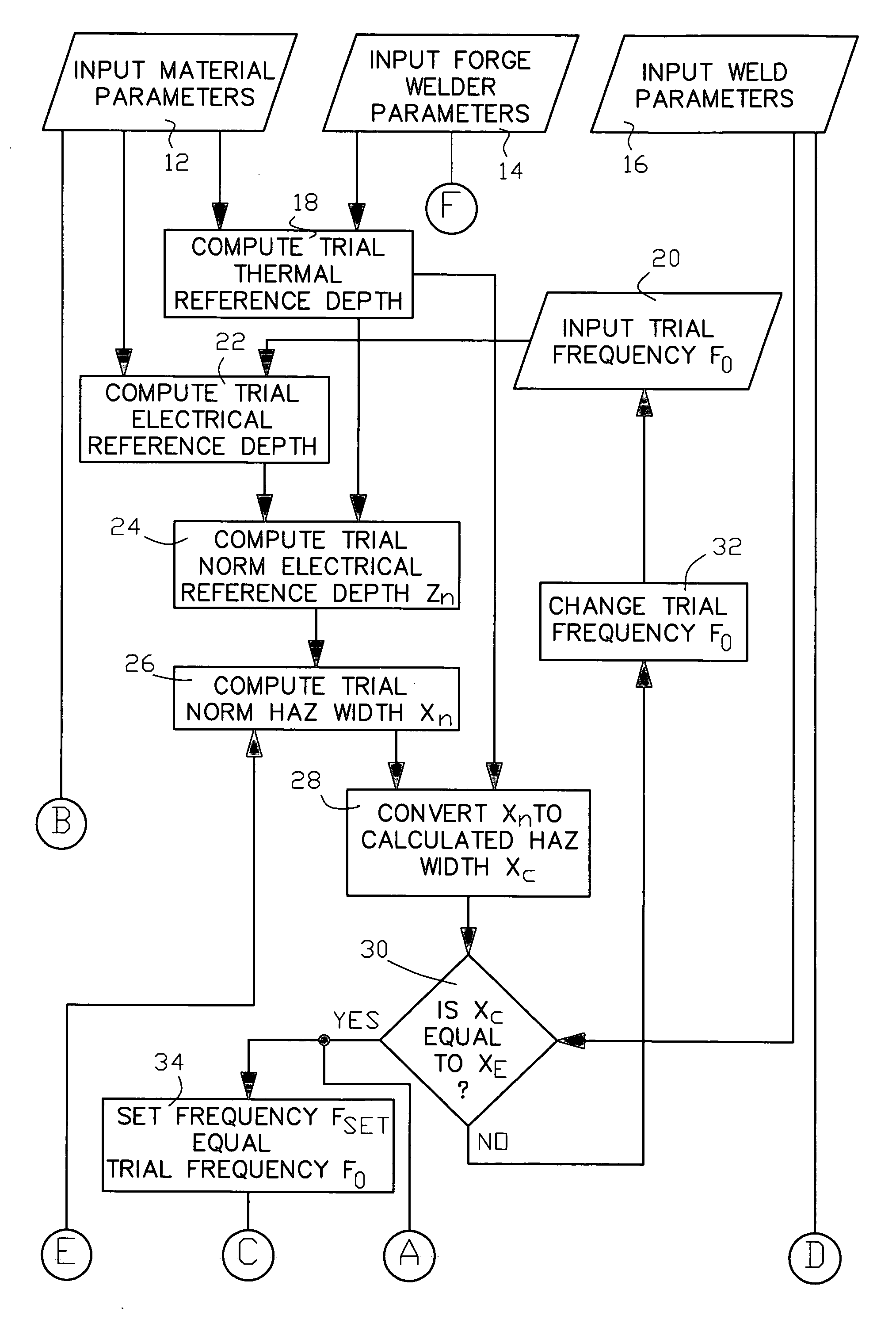

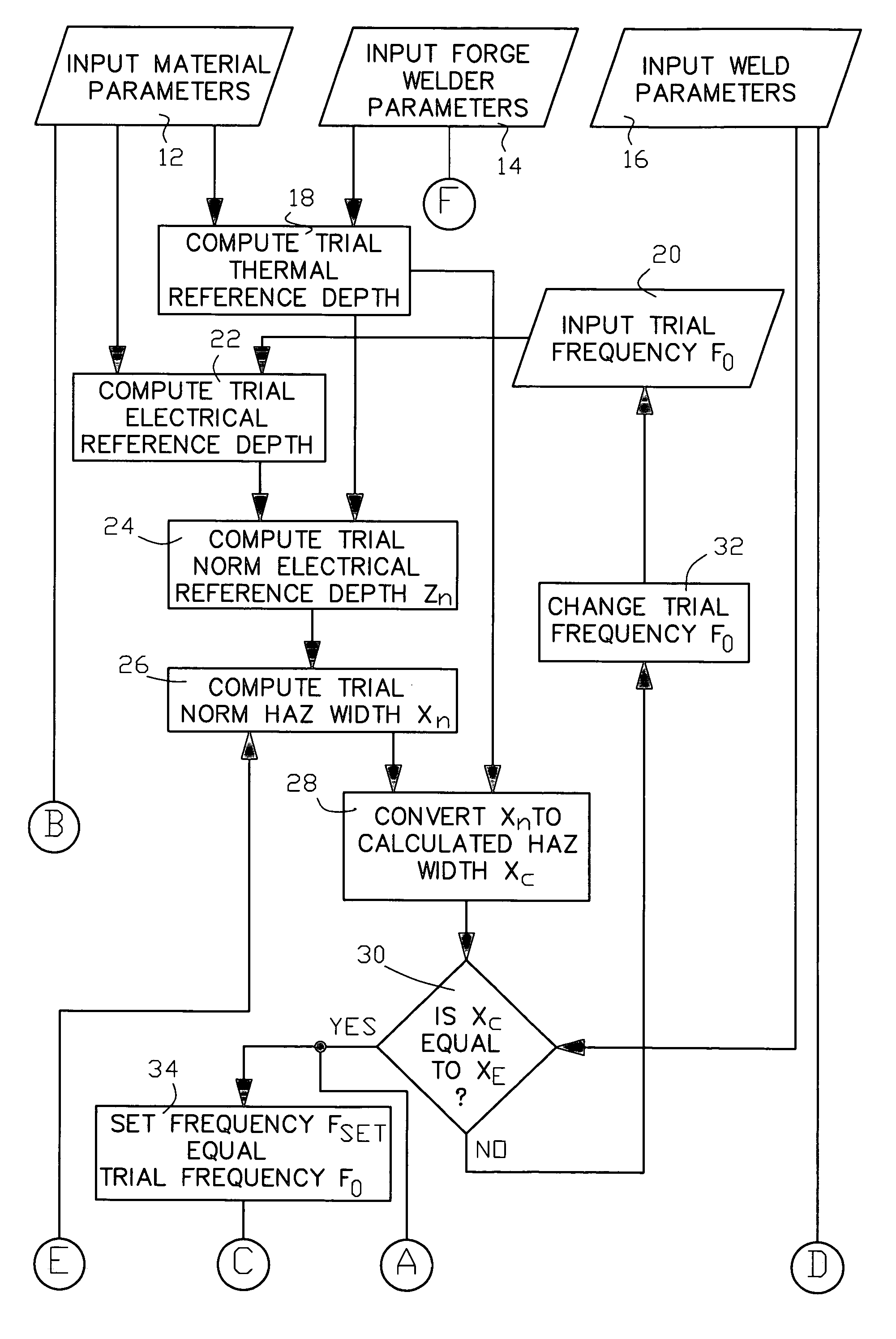

System and method of computing the operating parameters of a forge welding machine

ActiveUS20070034607A1High frequency current welding apparatusWelding/soldering/cutting articlesMulti materialHeat-affected zone

A system and method for computing the parameters of a forge welding machine for the forge welding of one or more materials is provided. A computer program executes a self-tuning routine to compute the operating frequency and operating power setting for the forge welding machine in response to an inputted width of the heat affected zone and an inputted weld temperature.

Owner:THERMATOOL

Method for preparing metal lamination material

ActiveCN107755878ASimple processFlexible processWelding/soldering/cutting articlesMetal working apparatusTitaniumForge welding

Owner:张颖

Sand-glass-shaped metal graded construction forming method

The invention discloses a sand-glass-shaped metal graded construction forming method. The sand-glass-shaped metal graded construction forming method is characterized in that firstly, a conventional construction method is used for carrying out first-stage construction, a workblank is obtained, and is subject to further forging to form a round table shape or square table shape to serve as a workblank element of the next-stage construction; N-stage construction is carried out, and two workblank elements are stacked together to form a sand glass shape on the whole body; the two workblank elementsstacked to be in the sand glass shape are packaged to a sand-glass-shaped prefabricated blank; through forging welding, the interface between the two workblank elements is welded to make the sand-glass-shaped prefabricated blank being the workblank; the workblank is further forged to form the round table or square table shape to serve as an N+1 stage constructed workblank element; the above stepsare repeated so as to achieve multi-stage construction, and the larger workblank is made. Due to the fact that the middle of the sand glass shape is small, the upper end and the lower end are large insize, in the deformation process, the middle segment with the small size preferably deforms, and therefore under the small pressure, large deformation of the middle interface is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

