Sand-glass-shaped metal graded construction forming method

An hourglass-shaped, metal technology, applied in the field of metal material manufacturing, can solve the problems of large forgings, interface breaking vacuum, scrapping, etc., to achieve the effects of low-cost manufacturing, fast solidification speed, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

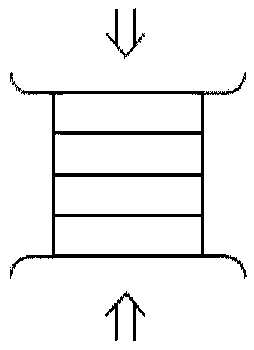

[0056] The target product of this embodiment is a 316 stainless steel ring. Firstly, the continuous casting method is adopted, and the continuous casting slab with a width of 1000mm and a thickness of 300mm is poured, and its steel type is 316H. Then cut out the continuous casting slab element with a length of 1000mm, process and clean it, seal and weld it into a preform in a vacuum chamber. After the preform is forged and welded and further forged, a 10t-level blank element is obtained. After surface processing, cleaning, stacking, encapsulation, forging and welding, and further forging, 4 pieces of 10t-level rough base units were used to obtain 2 pieces of 20t-level rough base units. After surface processing, cleaning, stacking, packaging, and forging welding of two 20t-level blank elements, a 40t-level blank was obtained. Finally the blank is forged into a ring. Specific steps are as follows:

[0057] In the first step, blank primitives are fabricated using conventional...

Embodiment 2

[0067] The target product of this embodiment is the rotor forging. Firstly, the continuous casting method is used to cast a continuous casting slab with a width of 1600mm and a thickness of 300mm, and its steel type is 16Mn. Then cut out the continuous casting slab element with a length of 1600mm, process and clean it, seal and weld it into a preform in a vacuum chamber. After the preform is forged and welded and further forged, a 40t-level blank element is obtained. After surface processing, cleaning, stacking, encapsulation, forging and welding and further forging, 4 pieces of 40t-level rough base units were used to obtain 2 pieces of 80t-level rough base units. After surface processing, cleaning, stacking, packaging, and forging welding, two 80t-level blank elements were used to obtain one 160t-level blank. Finally the blank is forged into a rotor. Specific steps are as follows:

[0068] In the first step, blank primitives are fabricated using conventional construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com