Vibrating casting and forging composite forming method for aluminum alloy forgings

A composite forming and aluminum alloy technology is applied in the field of vibration casting and forging composite forming of aluminum alloy forgings, which can solve the problems of poor compaction effect and poor forging penetration of casting preforms, and achieves low equipment investment and high material utilization rate. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: including alloy smelting, squeeze casting and vibration die forging steps, is characterized in that:

[0027] (1) Alloy melting:

[0028] Use an aluminum alloy melting furnace to heat the 6061 aluminum alloy raw material to its liquidus temperature above 650°C and 80°C, that is, 730°C, and melt and smelt it to form an aluminum alloy melt;

[0029] (2) Squeeze casting:

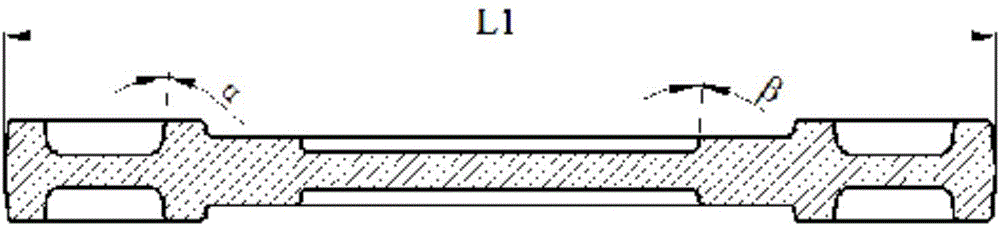

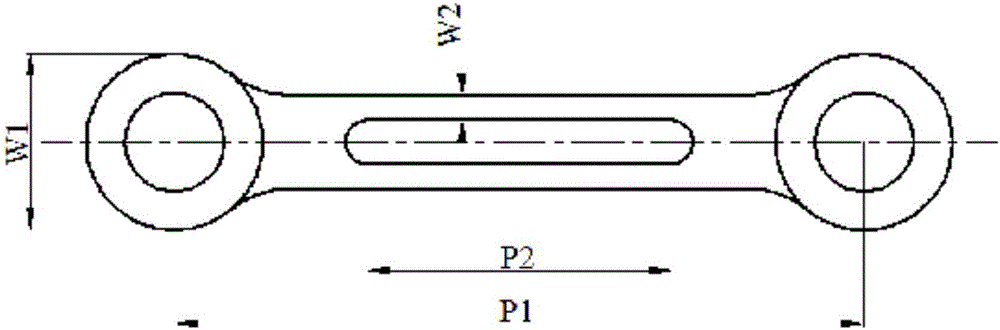

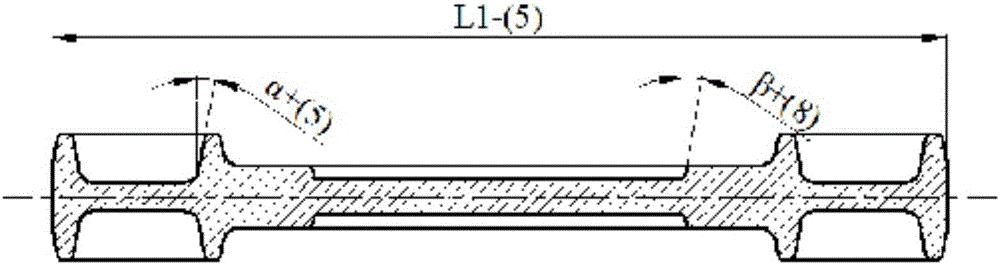

[0030] When the temperature of the aluminum alloy melt drops to above the liquidus temperature of 650°C and 60°C, that is, 710°C, it is poured into the cavity of a metal mold squeeze casting mold installed on a 1000kN squeeze casting press, and the aluminum alloy melt follows After the mold is cooled for 10s, the die punch is driven by the extrusion casting press slider to apply a specific pressure of 200MPa to the aluminum alloy melt in solidification and cooling, and keep it for 10s. After cooling, the extrusion casting preform of the aluminum alloy connecting rod is obtained. As shown ...

Embodiment 2

[0036] Embodiment 2: including alloy smelting, squeeze casting and vibration die forging steps, is characterized in that:

[0037] (1) Alloy melting:

[0038] Use an aluminum alloy melting furnace to heat the 6061 aluminum alloy raw material to its liquidus temperature above 650°C and 80°C, that is, 730°C, and melt and smelt it to form an aluminum alloy melt;

[0039] (2) Squeeze casting:

[0040] When the temperature of the aluminum alloy melt drops to above the liquidus temperature of 650°C and 60°C, that is, 710°C, it is poured into the cavity of a metal mold squeeze casting mold installed on a 1000kN squeeze casting press, and the aluminum alloy melt follows After the mold is cooled for 10s, the die punch is driven by the slide of the extrusion casting press to apply a specific pressure of 200MPa to the aluminum alloy melt in solidification and cooling, and keep it for 10s. After cooling, the extrusion casting preform of the aluminum alloy control arm is obtained. pieces; ...

Embodiment 3

[0045] Embodiment 3: including alloy smelting, squeeze casting and vibration die forging steps, is characterized in that:

[0046] (1) Alloy melting:

[0047] Use an aluminum alloy melting furnace to heat the A390 aluminum alloy raw material to its liquidus temperature above 650°C and 120°C, that is, 770°C, and melt and smelt it to form an aluminum alloy melt;

[0048] (2) Squeeze casting:

[0049] When the temperature of the aluminum alloy melt drops below the liquidus temperature of 650°C to 100°C, that is, 750°C, it is poured into the cavity of a metal mold squeeze casting mold installed on a 1000kN squeeze casting press, and the aluminum alloy melt follows After the mold is cooled for 5s, the die punch is driven by the slide of the extrusion casting press to apply a specific pressure of 100MPa to the aluminum alloy melt in solidification and cooling, and keep it for 20s. After cooling, the aluminum alloy swash plate extrusion casting preform is obtained. pieces;

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com