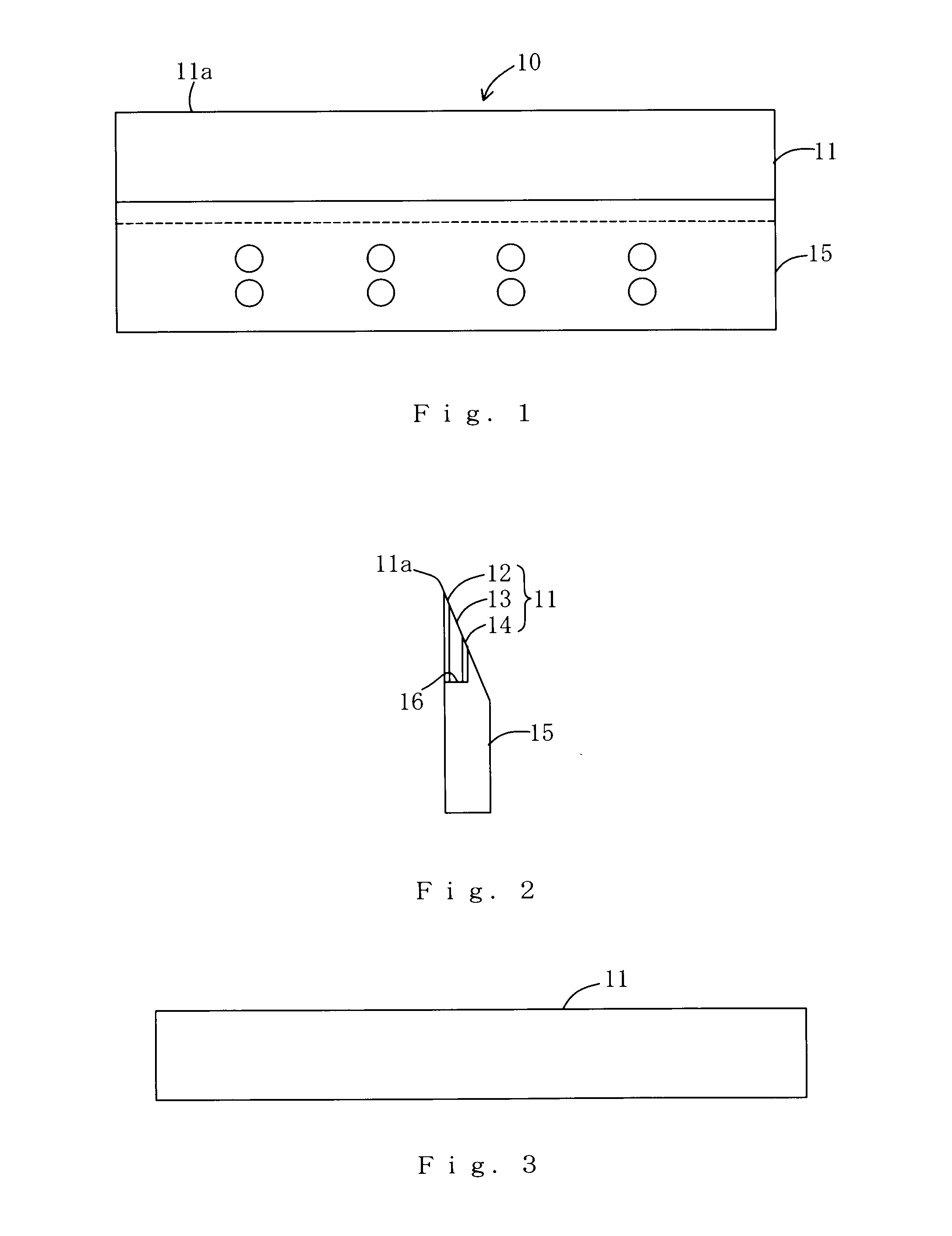

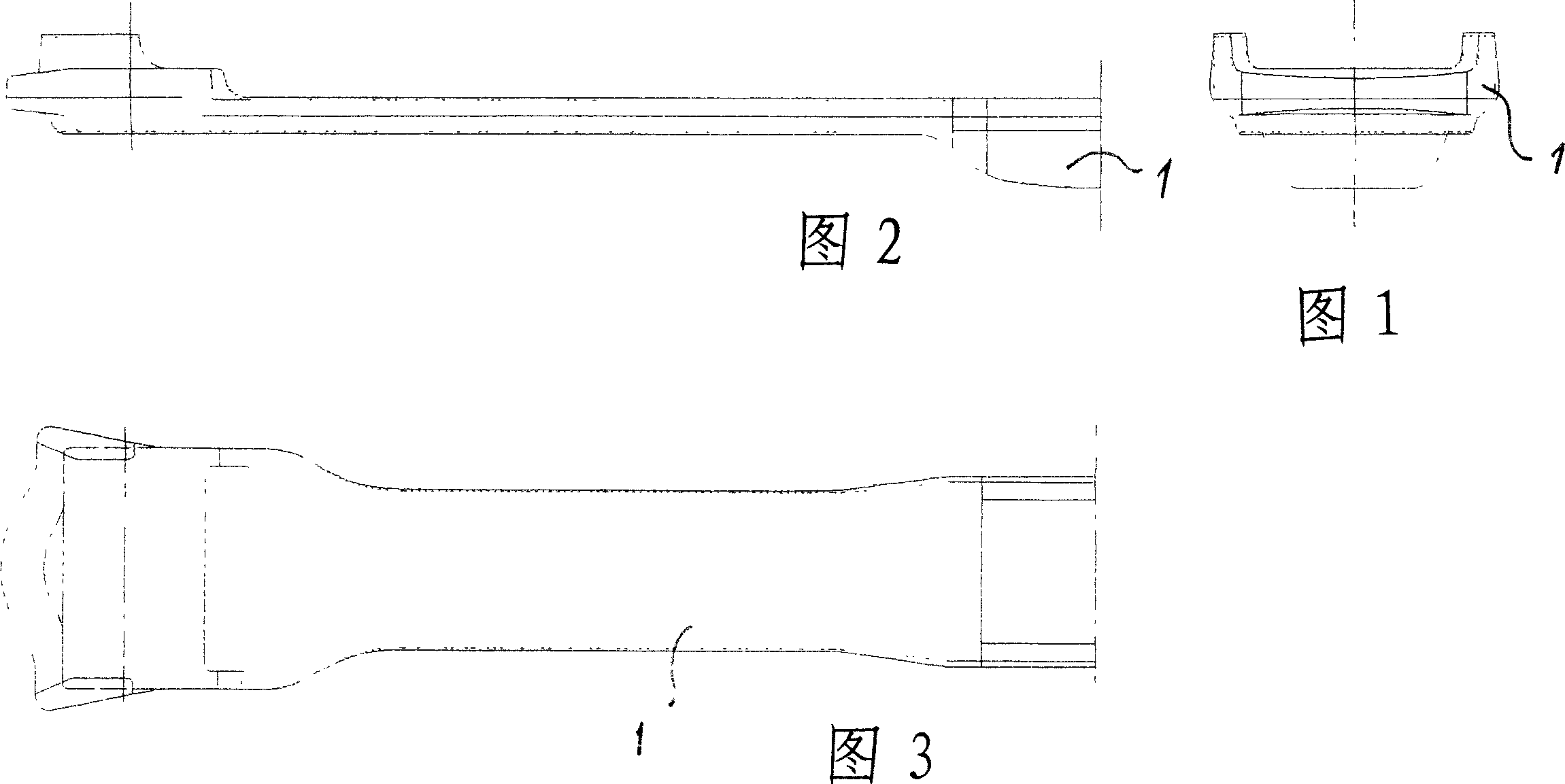

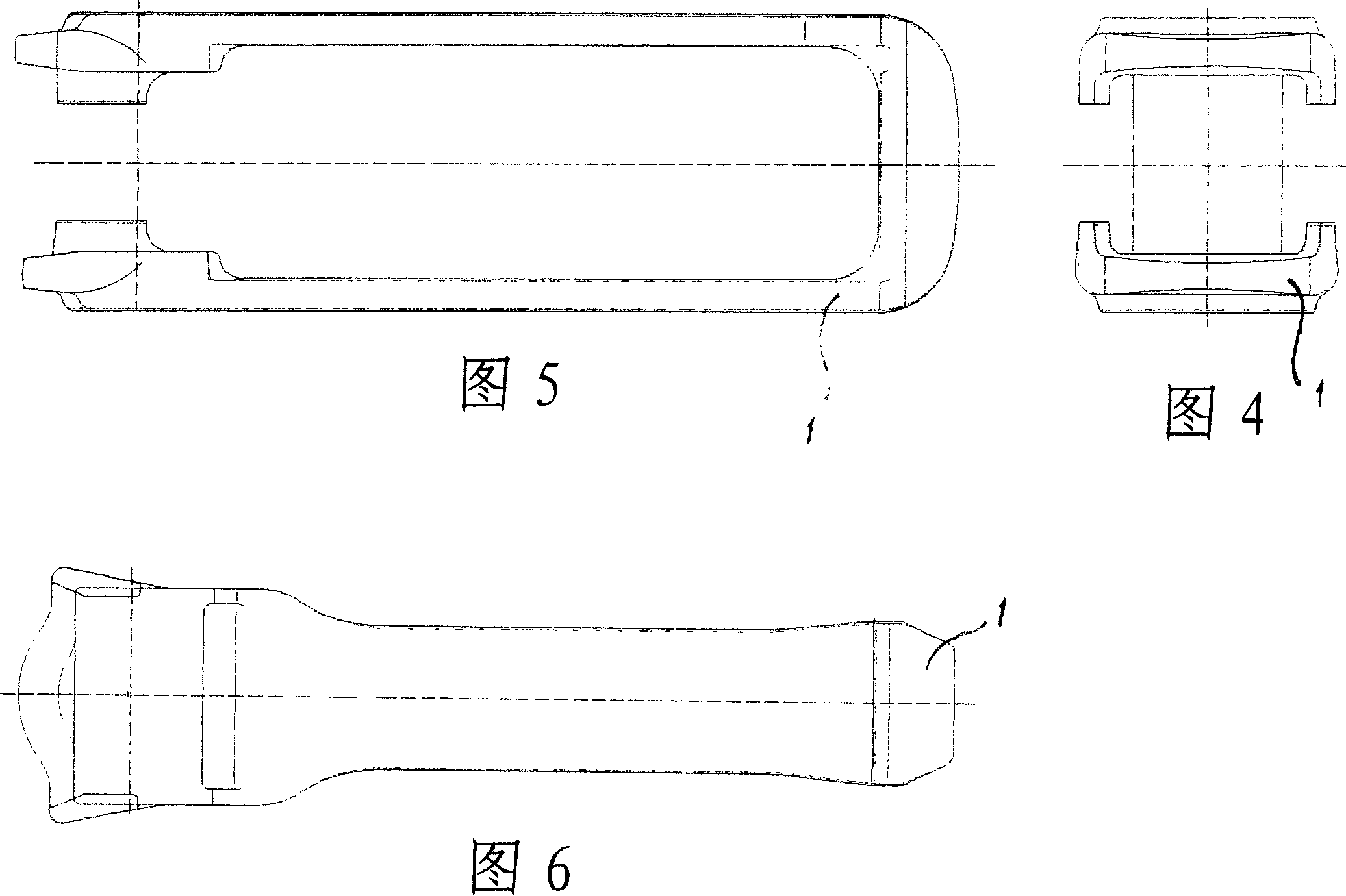

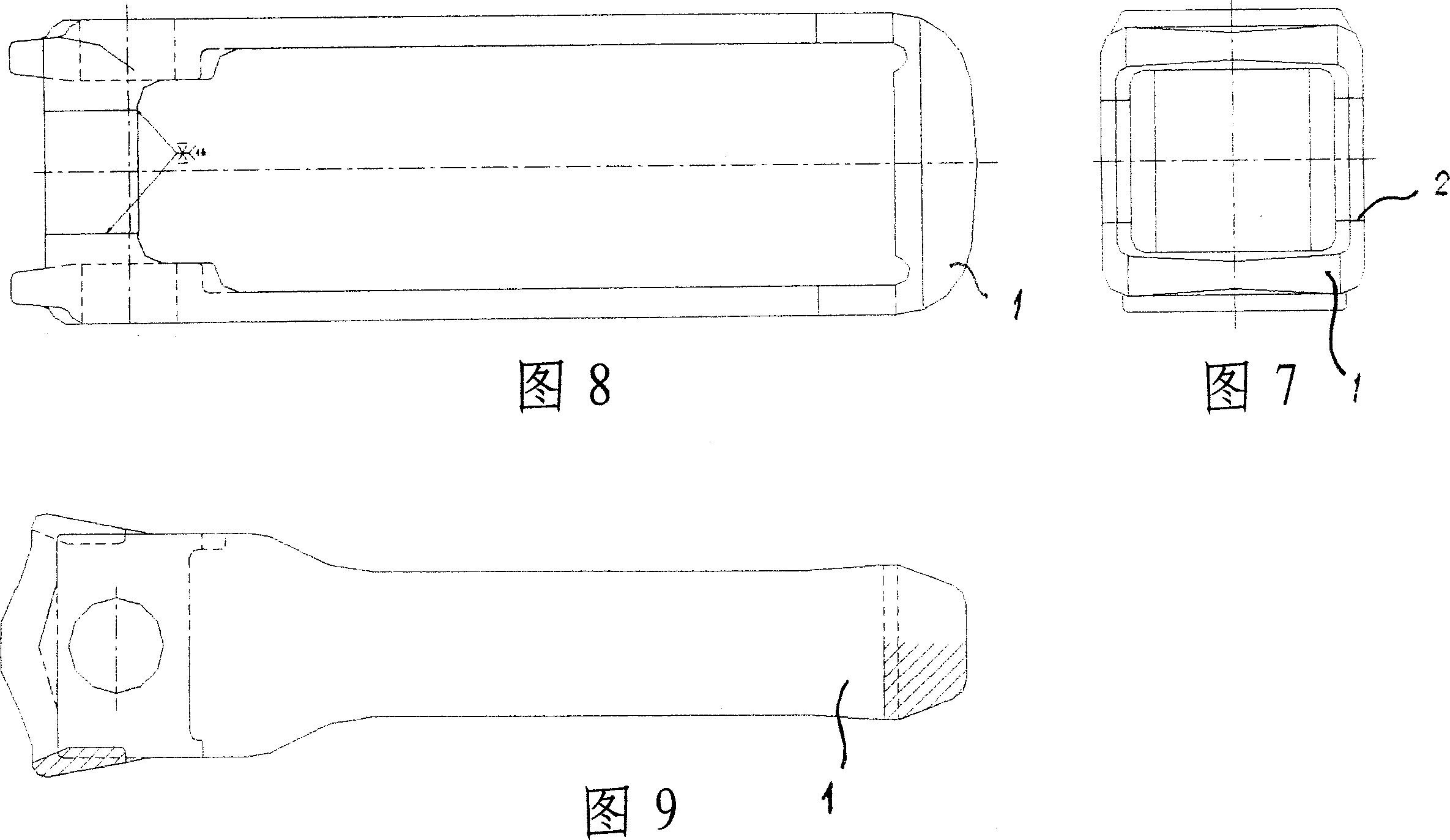

Flat cutting tool

InactiveUS20110030526A1High degree of precisionImprove stabilitySoldering apparatusMetal working apparatusSurface layerHardness

A flat cutting tool includes a blade member fixed to a mounting concavity of a base member using a brazing filler metal or an adhesive agent to form a cutting edge on a surface layer side of the blade member. The blade member includes a surface layer which is a high-speed tool steel with a high degree of hardness, a middle layer which is an alloy steel having a lower quench-hardenability than the high-speed tool steel, and a lower layer which is a mild steel having little quench-hardenability, which can be formed by forge welding. The blade member can be quenched and tempered, and the surface layer hardened to a hardness suitable for the cutting tool and fixed to the mounting concavity of the base member.

Owner:KANEFUSA HAMONO KOUGIYOU KK

Hydraulic self-operated three-way valve

ActiveCN102996852AFulfill action requirementsThe whole machine is simpleOperating means/releasing devices for valvesMultiple way valvesEngineeringHigh pressure

The invention relates to a three-way valve, in particular to a hydraulic self-operated three-way valve which belongs to the field of valves; the design of an overall structure of a hydraulic high-pressure inlet and outlet three-way valve is adopted; the action force of the pressure of a main pipeline medium serves as the driving force of the action of the valve through the structural design of a built-in piston cylinder; the action requirements of the valve can be met without adding other auxiliary driving devices, a problem that an external high-power driving device is needed is solved, and the overall valve is simplified. The valve body of the valve is in the design of an overall forged structure, so that the phenomenon that a forge welding structure has welding stress defects is avoided, and a 15NiCuMoNb5-6-4(WB36) material is adopted, so that the overall weight of the valve can be reduced by more than one third.

Owner:DALIAN DAGAO VALVE

Tubular assembly and method

InactiveUS20070075012A1Dispersed particle filtrationUsing liquid separation agentHydrogenEngineering

A tubular assembly and method for its manufacture is disclosed wherein an internal device is positioned and sealed in-line within a metal tube that is formed by two sections which are spin, inertia, or forge welded together so that the flash produced by the weld flows into the interior tube where the device is placed and the flash seals the device outer wall peripherally to the tube inner wall to form a gas tight seal. In a preferred embodiment the internal device is a gas filter for hydrogen gas.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

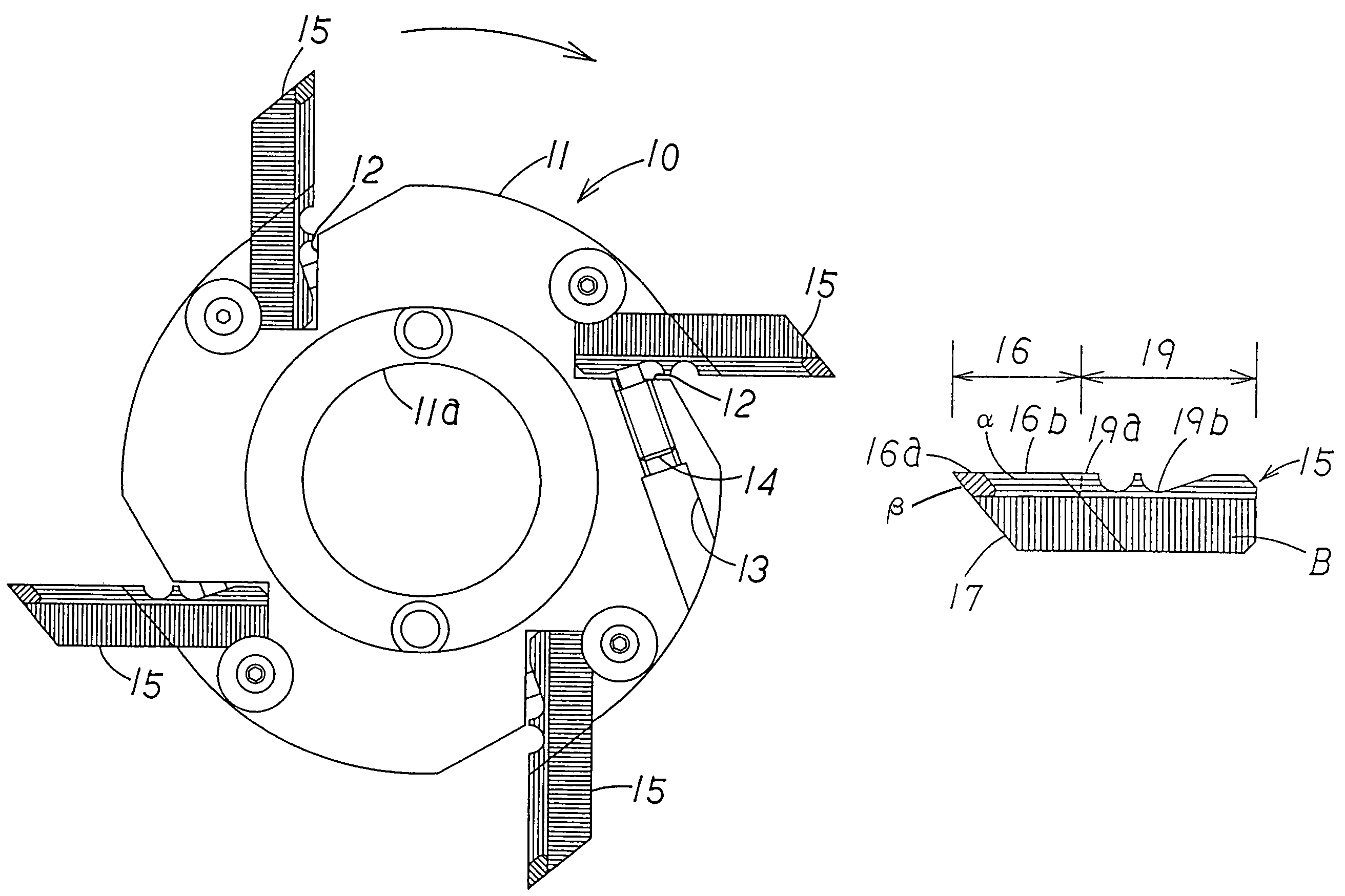

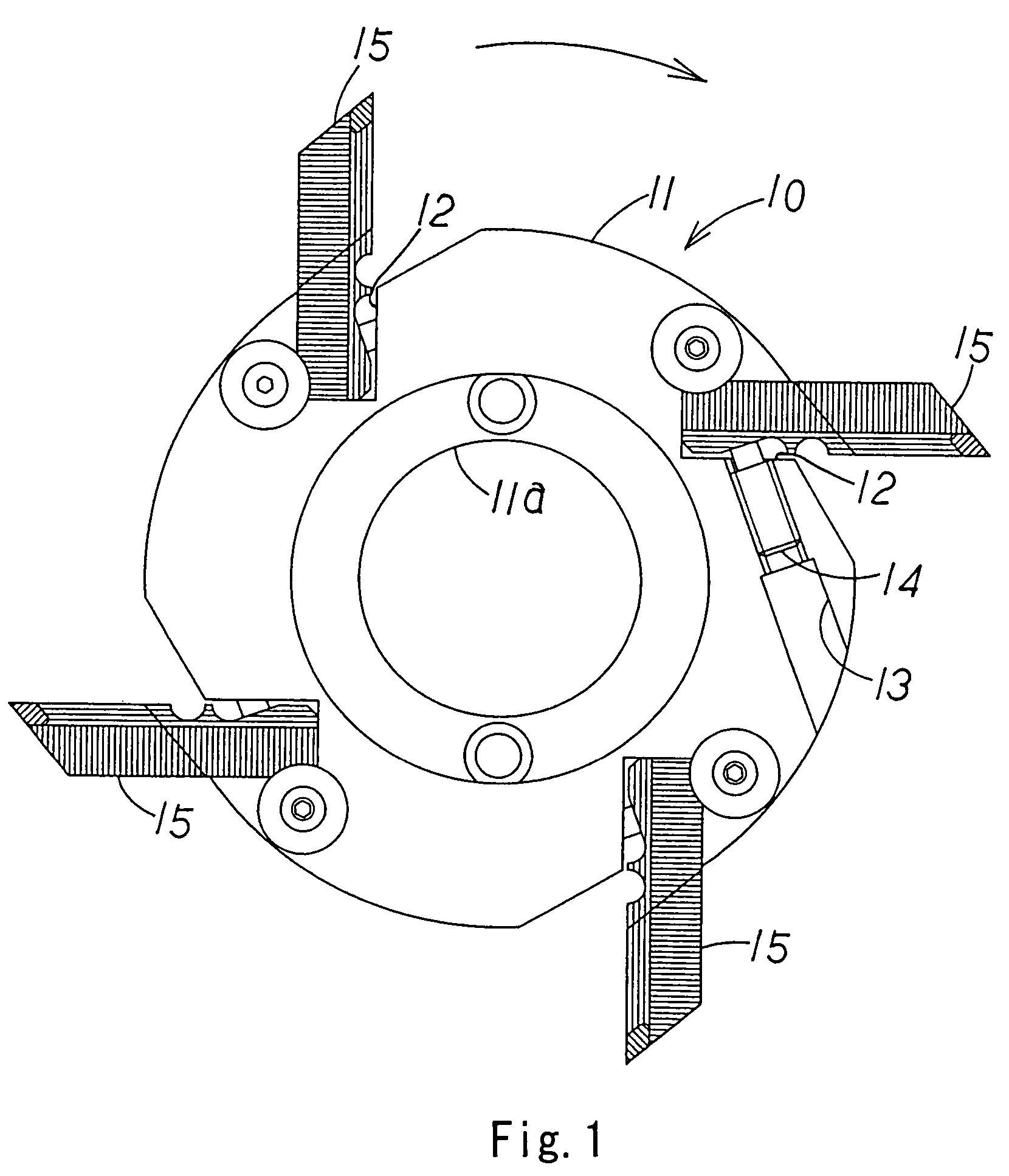

Finger cutter

InactiveUS7424900B2Restrict progress of wearHigh hardnessDovetailed workMulti-purpose machinesFinger jointHardness

Cutting portion regions of replaceable blades that extrude outward in a radial direction at a plurality of portions in a peripheral direction of an outer periphery of a body of a finger joint cutter are arranged in that, as for a cutting portion material that comprises cutting edge, tip end cutting portions are formed of a steel material of high hardness and base portion side cutting portions, which are the remaining portions, are formed of a steel material that exhibits a higher toughness than that of the tip end cutting portions. It is possible to improve the wear resistance through the tip end cutting portions and to improve the chipping resistance by the base portion side cutting portions. The steel material of high hardness comprising the tip end cutting portions and the steel material of high toughness comprising the base portion side cutting portions are successively joined through forge welding.

Owner:KANEFUSA HAMONO KOUGIYOU KK

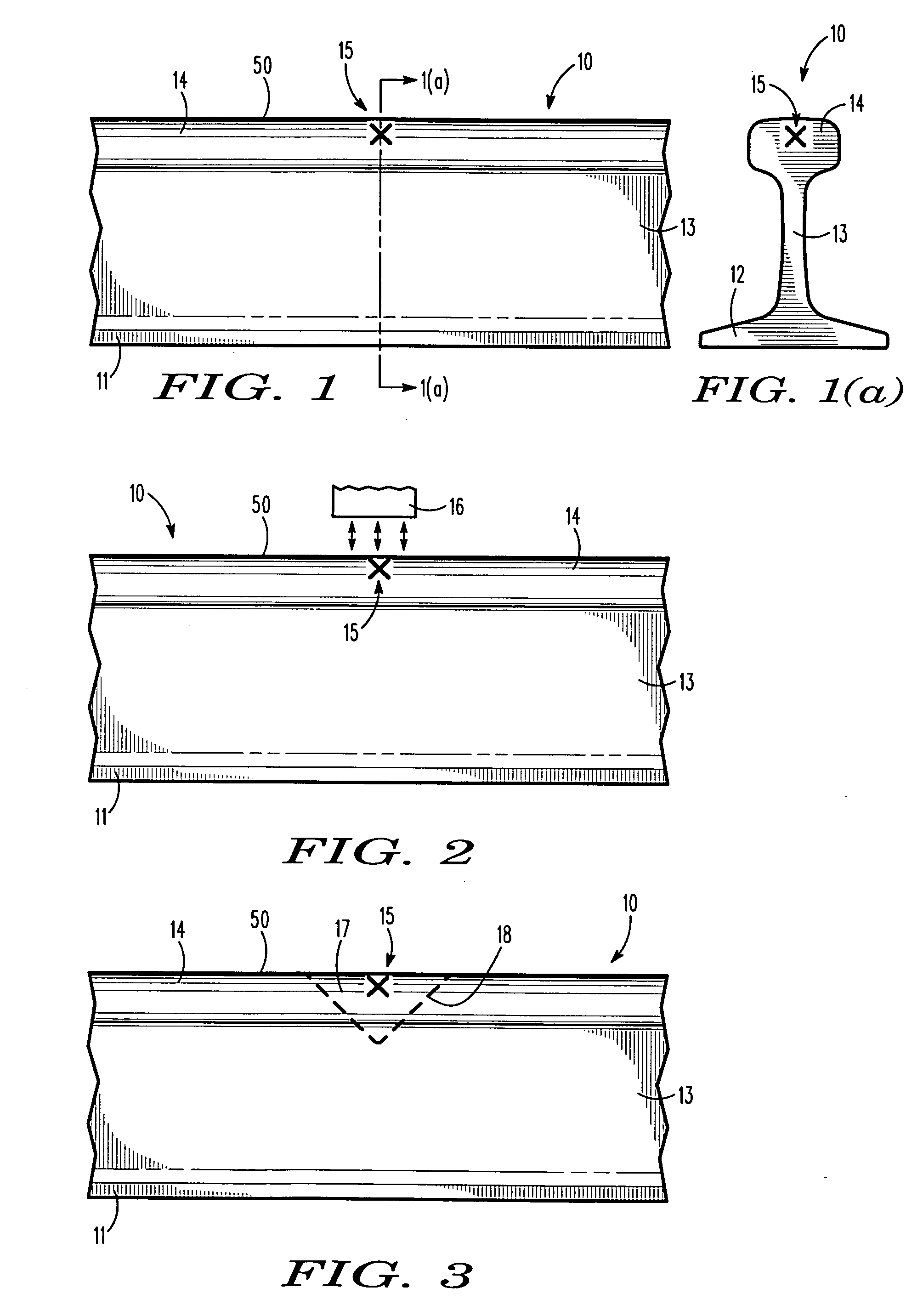

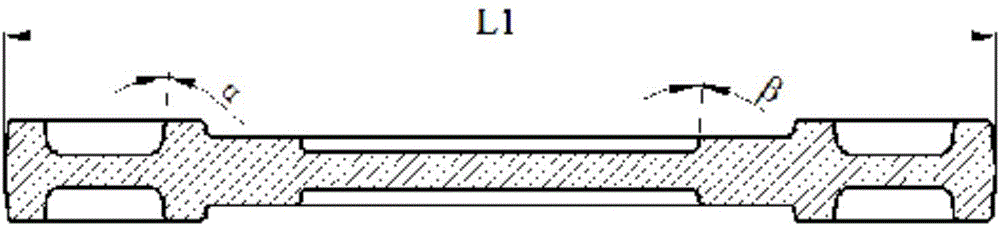

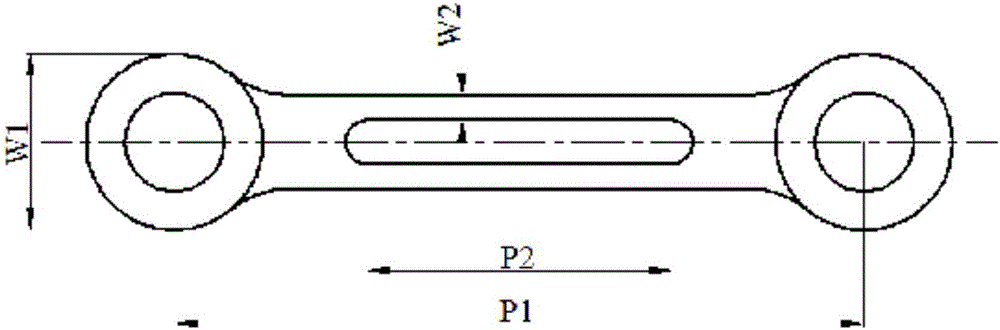

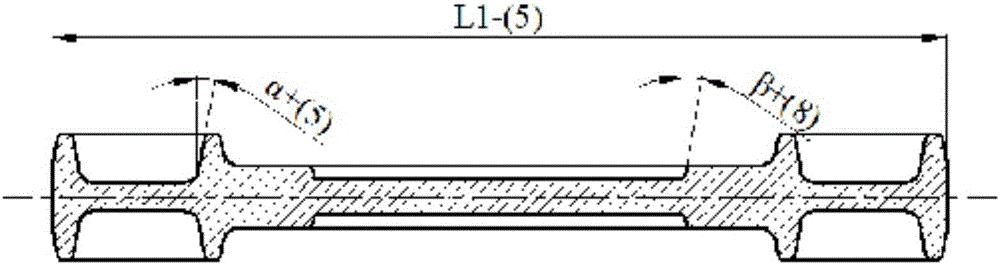

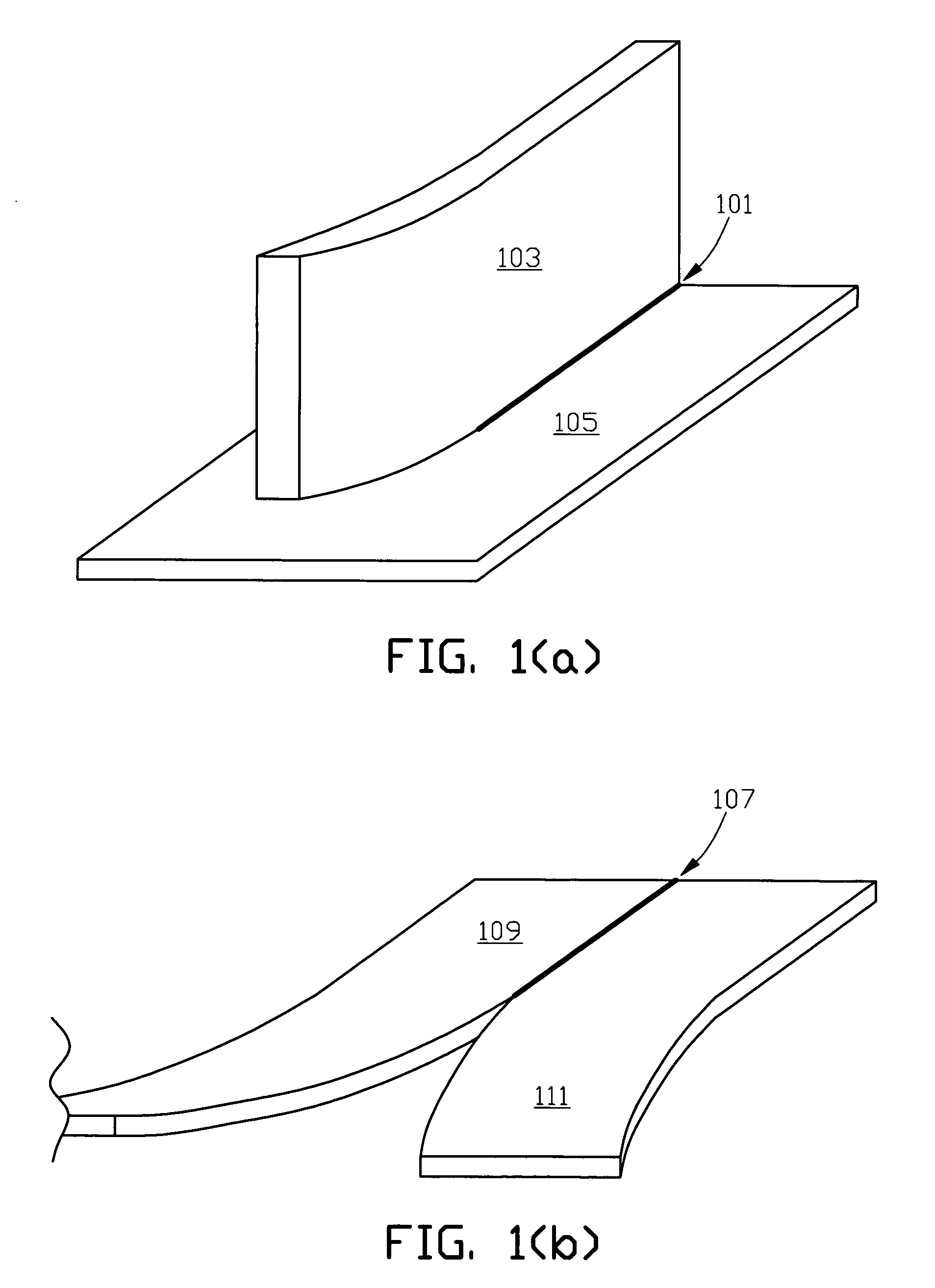

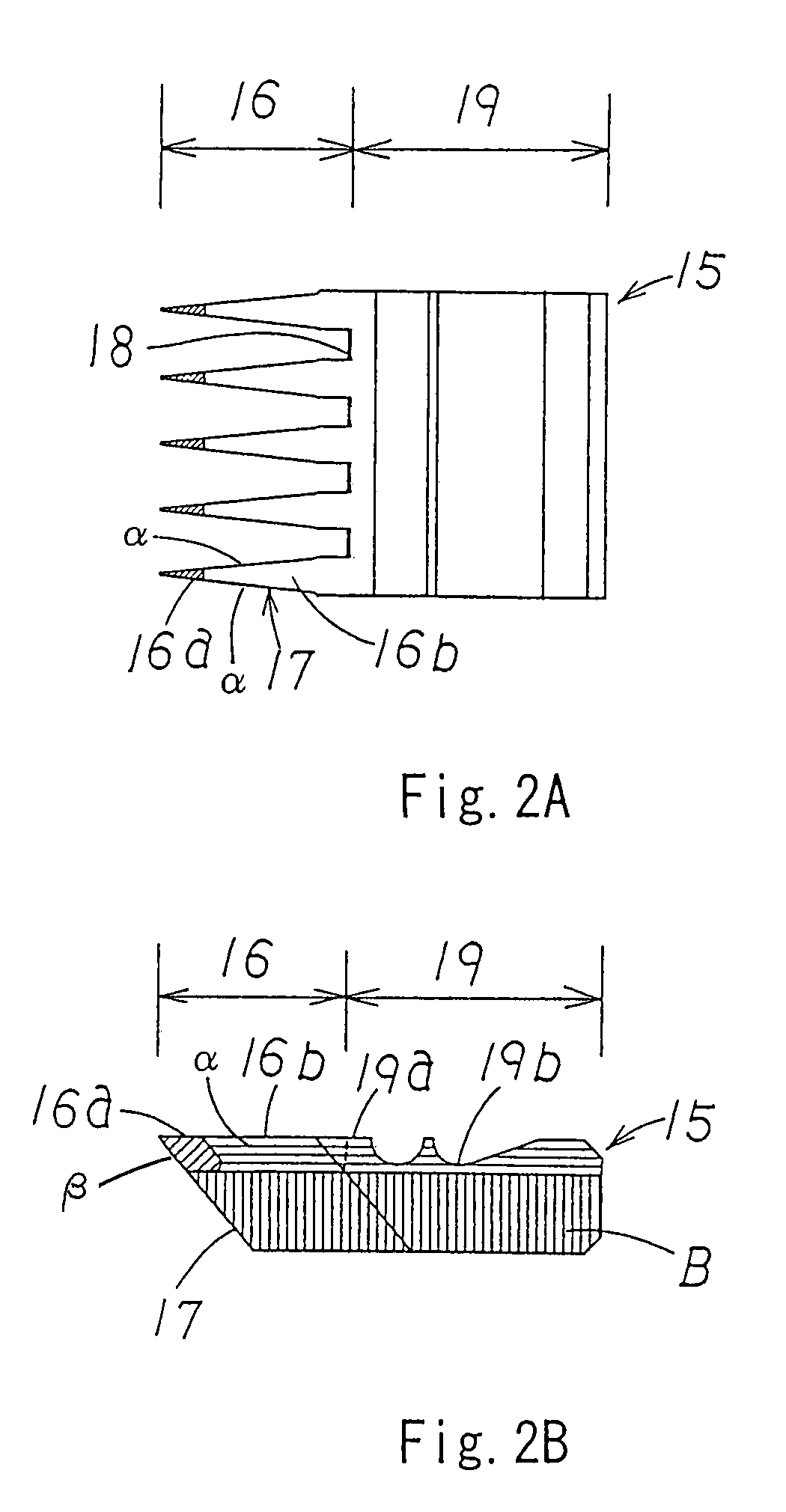

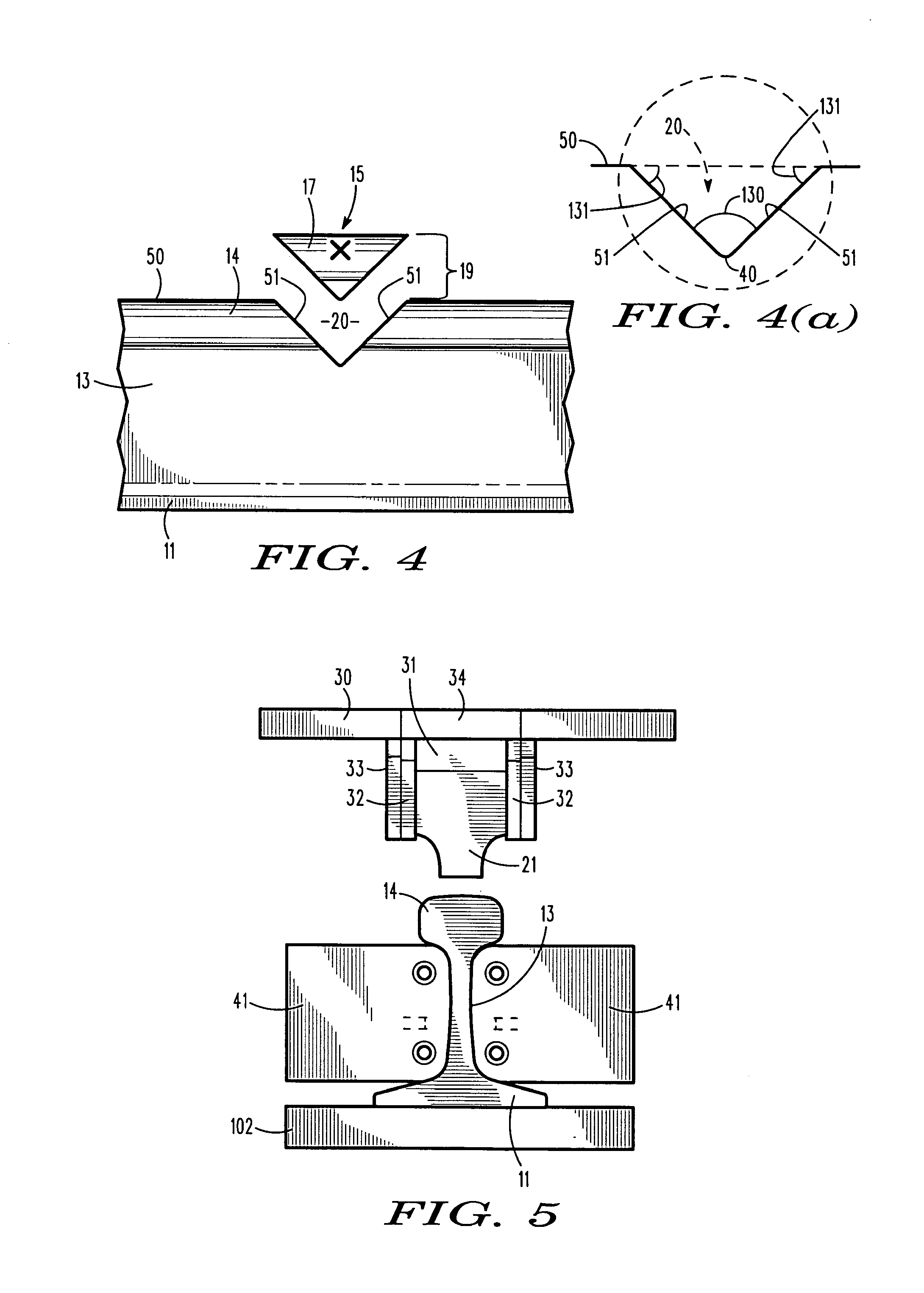

Forge welding method

InactiveUS20050236372A1MinimizationMinimize upsetArc welding apparatusWelding/soldering/cutting articlesEngineeringThermal expansion

The invention relates to a method for forge welding tubulars such that formation of upsets in the welding zone is minimized which involves shaping the tubular ends that are to be welded together into an inwardly sloping configuration such that when the tubular ends are heated during the forge welding process the heated tubular ends deform as a result of thermal expansion into a substantially longitudinally oriented cylindrical shape.

Owner:TUBEFUSE APPL

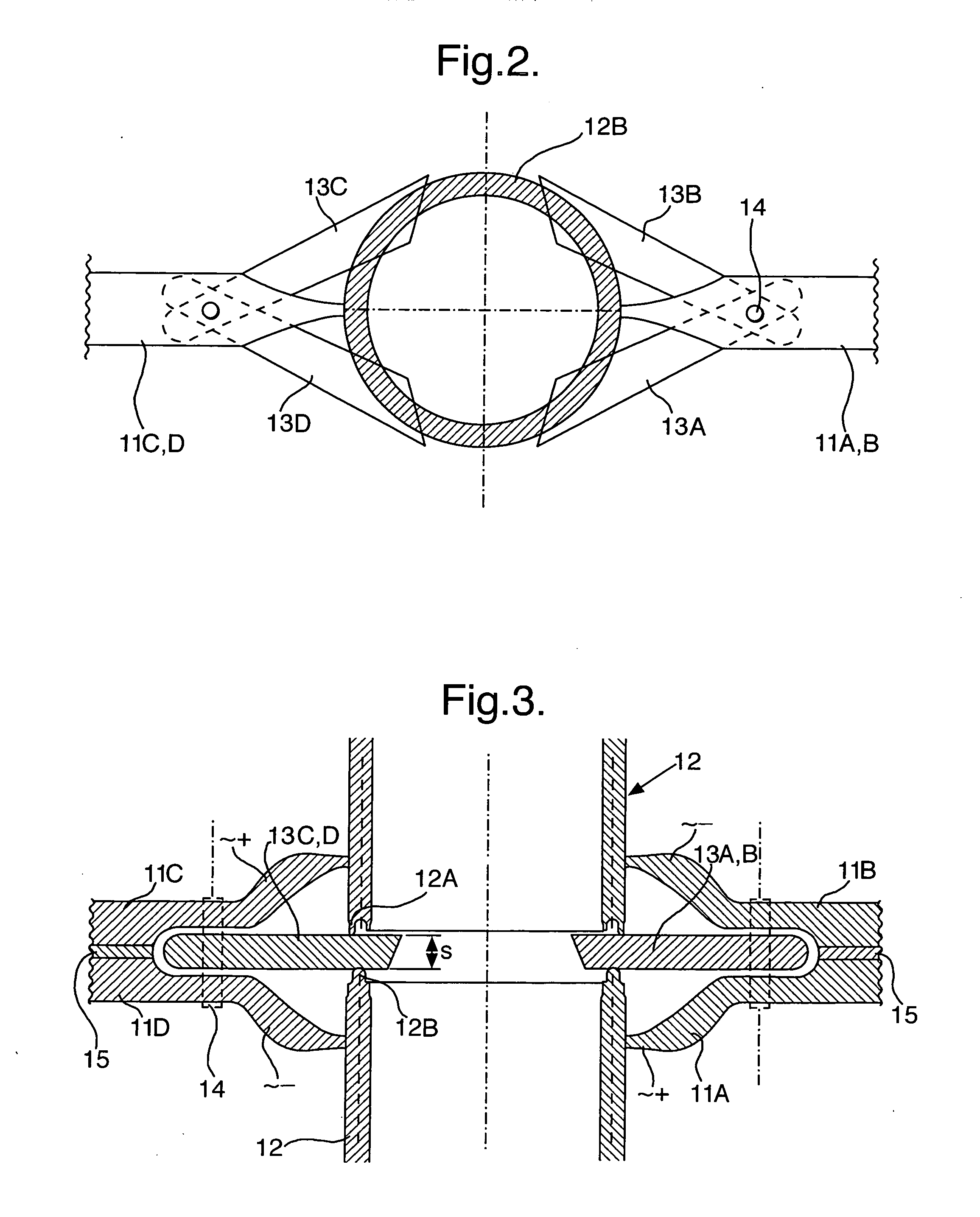

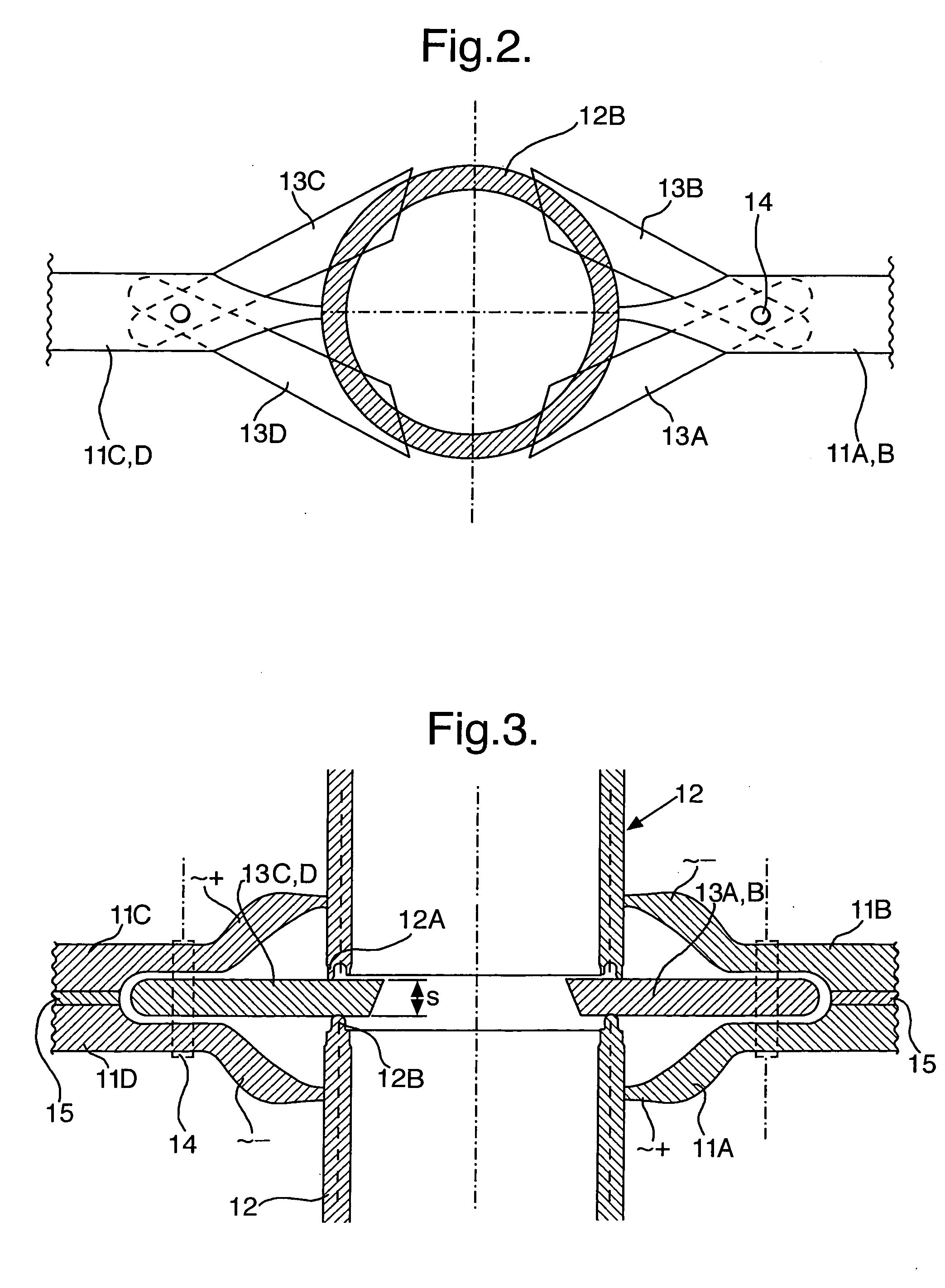

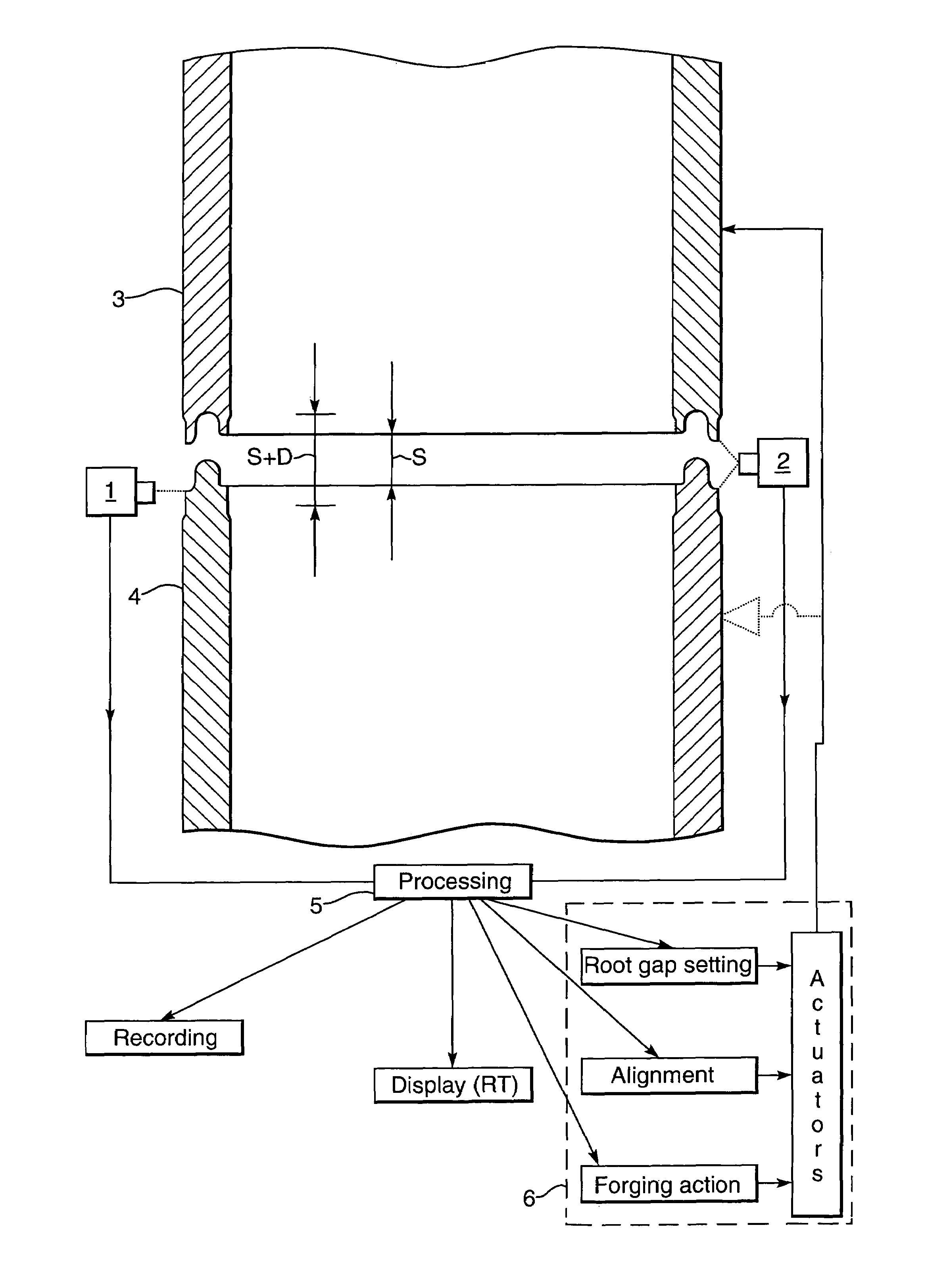

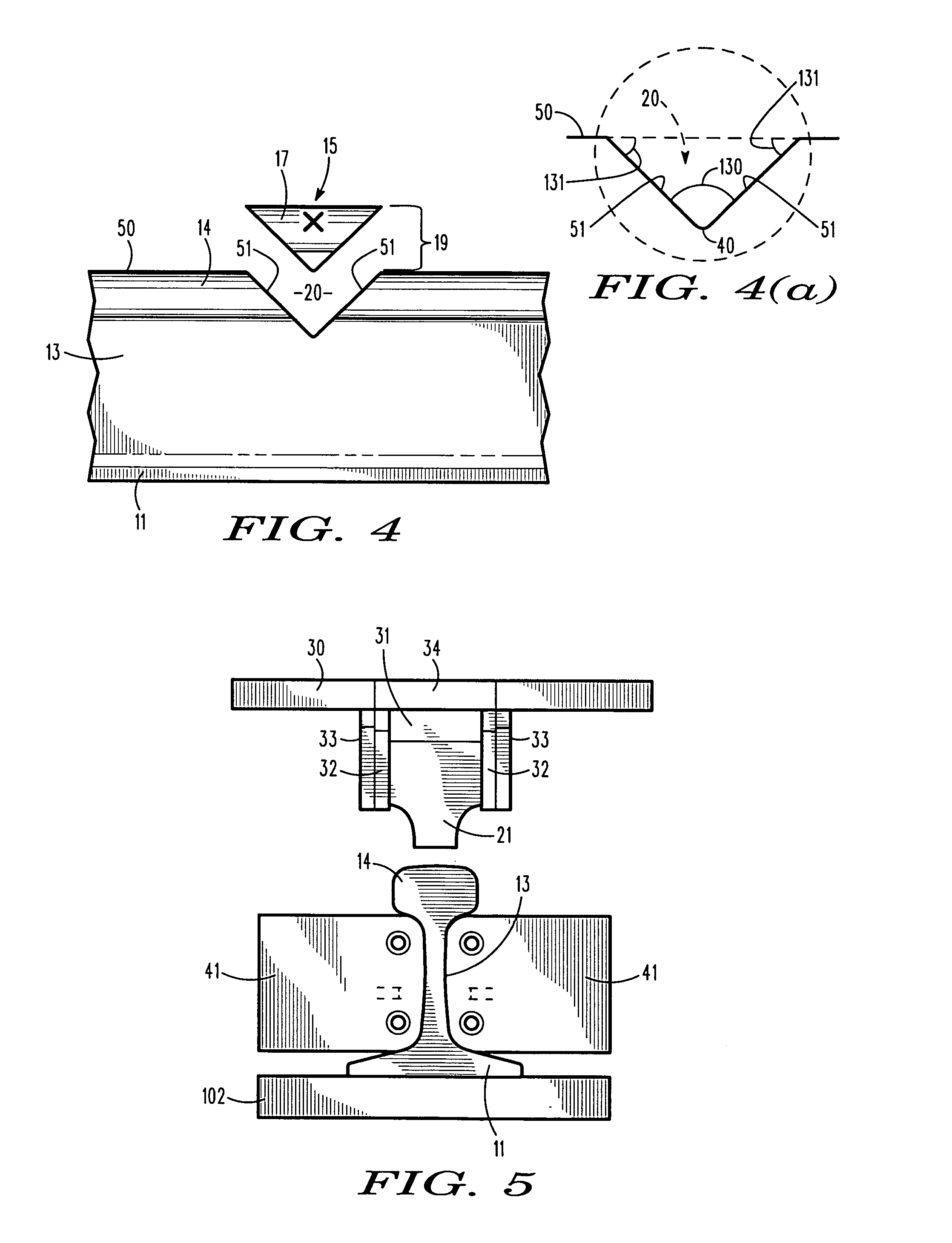

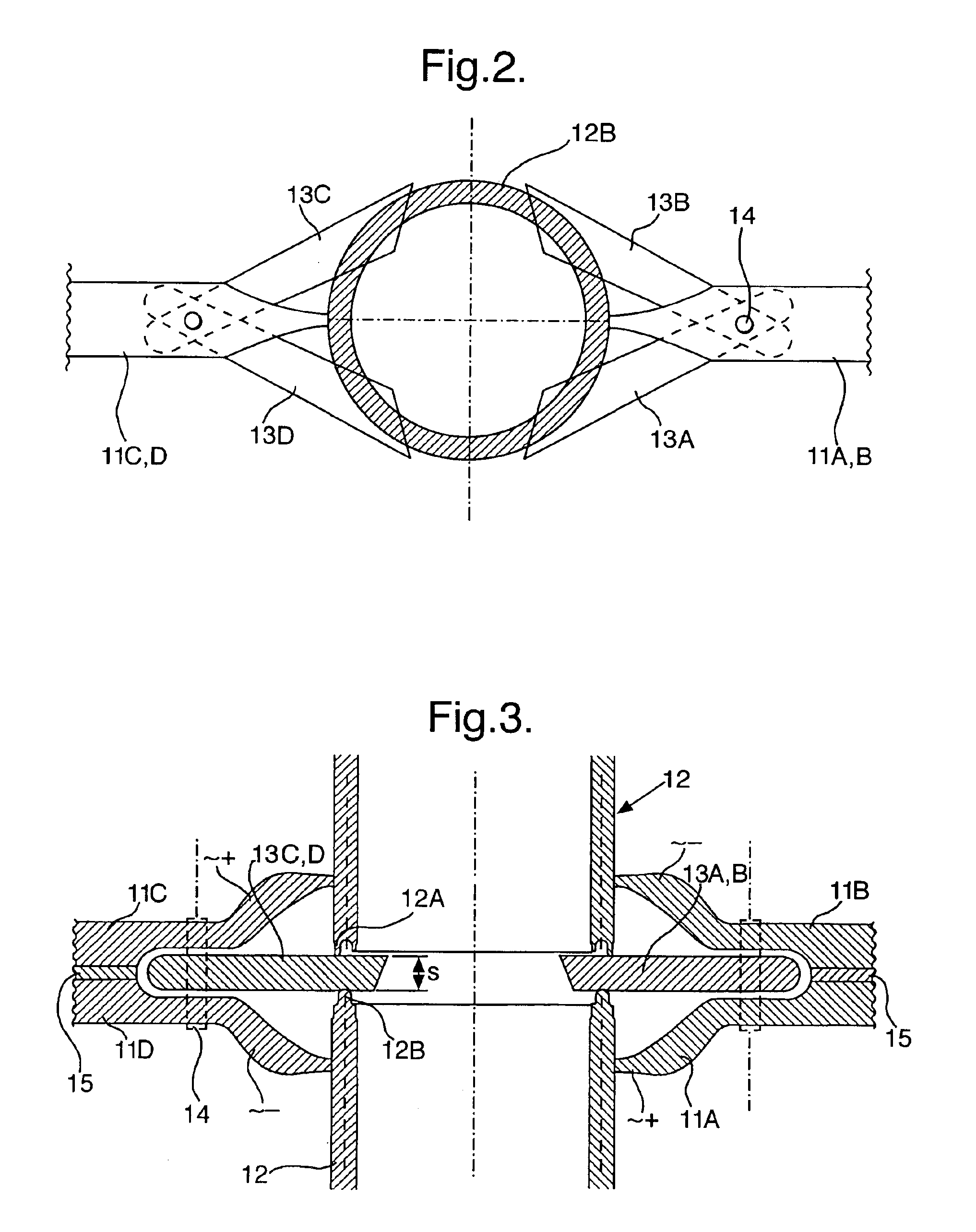

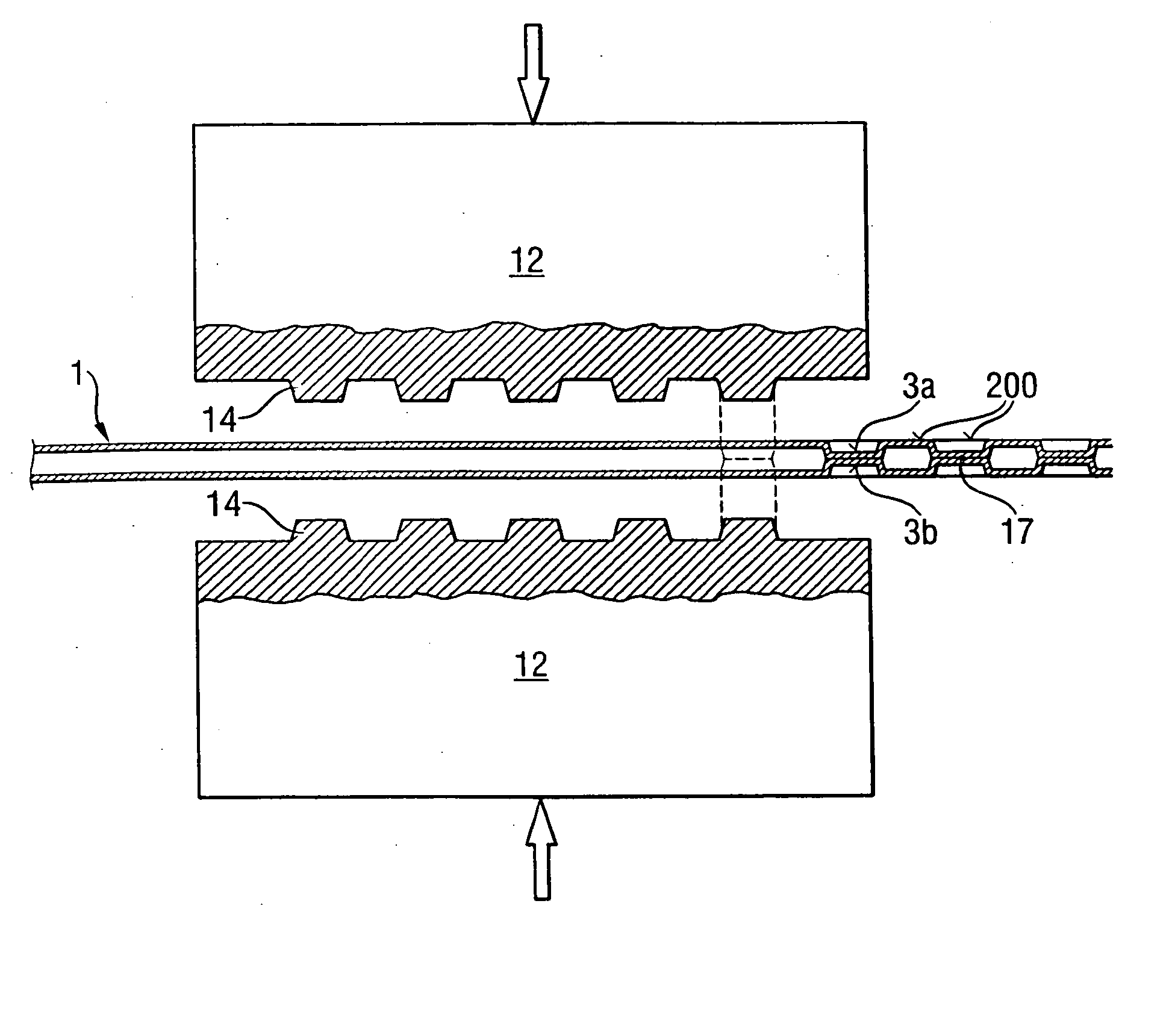

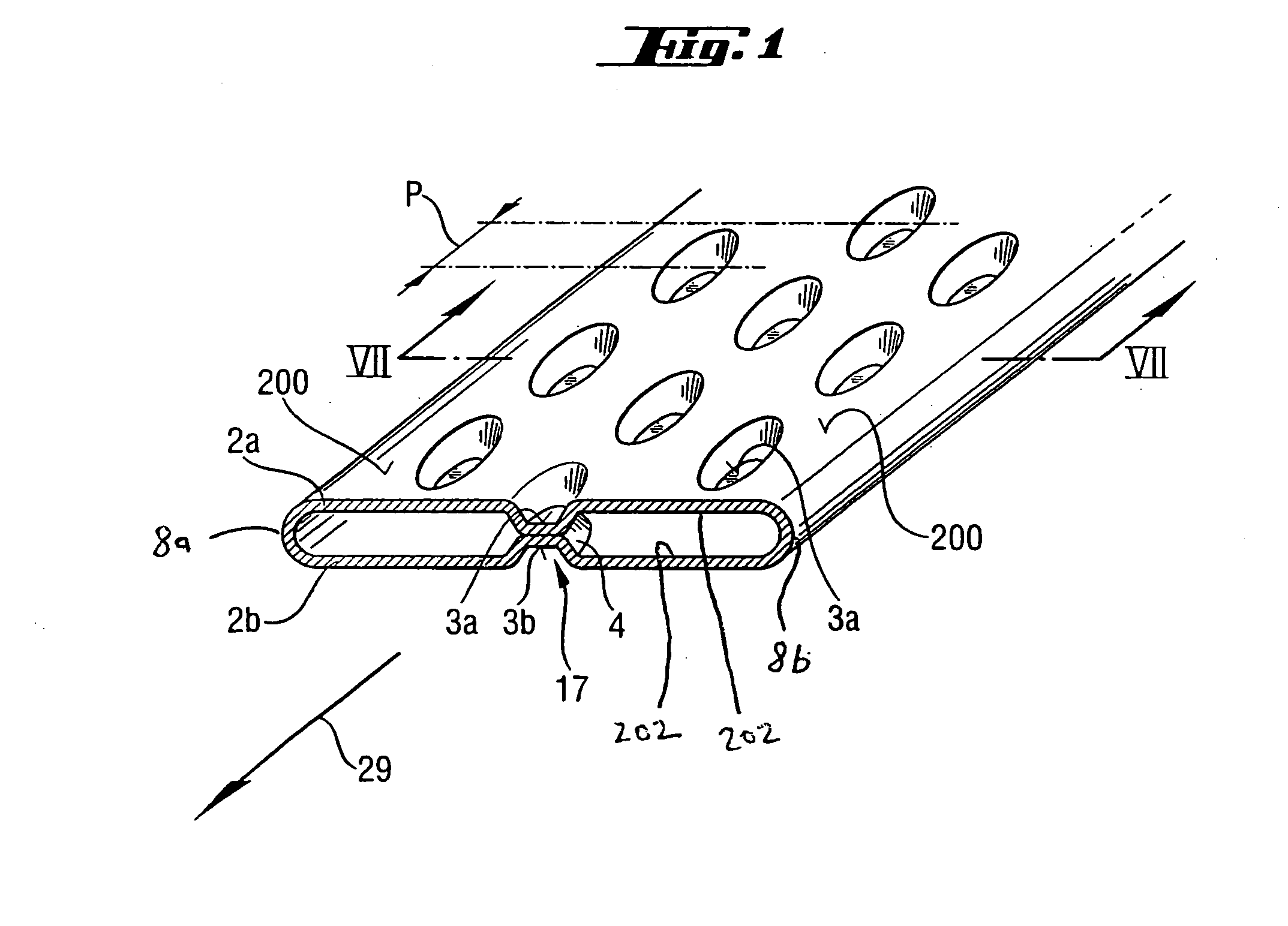

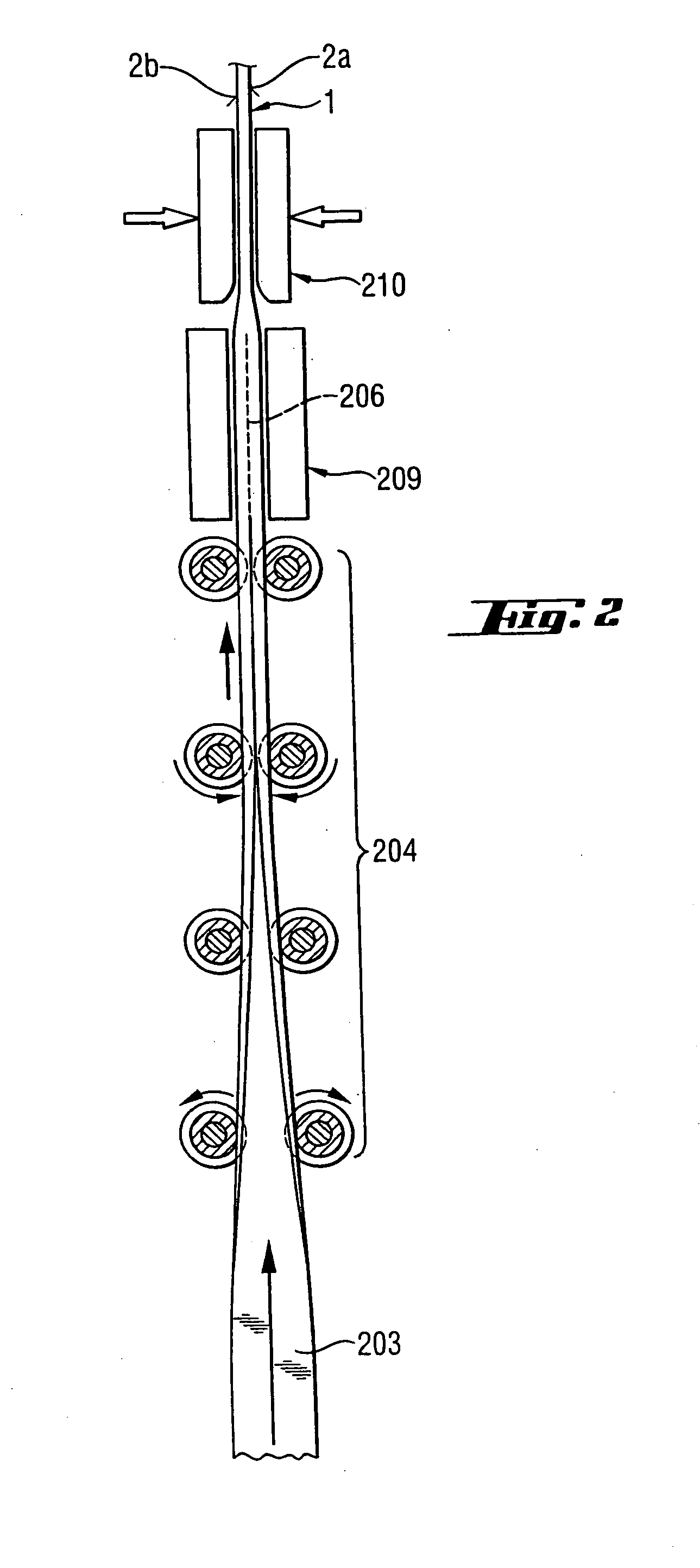

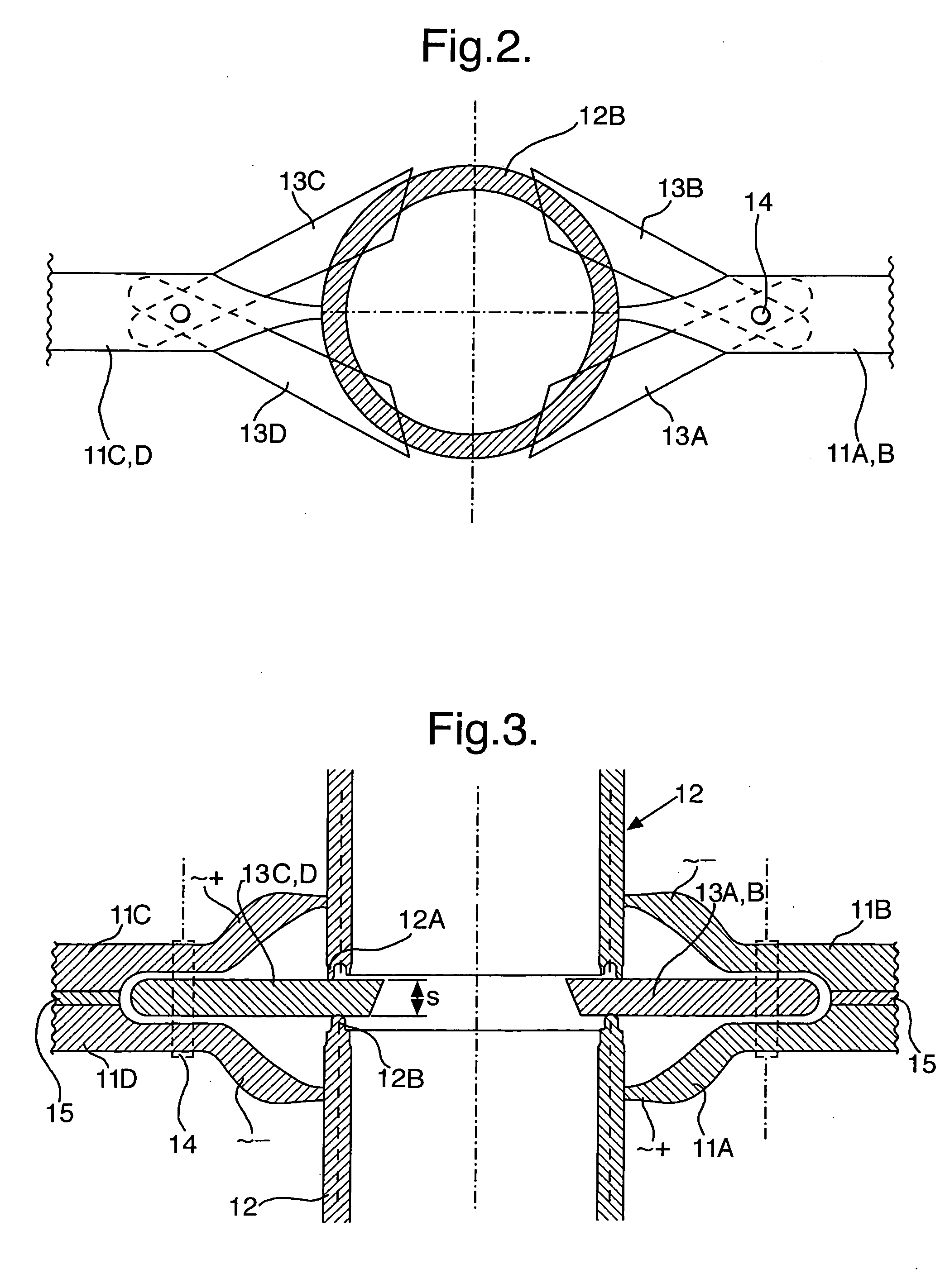

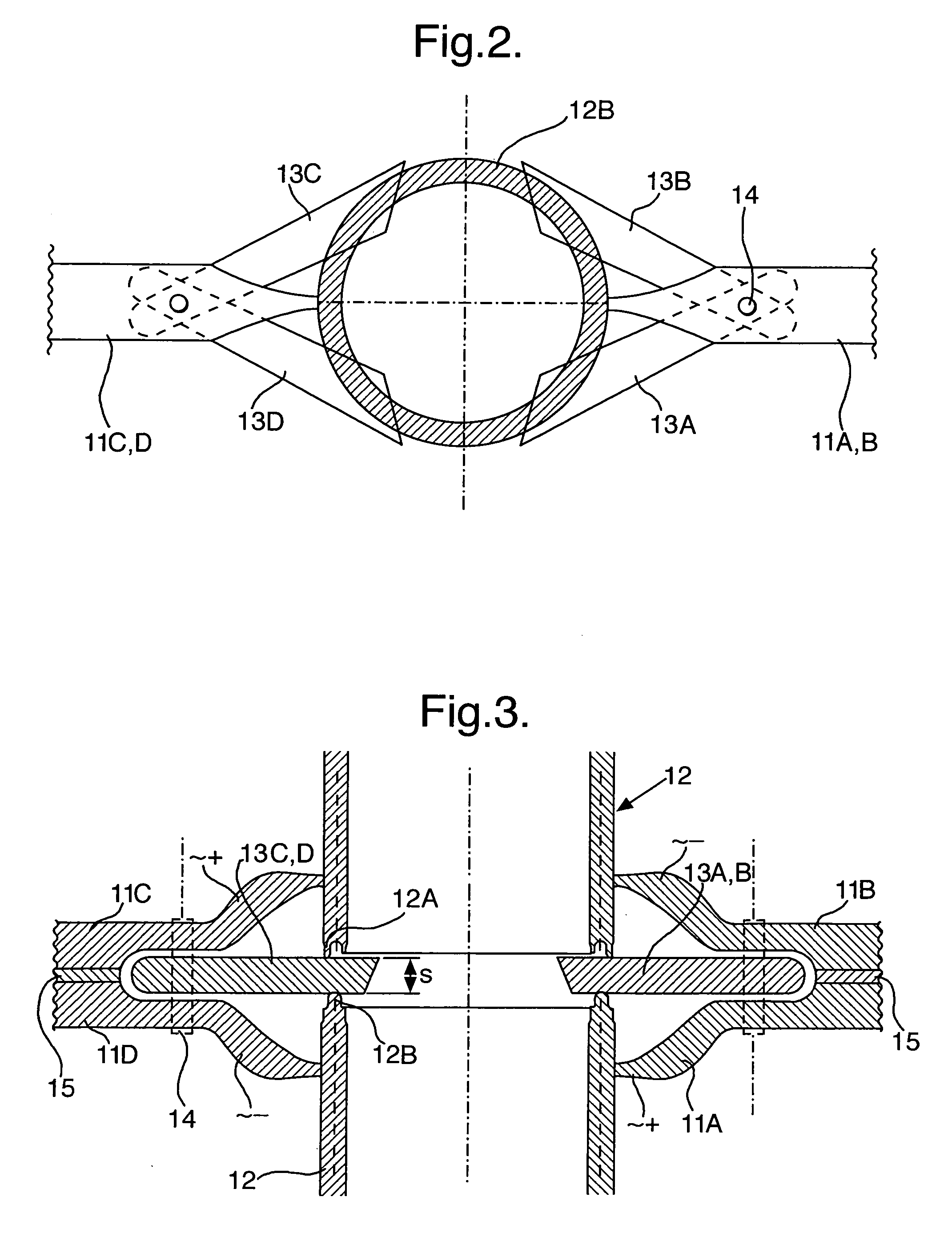

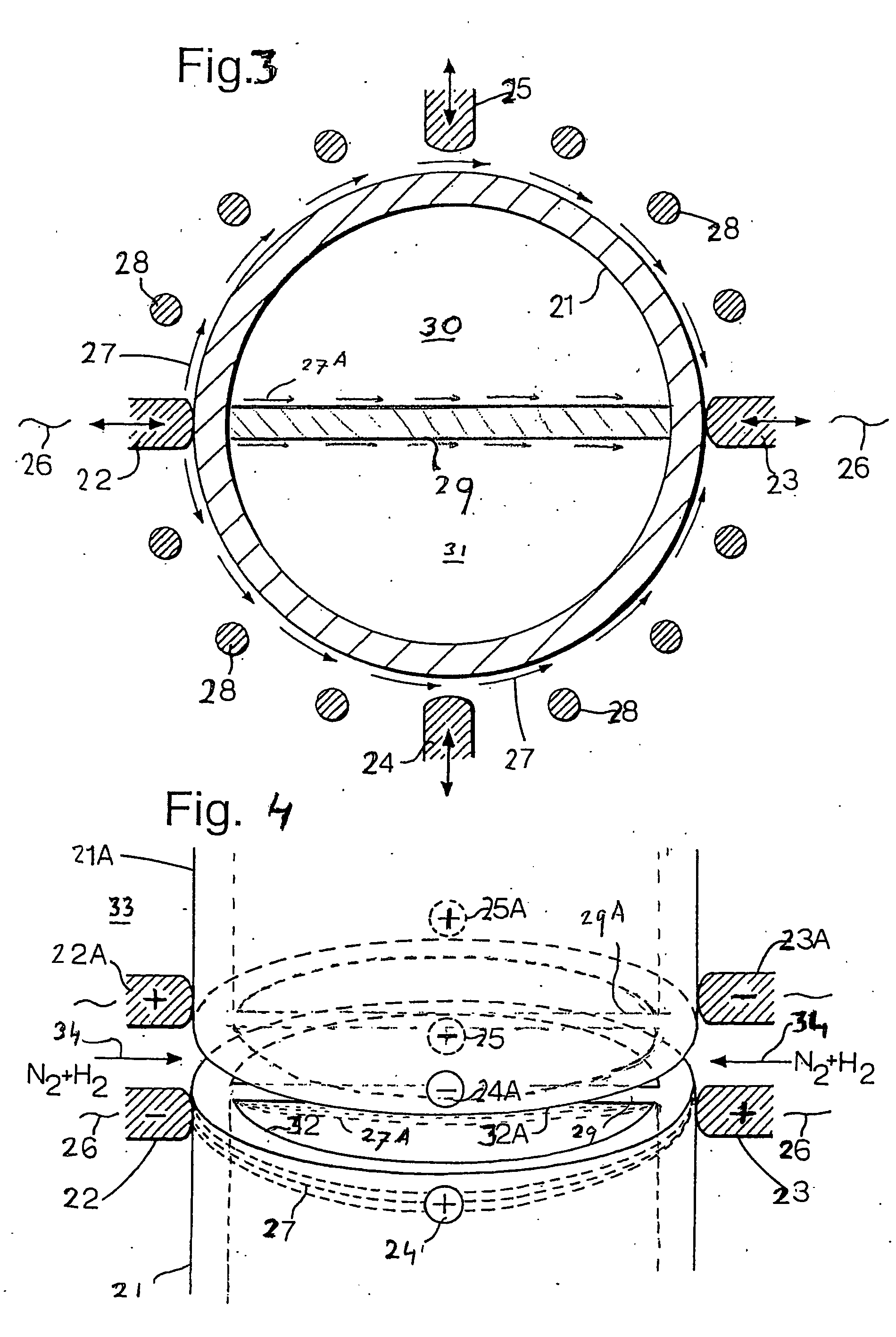

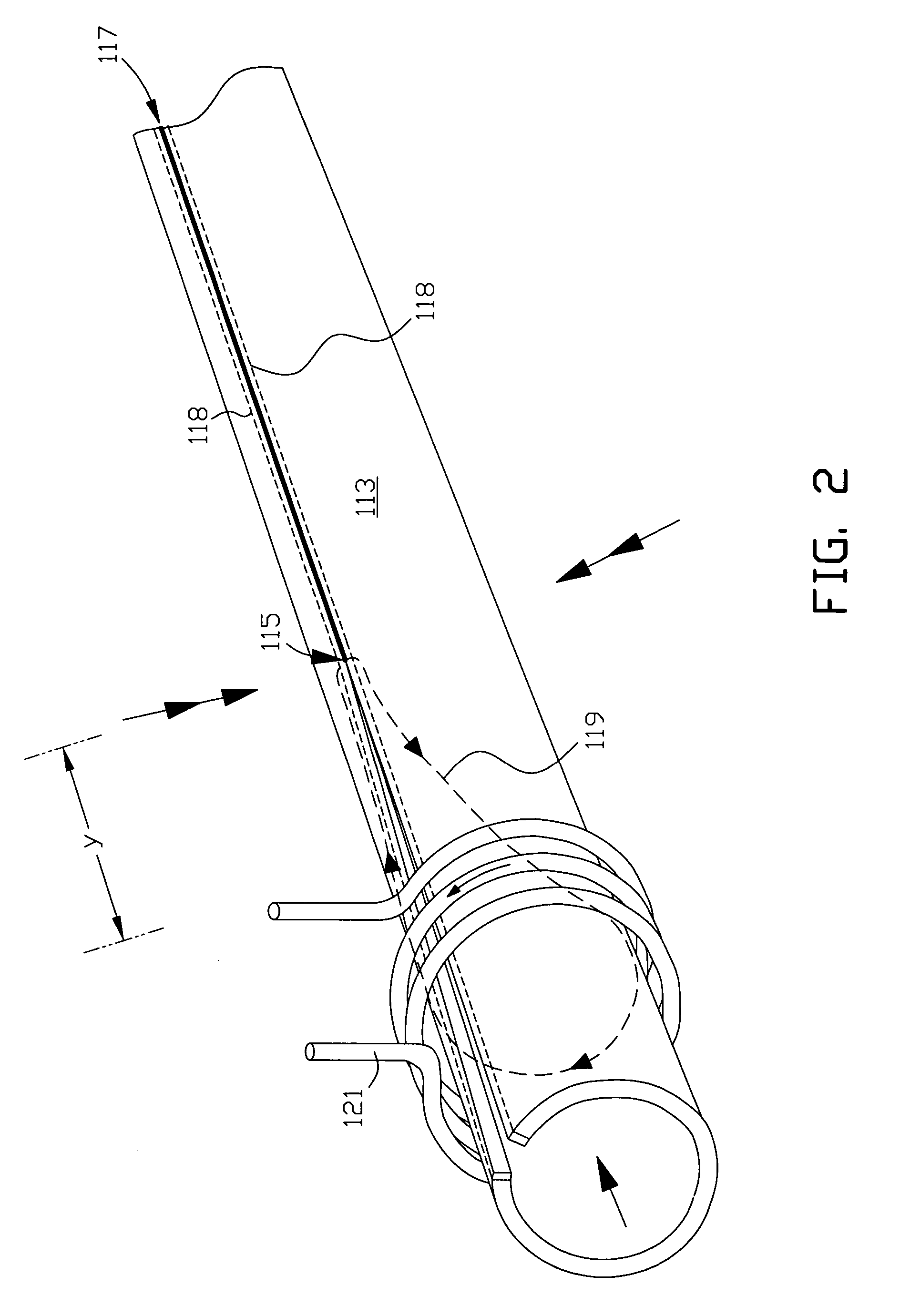

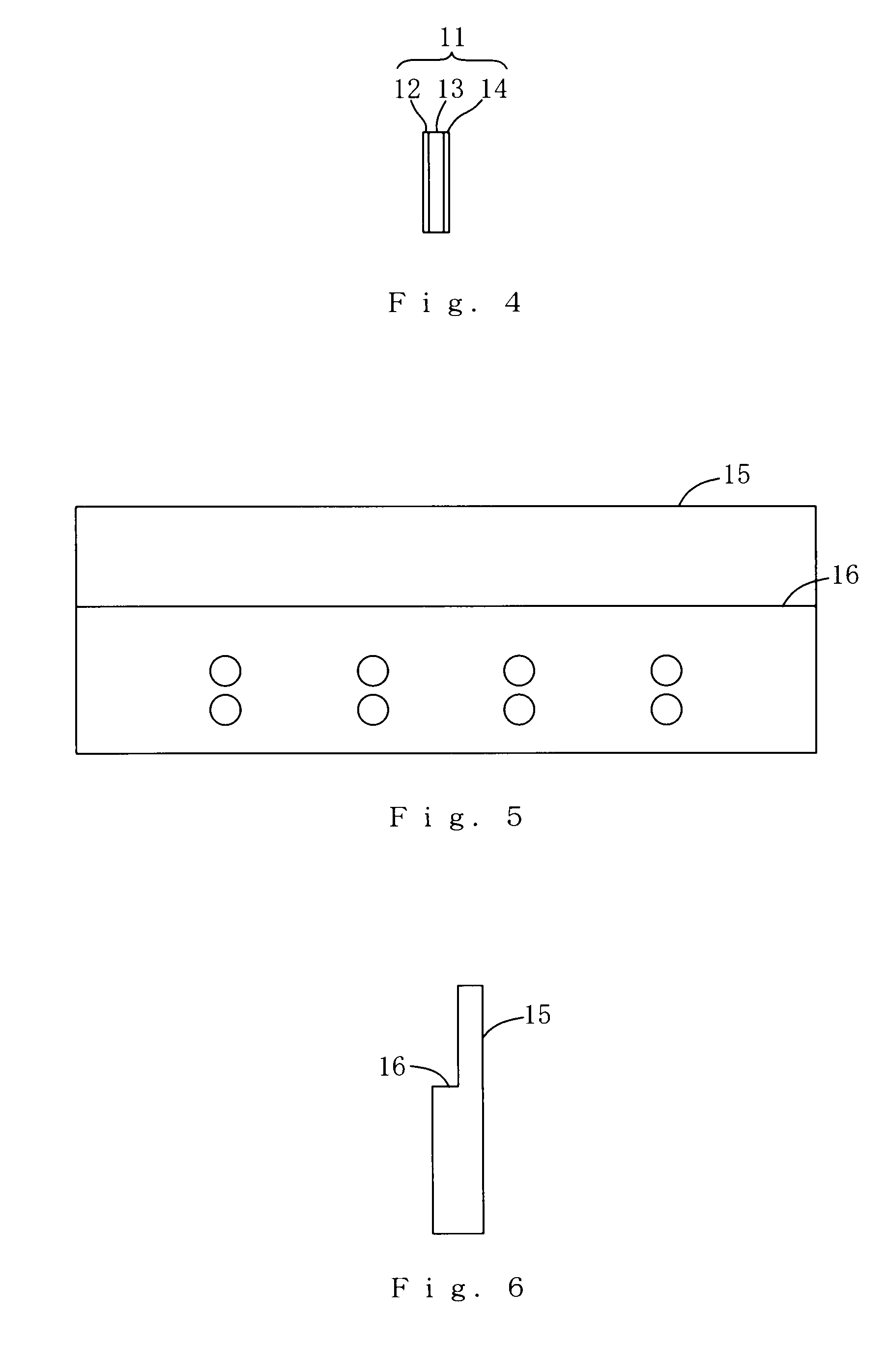

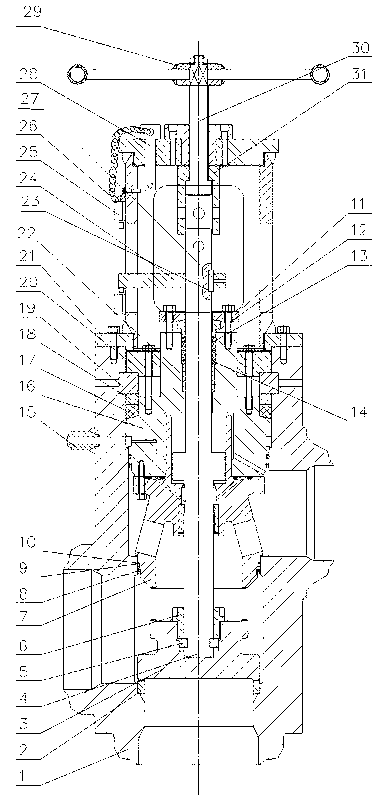

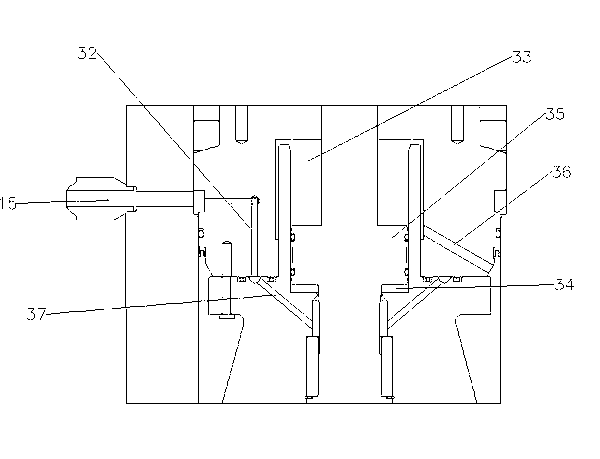

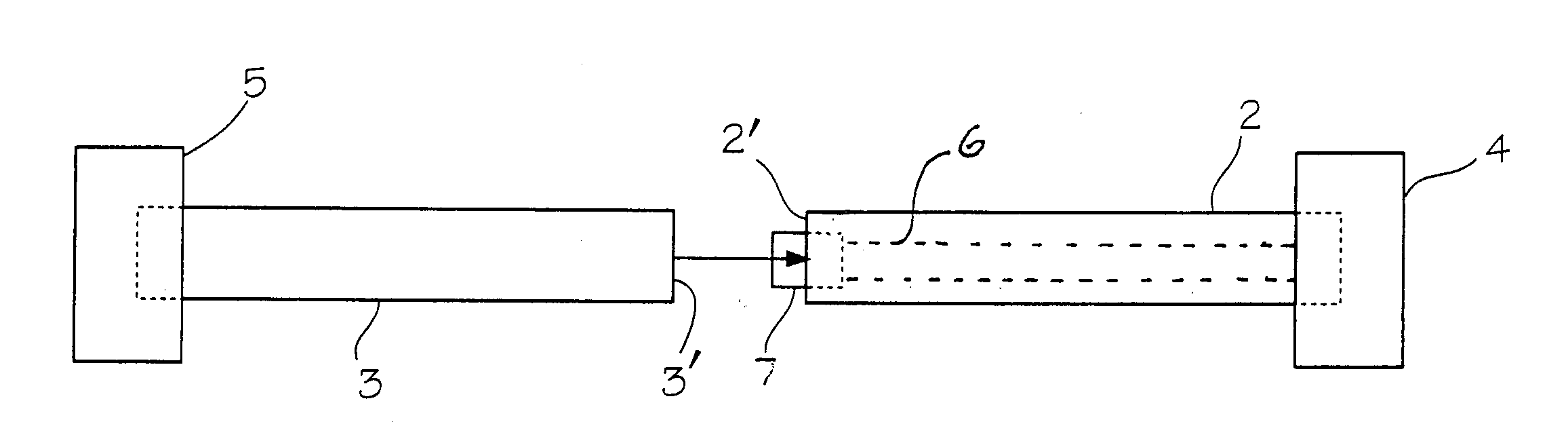

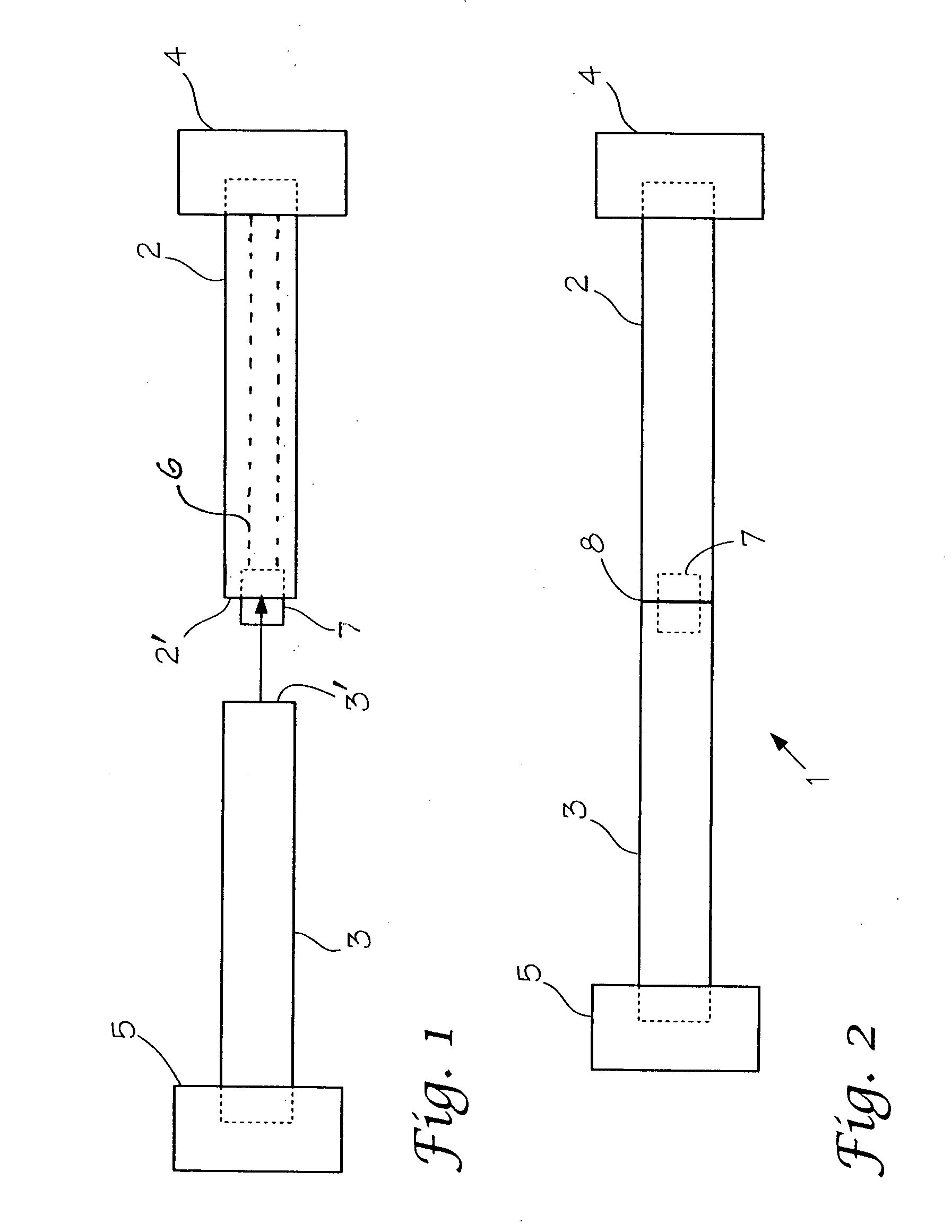

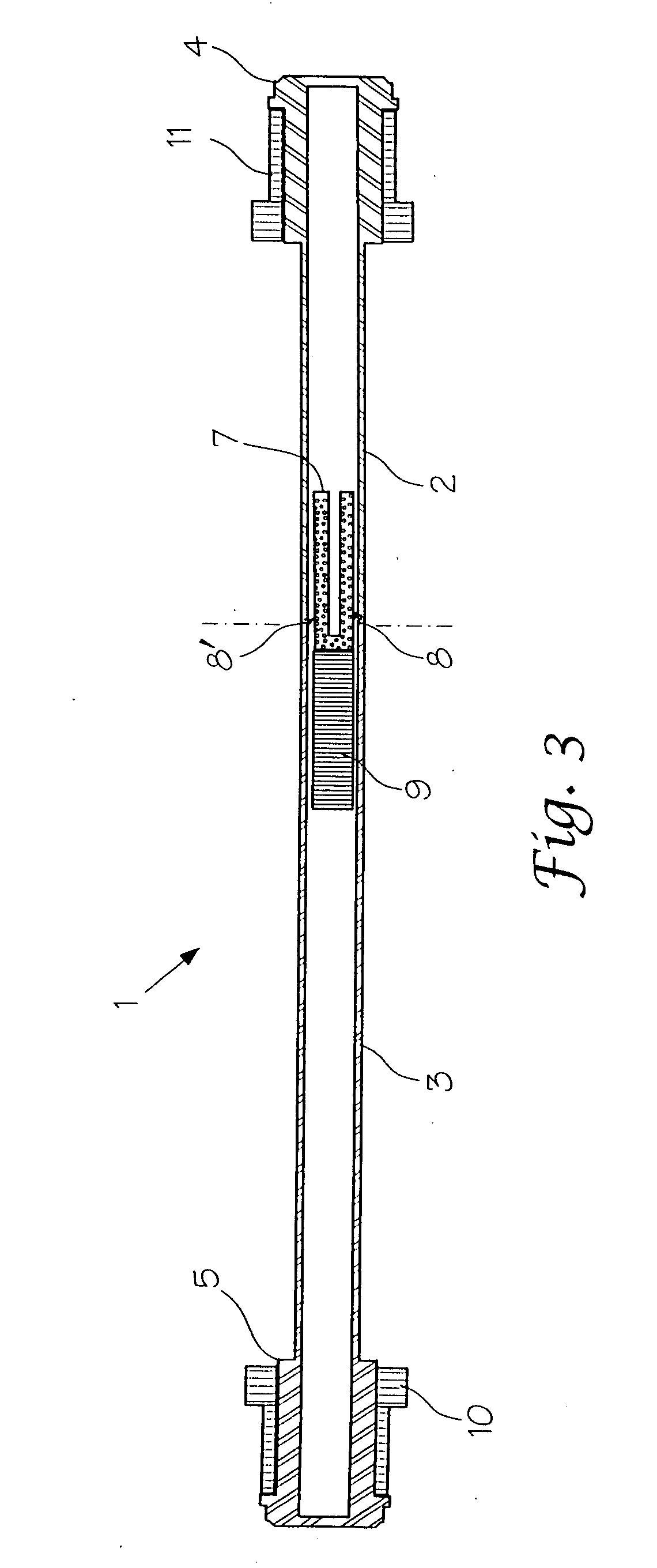

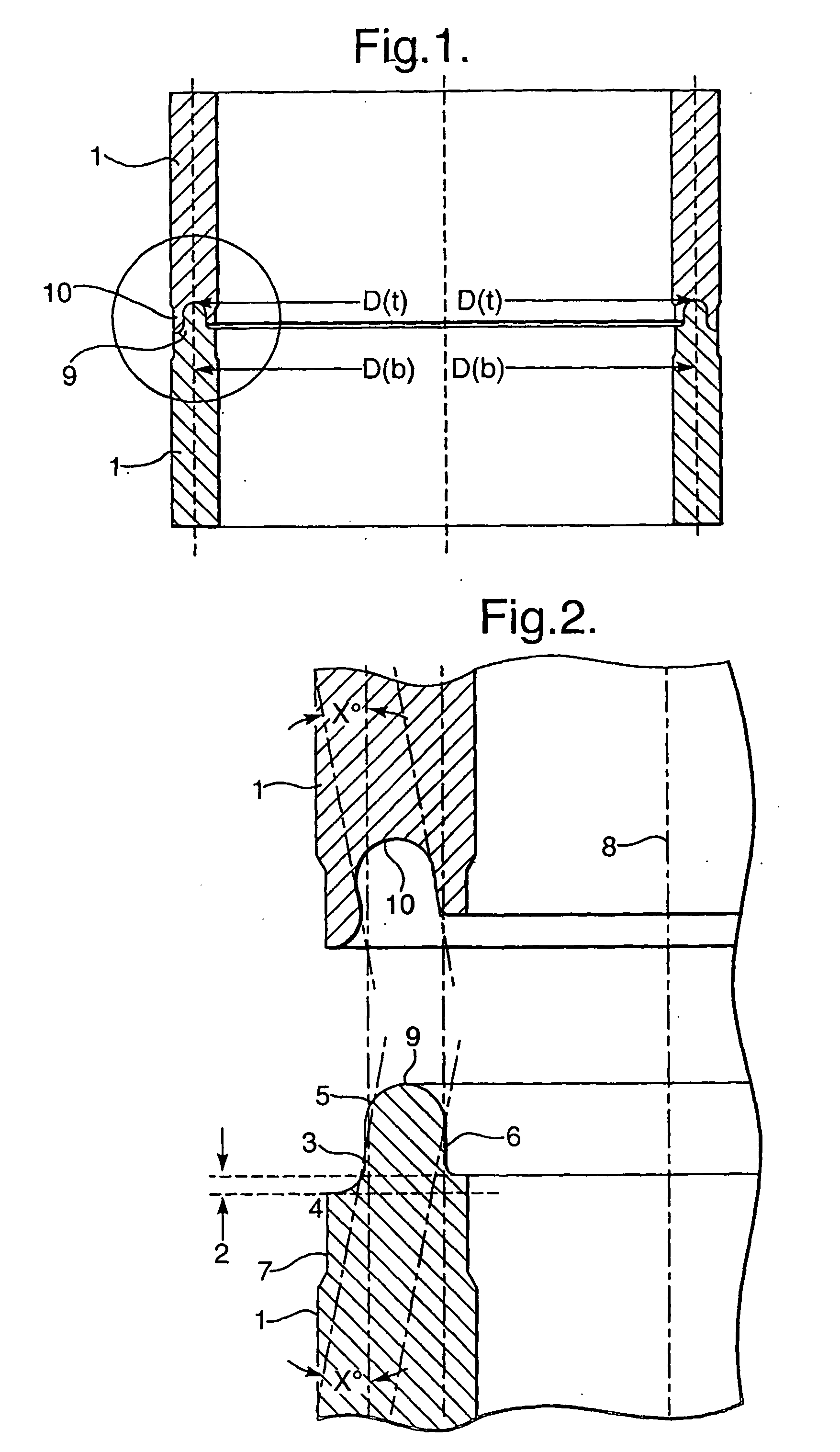

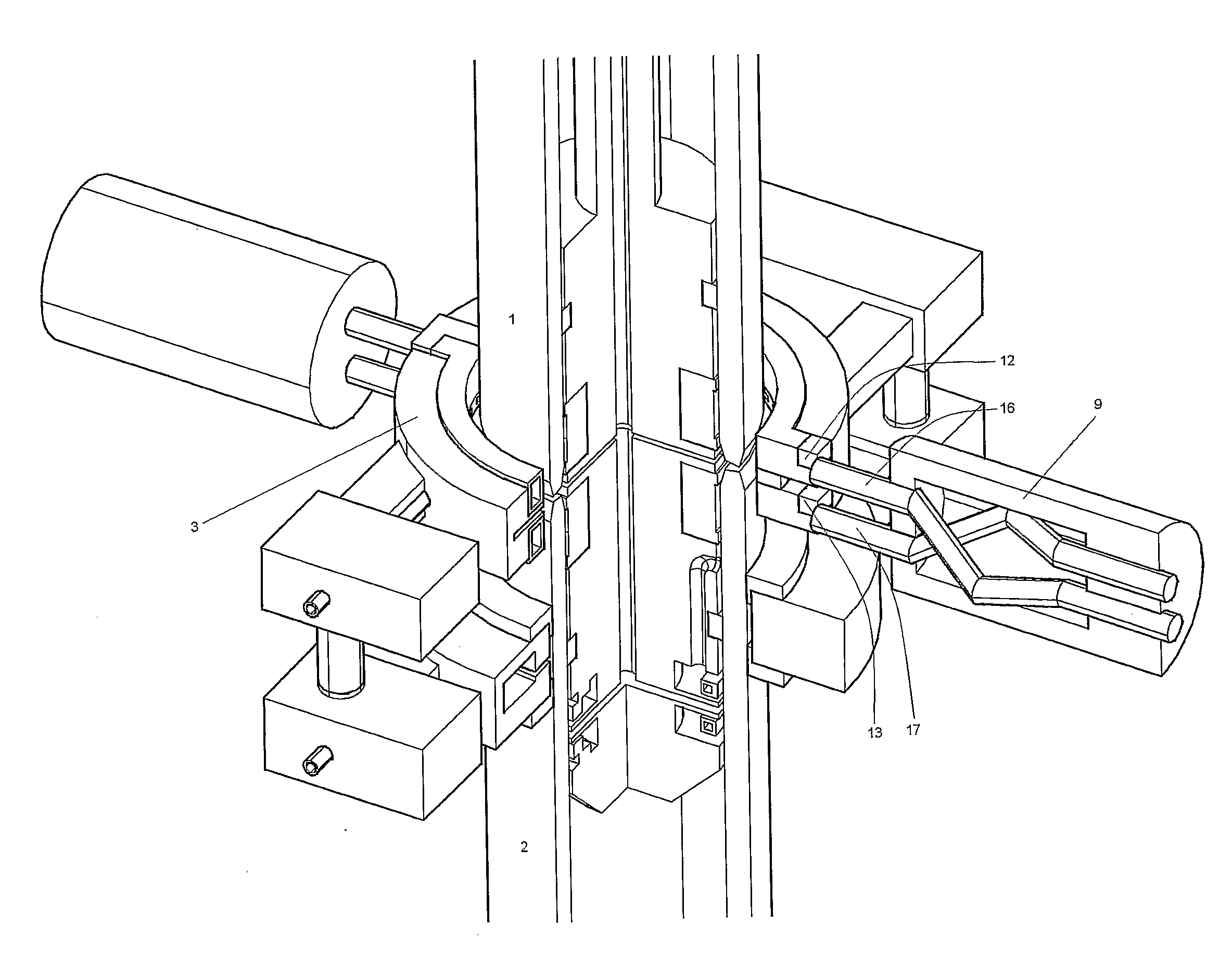

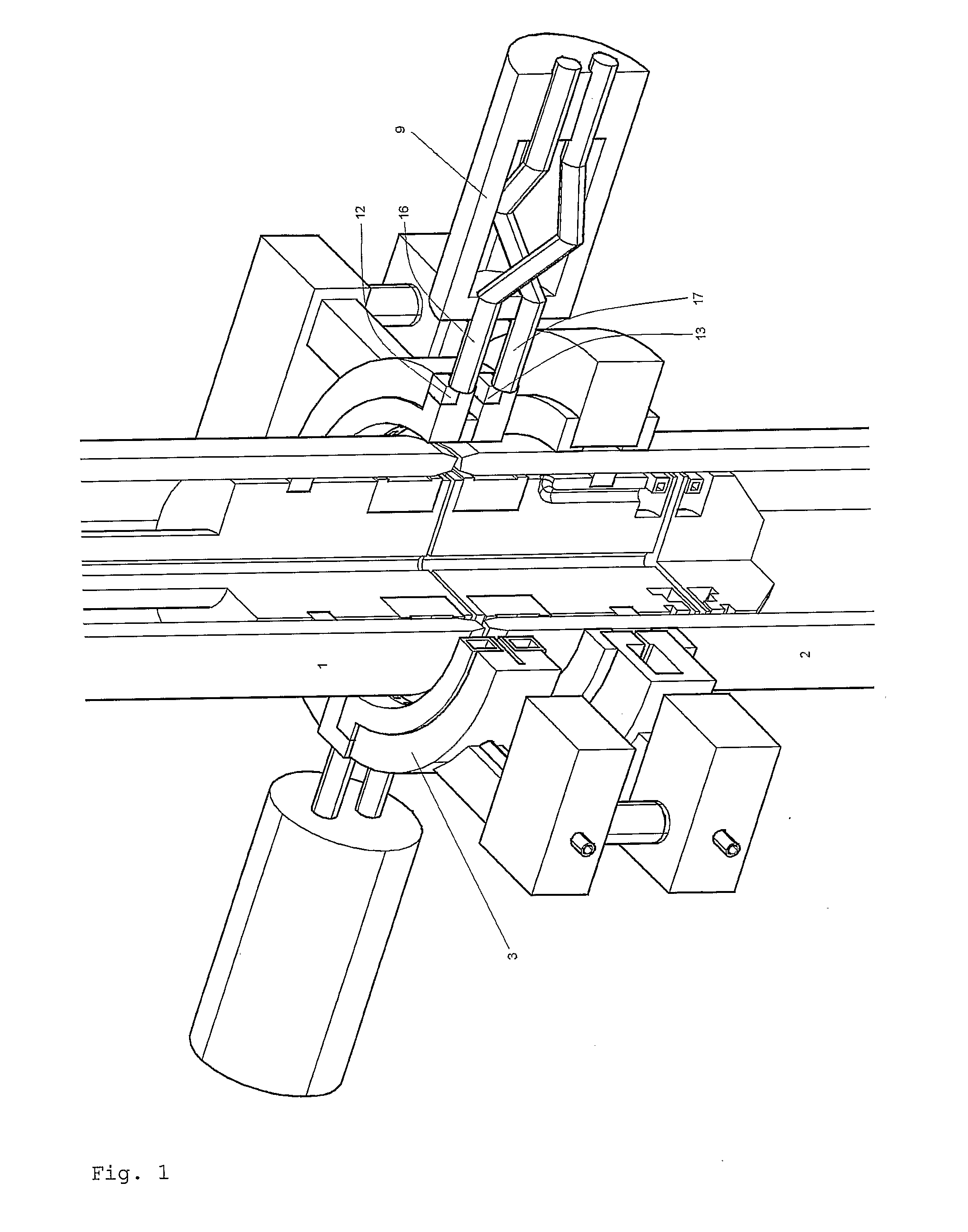

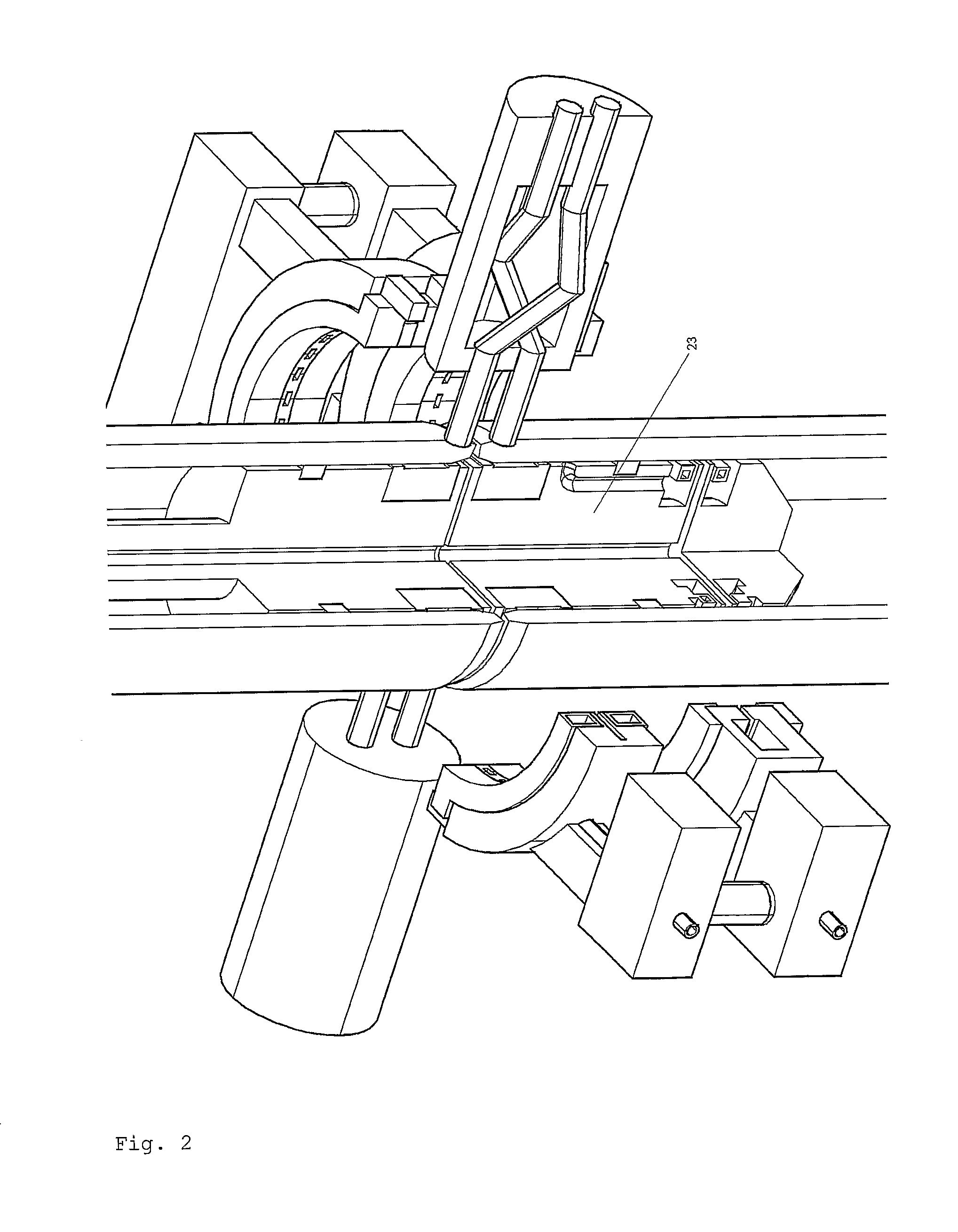

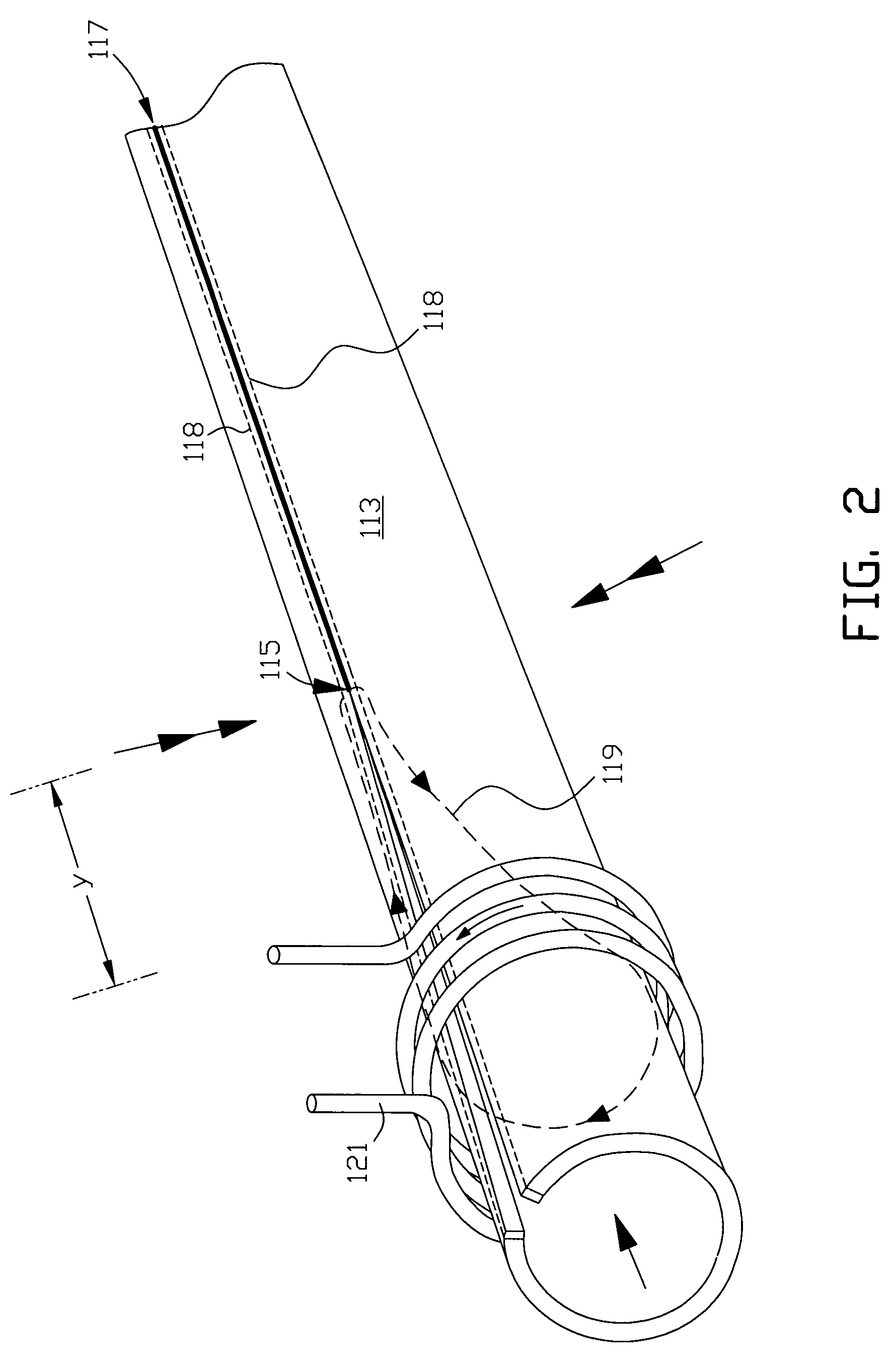

Apparatuses For and Methods of Forge Welding Elongated Articles with Electrodes and an Induction Coil

InactiveUS20100264131A1Easy temperature controlQuality improvementSoldering apparatusHigh frequency current welding apparatusEngineeringWeld seam

The present application relates to an apparatus for and a method of forge welding elongate articles (1, 2), such as tubes, together. In addition to electrode (12, 13) assemblies (9) for heating the article (1, 2) ends with high frequency resistive heating, the apparatus includes a coil (3) for induction heating the articles (1, 2) before or after welding, as well as means for cooling the welding seam.

Owner:AMR ENG

Method for Repairing Metallic Structure

InactiveUS20130284706A1Effective timeMore time of runningRailsRailway track constructionElectrical resistance and conductanceEngineering

Owner:HOLLAND CO

Method for interconnecting tubulars by forge welding

InactiveUS7199325B2Reduces unequal heatingReduce heatHigh frequency current welding apparatusResistance welding apparatusPower flowShielding gas

A method for interconnecting tubulars by forge welding involves arranging the tubular ends that are to be interconnected at a distance, up to a few millimeters from each other in a shield gas chamber, into which a reducing non-explosive flushing fluid mixture (e.g. N2+H2) is injected; heating each tubular end within the space by means of at least three electrodes that are pressed at circumferentially spaced intervals against the wall of each tubular, adjacent to the tubular end such that a high frequency electrical current is transmitted in a substantially circumferential direction through the tubular segments between the electrodes; and moving the thus uniformly heated tubular ends towards each other until a forge weld is formed between the heated tubular ends.

Owner:SHELL OIL CO

Forge welding technological method for large circle-shaped thin wall structure parts

InactiveCN100999052AHigh strengthExtended service lifeArc welding apparatusFurnace typesLarge sizeMachining

The present invention discloses a forge welding process of large-size square-ring-shaped thin-walled structure component. Said forge welding process includes the following steps: (1), forging raw material to obtain blank; (2), die forging-forming; (3) heat bending-forming by means of die; (4) making group welding, before welding making preheating treatment, adopting welding mould and adopting mixed gas shielded welding, after welding making heat-insulating treatment; and (5) making thermal refining treatment.

Owner:CRRC SIFANG CO LTD

System and method of computing the operating parameters of a forge welding machine

ActiveUS7683288B2High frequency current welding apparatusWelding/soldering/cutting articlesMulti materialHeat-affected zone

A system and method for computing the parameters of a forge welding machine for the forge welding of one or more materials is provided. A computer program executes a self-tuning routine to compute the operating frequency and operating power setting for the forge welding machine in response to an inputted width of the heat affected zone and an inputted weld temperature.

Owner:THERMATOOL

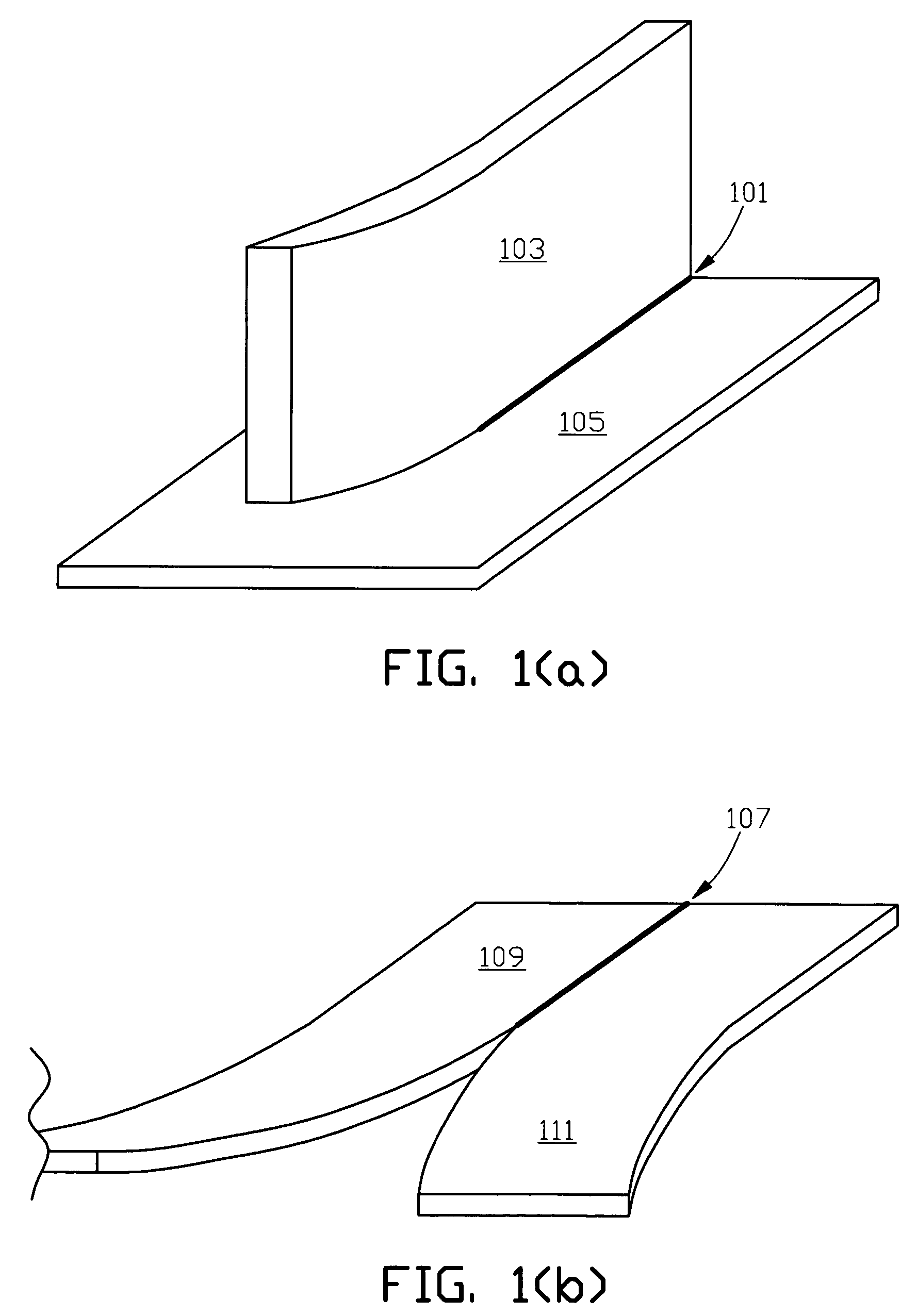

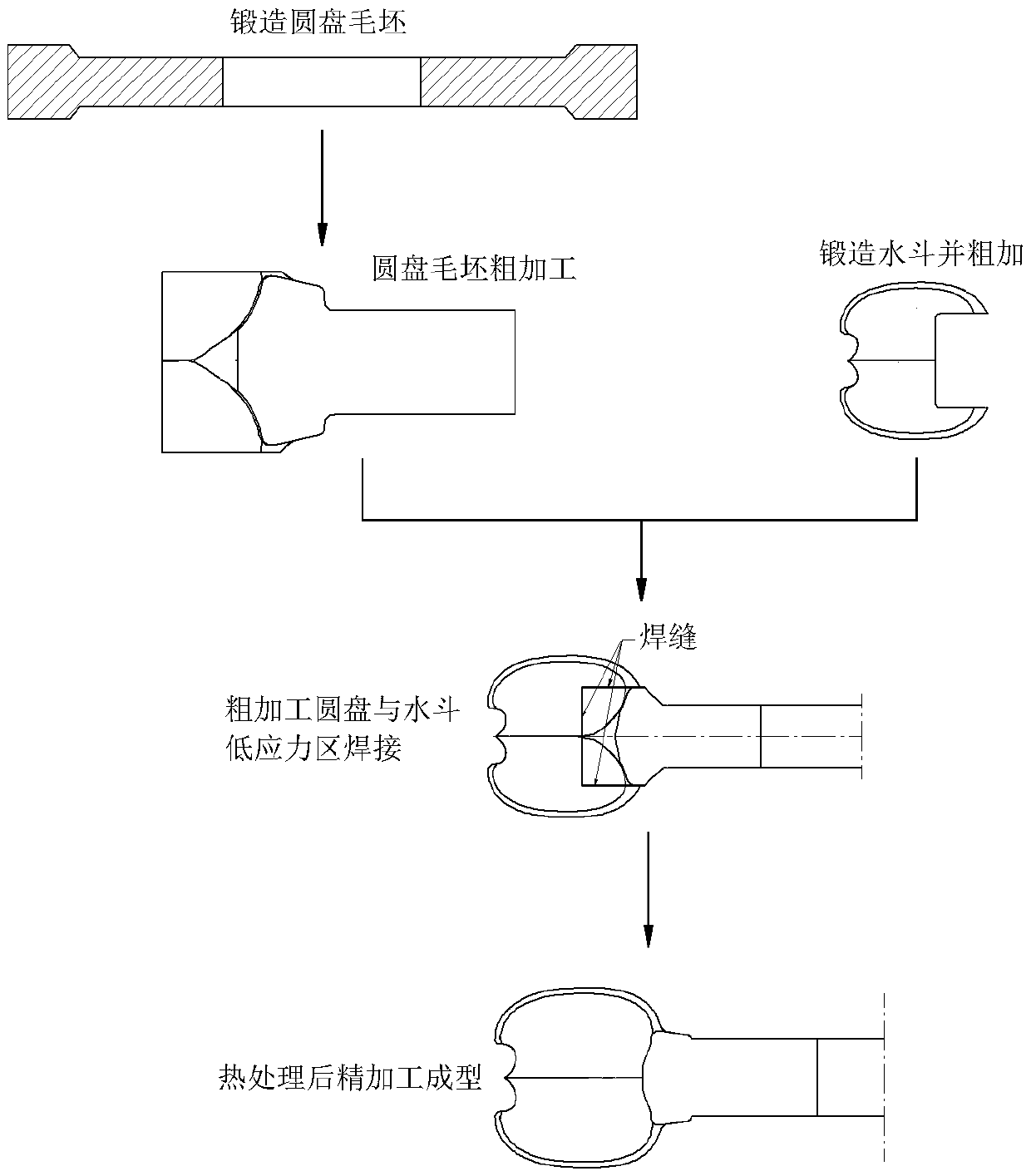

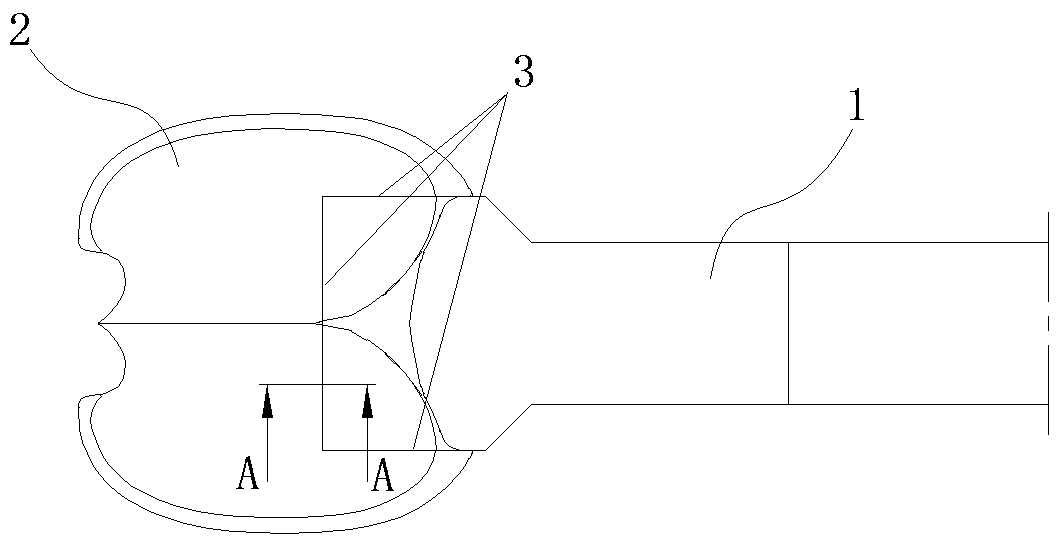

Impact type water bucket fine welding sectioning method and structure

InactiveCN110449832AReduce the amount of weldingGuaranteed welding economyFinal product manufactureHydro energy generationStructure of the EarthForge welding

The invention discloses an impact type water bucket fine welding sectioning method and structure. The method comprises the following steps that a, a region with relatively low stress is found betweena water bucket and a disc, and a forged welding boundary is drawn in a low stress area; b. a disc is produced through forging and carrying out acceptance inspection; c, the machining allowance of thedisc is reserved according to the deformation amount possibly generated by surfacing and heat treatment, and rough machining of the forging disc is completed; d, each water bucket forging blank is manufactured, the machining allowance of the water bucket is reserved, and rough machining work of the independent water bucket is completed; e, the rough machining water bucket is welded on the rough machining disc; and f, stress removal heat treatment is performed after finish welding, and finish machining is performed after the flaw detection is qualified. The invention aims to provide the impacttype water bucket fine welding sectioning method and structure which can reduce forging difficulty and meet the manufacturing capability requirements of existing forging equipment.

Owner:浙江富春江水电设备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com